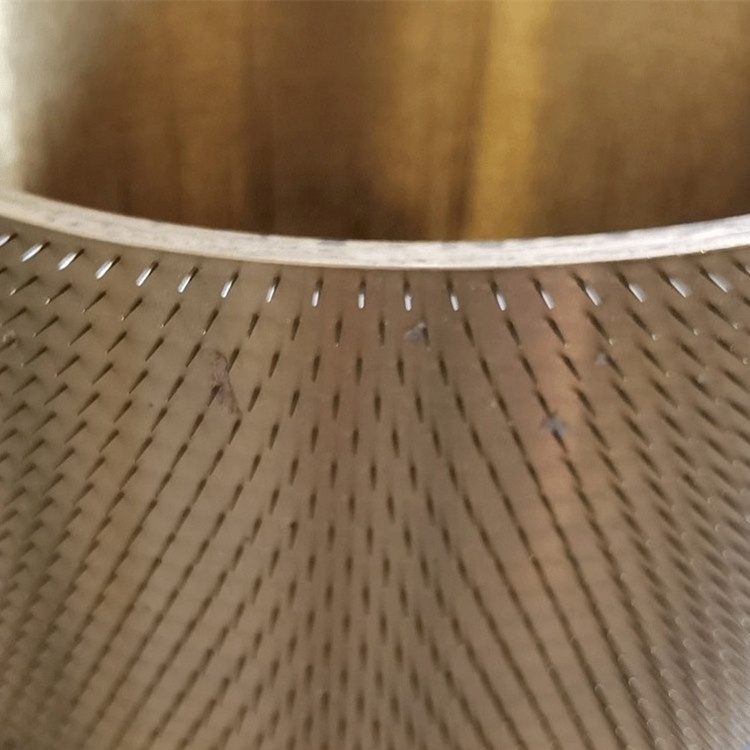

Hot pin perforating is the process of taking a heated, sharpened pin and piercing a substrate with the pin point. This results in a melted hole, where the center of the hole is melted into a re-enforced ring around the punctured hole.

Benefits:

1. Less expensive method of perforating than laser with often similar results

2.Great for perforating all the way across a web

3. Straight forward to install and operate

Simple to maintain

4. Heat helps prevent dusting seen in cold perforating applications

5. Can be used on just about any material

Some benefits from the molten ring style aperture

6. Stronger resulting holes are helpful, especially in brittle material applications

Melted hole will not close back up, and allows for excellent flow control of air, moisture or water

Disadvantage:

1. The center of the hole is pierced and melted, debris can sometimes be an issue, depending on the substrate

2. The welted style hole is not always suitable for the application

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Jieliang

-

Model Number:

-

Pin Perforating

-

Size:

-

Customized

-

Types:

-

Cold Perforation/Hot Perforation

-

Package:

-

Wooden Case

-

Material:

-

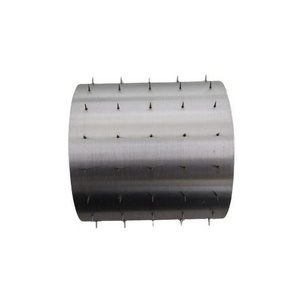

Stainless Steel/Brass

-

Application:

-

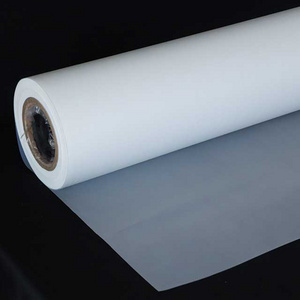

Film Laminate Machine

Quick Details

-

Type:

-

Industrial Brush

-

Bristle Length:

-

Customized

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Jieliang

-

Model Number:

-

Pin Perforating

-

Size:

-

Customized

-

Types:

-

Cold Perforation/Hot Perforation

-

Package:

-

Wooden Case

-

Material:

-

Stainless Steel/Brass

-

Application:

-

Film Laminate Machine

Product Description

Hot rotary pin perforating

Cold rotary pin perforating

Cold pin perforating is the process of taking a sharpened pin and piercing a substrate with the pin point. This usually results in a "volcanic" looking aperture in poly- based materials, which can be beneficial in some applications, such as those that require a

one way valve. Cold perforation is the least expensive and fastest methods of perforating.

Cold rotary pin perforating can be applied continuously, or can be made to work in register or intermittently.

Benefits:

1. Least expensive method of perforating

2. Fastest method of perforating

3. Simple to install and operate

4. Simple to maintain

5. Can be used on just about any material

Disadvantage:

1. Some benefits from a volcanic style apertureDusting can occur in some materials

2. Punctured hole can potentially close back up, but will open again in above normal atmospheric conditionsCold pin perforators can be made from 25mm wide up to 4000mm wide as standard

one way valve. Cold perforation is the least expensive and fastest methods of perforating.

Cold rotary pin perforating can be applied continuously, or can be made to work in register or intermittently.

Benefits:

1. Least expensive method of perforating

2. Fastest method of perforating

3. Simple to install and operate

4. Simple to maintain

5. Can be used on just about any material

Disadvantage:

1. Some benefits from a volcanic style apertureDusting can occur in some materials

2. Punctured hole can potentially close back up, but will open again in above normal atmospheric conditionsCold pin perforators can be made from 25mm wide up to 4000mm wide as standard

Product Images

Hot Searches