- Product Details

- {{item.text}}

Quick Details

-

Application:

-

kitchen,building,elevator,ect

-

Width:

-

10-2000mm

-

Product name:

-

304 Stainless steel plate

-

Origin:

-

shanghai guangzhou shanxi

-

Surface finish:

-

NO.1 ba 2b hl no.4.ect.

-

Thickness:

-

5mm 4mm 3mm 2mm.ect.

-

Trade term:

-

EX-work,FOB,CFR,CIF

-

MOQ:

-

1Ton

-

Edge:

-

mill edge and slit edge

-

Stock:

-

IN STOCK

-

Payment:

-

TT L/C D/P D/A

-

Type:

-

Plate

-

Certification:

-

ISO

-

Model Number:

-

302 304

-

Length:

-

2000-8000mm

Quick Details

-

Tolerance:

-

±1%

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

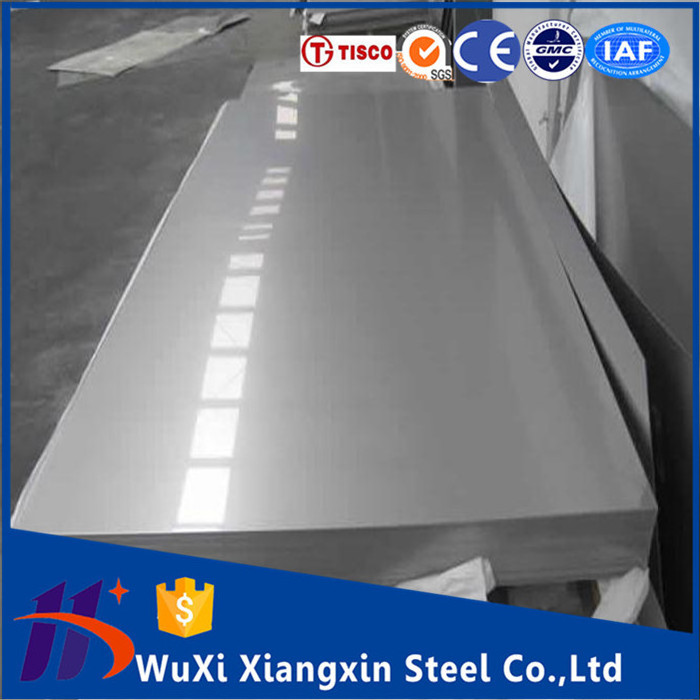

Xiangxin, LISCO TISCO BAOSTEEL POSCO

-

Application:

-

kitchen,building,elevator,ect

-

Width:

-

10-2000mm

-

Product name:

-

304 Stainless steel plate

-

Origin:

-

shanghai guangzhou shanxi

-

Surface finish:

-

NO.1 ba 2b hl no.4.ect.

-

Thickness:

-

5mm 4mm 3mm 2mm.ect.

-

Trade term:

-

EX-work,FOB,CFR,CIF

-

MOQ:

-

1Ton

-

Edge:

-

mill edge and slit edge

-

Stock:

-

IN STOCK

-

Payment:

-

TT L/C D/P D/A

-

Type:

-

Plate

-

Certification:

-

ISO

-

Model Number:

-

302 304

-

Length:

-

2000-8000mm

- Delivery 3 or 5 workdays in Stock

-

Material Grade:302 304

- width 1000 1219 1500 1800 2000mm or as your request

- Thickness:0.2-150mm;

-

Length:2000 2438 2500 3000 6000mm or customized

- Original :Tisco

- Surface:NO.1 2B BA 8K BRUSH HL NO.4 ECT.

- Payment:T/T, L/C, D/P,D/A

| ITEM | Stainless Steel Sheet From China Facotry |

| Brand | RONSCO,BAOSTEEL, JISCO, TISCO, etc. |

| Grade |

201.202.301.302.304.304L.310S.316.316L.321.430.430A.309S.2205.2507.2520.430.630.631 .410.440.904Lect. Or Customized |

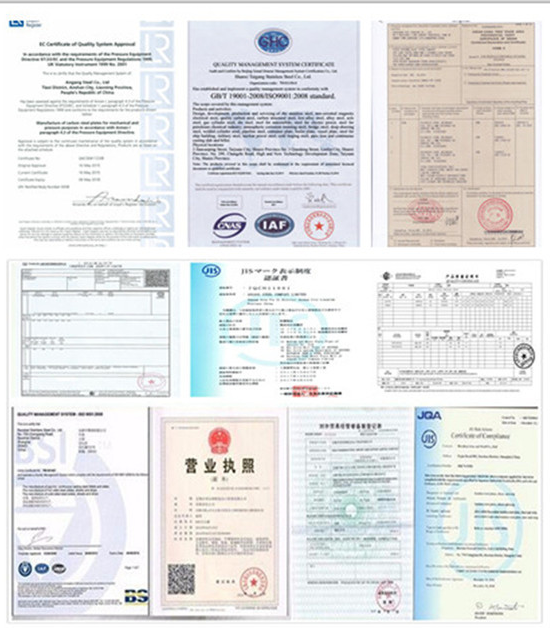

| Certificate |

SGS, BV,IQI,TUV,ISO,etc |

| Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

| Standard | GB, AISI, ASTM, ASME, EN, BS, DIN, JIS |

| Package | Standard export sea-worthy packing or customized |

| MOQ | 1Ton |

| Contact | Contact Evans( MP/WhatsApp/Viber/Skype: 0086-18651134538 ) |

| 201 | ≤0.15 |

≤0.75 |

5.5-7.5 | ≤0.06 | ≤0.03 | 3.5-5.5 | 16.0-18.0 | - |

| 202 | ≤0.15 | ≤1.0 | 7.5-10.0 | ≤0.06 | ≤0.03 | 4.-6.0 | 17.0-19.0 | - |

| 301 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤0.03 | 19.0-22.0 | 24.0-26.0 | - |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 |

12.0-15.0 |

16.0-18.0 | 2.0-3.0 |

| 321 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 9.0-13.0 | 17.0-19.0 | - |

| 630 | ≤0.07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤2.0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0-28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.80 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤0.03 | 0.19-0.22 | 0.24-0.26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.12 | ≤0.75 | ≤1.0 | ≤0.040 | ≤0.03 | ≤0.60 | 16.0-18.0 | - |

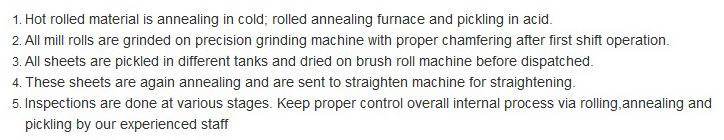

Raw materials are sending to hot rolling units for rolling into different sizes:

Stainless steel maintenance:

(1) Regular clea ning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

Related certificate--stainless steel Plate

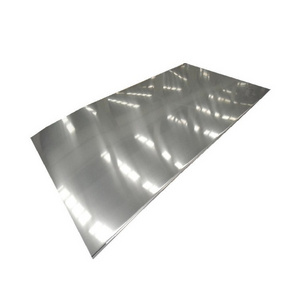

4.Product Photos

Stainless steel Plate

Stainless steel coil

5.Surface--stainless steel Plate

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

|

BA/8K mirror |

Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| Hairline | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

Standard seaworthy package:

1.with plastic cap to protect both ends

2.weaving bag wrapped outside the pipe

3.then pack into wooden case.

delivery detail:5-10 days since received the deposit of L/C draft.