- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

ZL-7066

-

Product name:

-

Fabrics Colour Fastness Test AATCC Six-Color Nine-Grade Color Card

-

Standard:

-

AATCC 15,61/61-2A,132,133,163

-

Apply for industry:

-

Packaging, printing, textile, garments, fabrics, home decor

-

Printing Type:

-

Gravure printing

-

Surface Finish:

-

Film Lamination

-

warranty:

-

2 years

-

Model:

-

ZL-7066

-

Oven:

-

(38±1)°C.

-

Sweat resistance test device:

-

weight 10.0 lb or 4.51kg

-

Glass sheet or PVC board:

-

(sample 57*57 mm)

Quick Details

-

Paper Type:

-

Art Paper, Cardboard, Coated Paper, Corrugated Board, Duplex Board, Fancy Paper, Kraft Paper, Newsprint Paper, Offset paper

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

ZL

-

Model Number:

-

ZL-7066

-

Product name:

-

Fabrics Colour Fastness Test AATCC Six-Color Nine-Grade Color Card

-

Standard:

-

AATCC 15,61/61-2A,132,133,163

-

Apply for industry:

-

Packaging, printing, textile, garments, fabrics, home decor

-

Printing Type:

-

Gravure printing

-

Surface Finish:

-

Film Lamination

-

warranty:

-

2 years

-

Model:

-

ZL-7066

-

Oven:

-

(38±1)°C.

-

Sweat resistance test device:

-

weight 10.0 lb or 4.51kg

-

Glass sheet or PVC board:

-

(sample 57*57 mm)

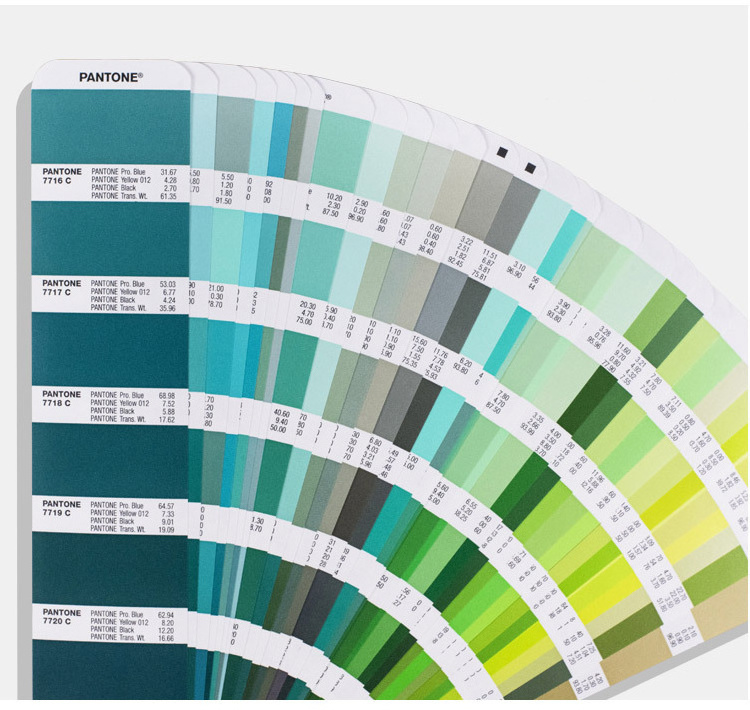

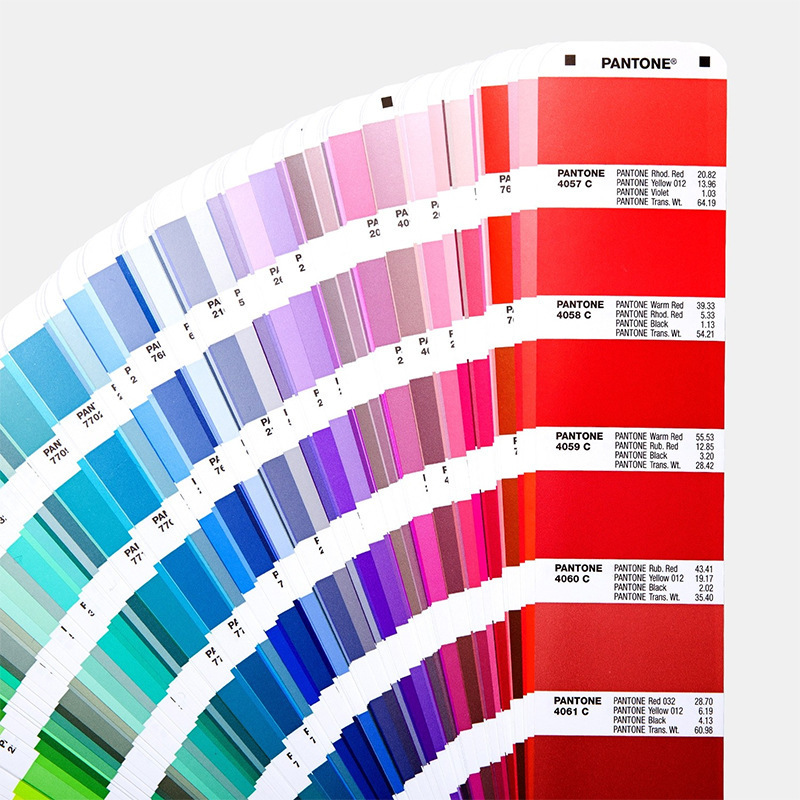

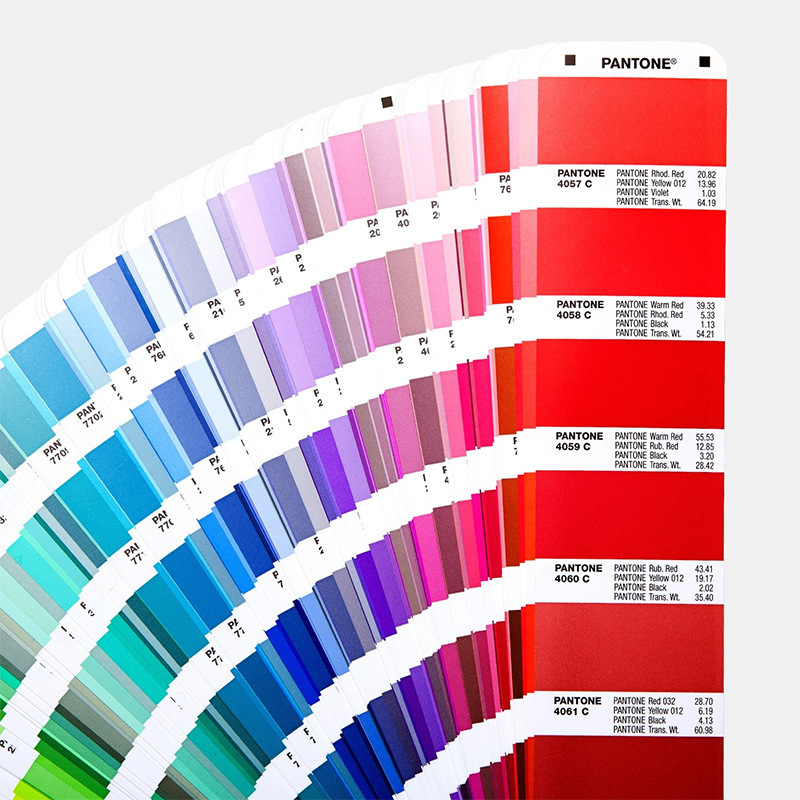

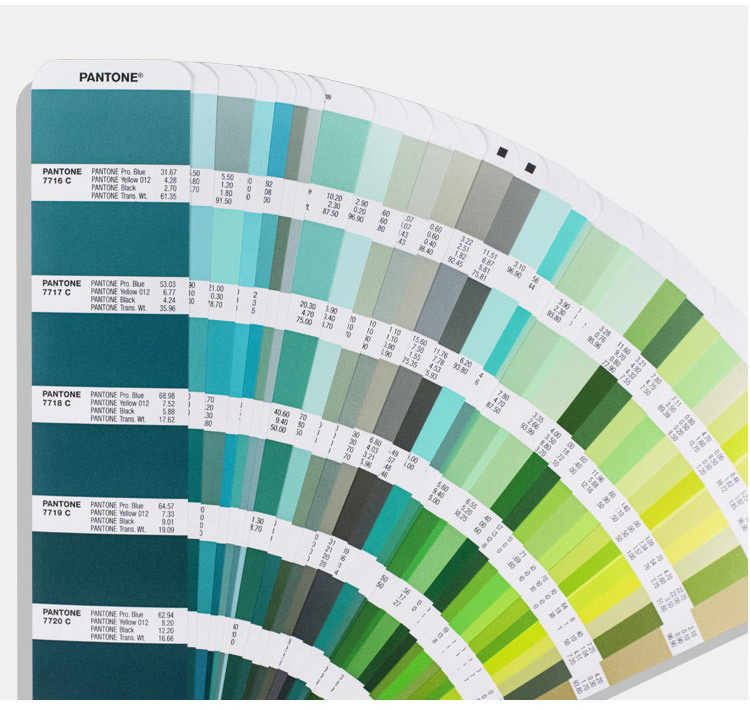

Pantone Color Card Colour Color Chart Formula

AATCC six-color nine-grade color c ard is imported from the United States, divided into 9 grades, also known as AATCC color transfer gray card, used for visual evaluation of color transfer or staining degree, 5 hues (red, yellow, green, blue, purple) , 60 color circle. AATCC assessment method P8.

S tandard: AATCC 15,61/61-2A,132,133,163... or more...

Color fastness refers to the resistance of the color of a textile to various effects during processing and use. The fastness rating is based on the discoloration of the sample and the staining of the undyed backing fabric. Textile color fastness testing is a routine testing item in the intrinsic quality testing of textiles.

The degree of fading of dyed fabrics under the action of external factors (extrusion, friction, washing, rain, exposure, etc.) during use or processing is an important indicator of the fabric. Because the conditions of fabrics in the process of processing and use are very different, the requirements are different.

Therefore, most of the current test methods are simulated tests or comprehensive tests according to the environment and conditions of the action, so the test methods for color fastness are quite extensive.

But looking at the International Standards Organization (ISO), the American Association of Dyers and Chemists (AATCC), Japan (JIS), the United Kingdom (BS) and many other standards, the most commonly used standards are wash resistance, light resistance, friction resistance, sweat resistance, and resistance. Ironing, weather resistance, etc.

Common color fastness tests are:

Color fastness to rubbing, color fastness to light, color fastness to washing, color fastness to sea water, color fastness to dry cleaning, color fastness to heat, migration of dyes in storage, color fastness to acid spot and alkali spot ...

Example: AATCC Test Method 15-2002 Brief Description

This test method is used to determine the perspiration fastness of colored fabrics, and can be used for dyeing, printing and other colored textile fibers, yarns and various fabrics, and can also be used to test dyes on fabrics.

Instruments and Materials

|

1. Glass sheet or PVC board (sample 57×57 mm) |

|

2. Oven (38±1)°C. |

|

3. Sweat resistance test device weight 10.0 lb or 4.51kg |

|

4. AATCC standard multi-fiber cloth No.10 |

|

5. AATCC standard nine color chart |

|

6. AATCC faded gray card and stained gray card |

|

7. Test solution (prepared now, refer to the standard file) |

|

8. PH meter, accuracy to 0.01 |

|

9. Water rolling device (can be pressed by two pieces of glass) |

Test Sample

6×6+2cm sample, with a piece of AATCC No.10 standard multi-fiber cloth attached with the same size, sew the multi-fiber cloth and the sample together, if it is necessary to use the undyed original grey cloth, sew the sample Sandwiched between the multifiber attached fabric and the original grey fabric.

test program

1. Put each test sample in a reagent tank of 9cm×2cm, add artificial sweat to a depth of 1.5cm, completely soak the sample for 30+2min, stir occasionally to make it completely wet. For fabrics that are difficult to wet, pass the wetted samples alternately through a paddle,

until the test solution penetrates completely.

2. After 30+2min, make each sample pass through the rolling mill, the long side is advanced. Make sure that each sample is 2.25+0.05 times the initial weight. Some fabrics cannot maintain this weight after passing through the paddle, so use AATCC blotting paper (white) to keep it within the specified pick rate range.

In order to obtain consistent results, the samples cut from a piece of cloth should have the same rolling rate in the same experiment, and the staining grade will not increase due to the increase of the amount of liquid.

3. Put each test sample on a marked PVC board or ordinary glass sheet, and each piece of multi-fiber cloth should be perpendicular to the long side of the glass sheet.

4. Put the test samples between the 21 PVC sheets attached to the sweat resistance test device. Regardless of the number of samples, 21 glass slides should be put into the experimenter, and then two more glass slides are placed on the top as elastic compensation, and a 3.63Kg weight is placed to make the total pressure of the slides 4.54Kg.

Turn the screw to lock the pressure plate. The perspiration test device was placed vertically in the oven.

5. Put the fixed sample into the oven and bake at 38+1℃ (100+2F) for 6 hours+5 minutes. Check the oven temperature regularly to ensure that the entire experiment has been kept within the specified temperature range.

6. After 6 hours + 5 minutes, take the sample out of the oven, and place the sample and the attached multi-fiber cloth to dry separately, in a treated environment) 21+1℃, 65+5%RH) to dry. Leave it overnight.

ABOUT US

We are Zhongli Instrument Technology Co., Ltd, an instrument Expert, Headquartered in Dongguan, Guangdong, China.since 2007, specialized in manufacturing Lab testing equipments.

Throughout its more than 13 years of history, Our products have sold well in the Europe, America and Southeast Asia market and total more than 80 countries these years,especially favored by European and American countries.

Our equipments cover a wide range of industries, such as rubber and plastics industry, food industry, packaging industry, electronics industry, etc.and are suitable for all scientific research units, quality inspection institutions and academic fields.

In addition to standard machines, our R&D team can customize it for you. Just tell us your needs and we will make you satisfied.

Click here >>>> More Factory Prices and Shipping !!!

1. How to choose the most suitable Mechanical Equipment ?

Our professional team will give you the best suggestion as long as you tell us what kind of test you need to do andthe required specification.

2. What’s the delivery term?

At most of time, we have stock in the factory. If there is no stock, normally, the delivery time is 15~20 working days after deposit receipt. If you are in urgent need, we can consider making special arrangement for you.

3. Do you accept customization service?

Yes, of course, we can not only offer standard machines, but also customized machines

according to your request. Don’t hesitate to tell us your requirement, we will try our best to meet your needs.

4. Can we visit your factory before order?

Yes, we warmly welcome and sincerely invite you or your team to visit our factory, we will help to arrange hotel and pick up you from airport.

5. Do you have customers of our country before?

Now our testing machines have been sold to more than 80 countries, like USA, Canada, Russia,UK, Italy, Germany, European , India, Pakistan, Philippine, Singapore, Malaysia,Thailand , Vietnam, Korea,Saudi Arabia,Brazil...and so on.

6. How about your warranty?

Generally,our warranty is two years. Within the warranty period, we can offer technique support and part parts change, necessarily, our engineers may go to your place for better service.

7. How about the packing for machine, is it safely protected during transportation?

Our machine is packed by standard export wooden box, it won’t be damaged. We’ve delivered many testing machines abroad by sea or by air without damage.

8. What is the order process?

Inquiry - quotation - communication - order confirming - deposit payment - production - testing and debugging - balance payment - packing - delivery - customer receiving - after service.

9. How to install and use the product?

The product is shipped with an operating instructions and video of English version.

Welcome to visit our Official Website:

www.zltester.com

How to contact us?

Send your inquiry details in the below, click " Send " Now!

Click here >>>> More Information !!!