- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

2600kg

-

Size:

-

3.4*0.9*1.8m

-

Power:

-

1.65kw

-

Productivity:

-

30-75kg/h

-

Weight (KG):

-

2600 kg

-

Model:

-

301S

-

Fixed Collar:

-

POM

-

Rotating Collar:

-

SS304

-

Rotating Shaft:

-

SS304

-

Filtrate Tank:

-

SS201

-

Mixed Tank:

-

SS304

-

Stirring Shaft and Paddle:

-

SS304

-

Motor Base:

-

SS304

-

Sludge Inlet Pipe:

-

SS304

-

Support Plate:

-

SS304

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JHM

-

Material:

-

Stretch film or plywood box.

-

Weight:

-

2600kg

-

Size:

-

3.4*0.9*1.8m

-

Power:

-

1.65kw

-

Productivity:

-

30-75kg/h

-

Weight (KG):

-

2600 kg

-

Model:

-

301S

-

Fixed Collar:

-

POM

-

Rotating Collar:

-

SS304

-

Rotating Shaft:

-

SS304

-

Filtrate Tank:

-

SS201

-

Mixed Tank:

-

SS304

-

Stirring Shaft and Paddle:

-

SS304

-

Motor Base:

-

SS304

-

Sludge Inlet Pipe:

-

SS304

-

Support Plate:

-

SS304

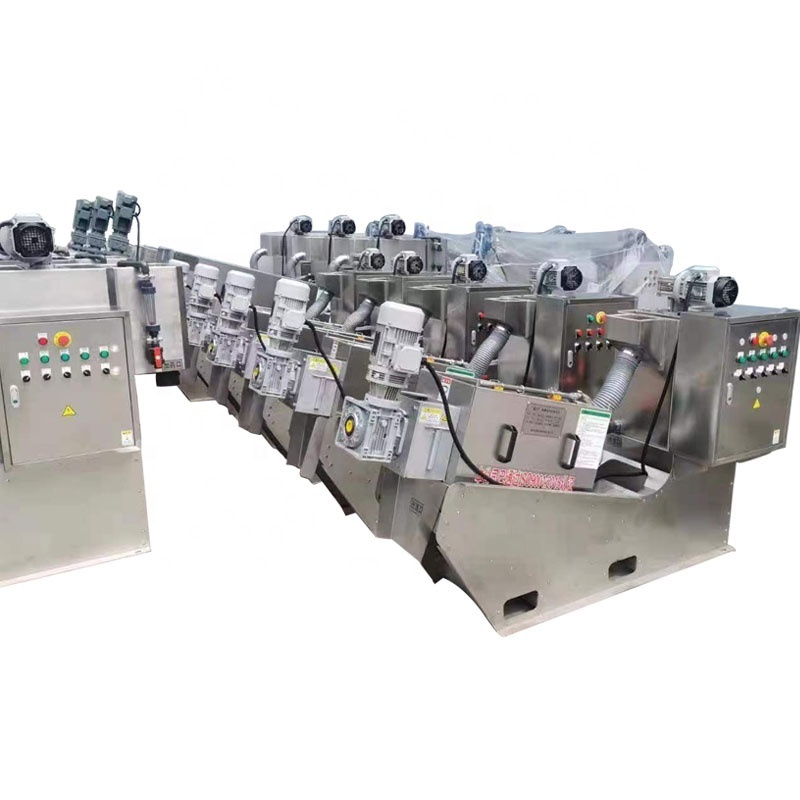

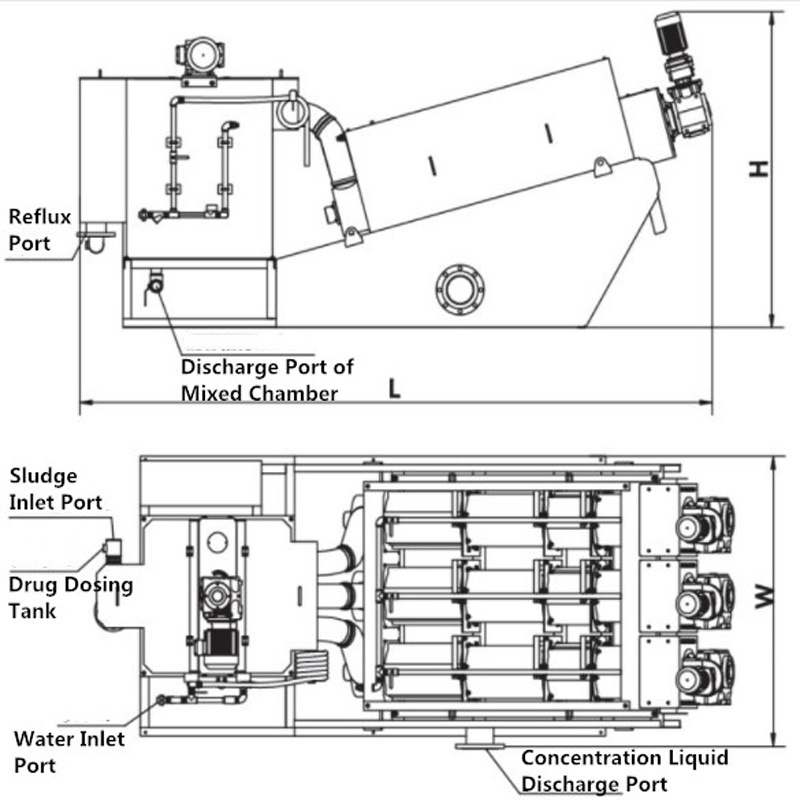

Portable Wuxi Sludge Dewatering Machine Screw Press Small Price

|

Item |

Description |

|||

|

Dimension |

L 3400 ×W 900 ×H 180 0mm |

|||

|

Total Power |

1.65 [kW] |

|||

|

Capacity |

DS30-75kg/h |

|||

|

Feed Sludge Concentration |

||||

|

Feed Sludge Flux |

1m³/h-3m³/h |

|||

|

Max. Chemical Dosing |

360L/h |

|||

|

Power Supply |

Power 1 φ 380V/50Hz |

Control 1 φ220V/50Hz |

||

|

Main Body |

ModelxLength |

Φ 250( inner dia. of fixed collar ) × 1500mm ( validity length ) |

||

|

|

Qty |

1 |

||

|

|

Fixed Collar |

Thickness |

5mm |

|

|

|

|

Material |

POM |

|

|

|

Rotating Collar |

Thickness |

2.75mm |

|

|

|

|

Material |

SS304 |

|

|

|

Frame Plate |

Thickness |

6mm |

|

|

|

|

Material |

SS304 |

|

|

|

|

Processing Method |

Laser cutting nitrogen protection |

|

|

|

Gasket |

Thickness |

3mm |

|

|

|

Main Shaft |

Specification |

Φ 250 |

|

|

|

|

Material |

SS304 |

|

|

|

|

Processing Method |

Endface surfacing high strength alloy |

|

|

|

Connecting Rod |

Specification |

Φ 12x6 |

|

|

|

|

Material |

SS304 |

|

|

Motor |

Model |

K77R37 (vairable frequency speed regulation |

* |

|

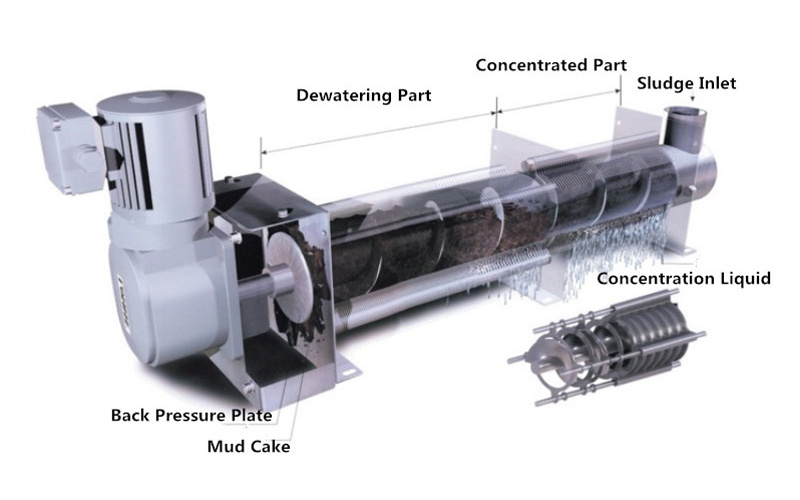

1. S crew stacker dewatering machine mainly treats organic sludge . The sludge produced by the sewage treatment plant is organic sludge, which has a high organic matter content, high moisture content, high viscosity, and is not easy to dewater. The special operating principle of the screw stacker can complete the self-cleaning process when treating organic sludge, without clogging problems, and can ensure the dewatering effect and dewatering efficiency.

2. M otor power of the screw stacker is smaller and the energy consumption is lower. In addition, all the fuselages of the screw stacker are made of 304 stainless steel, the service life of the screw stacker is much higher .