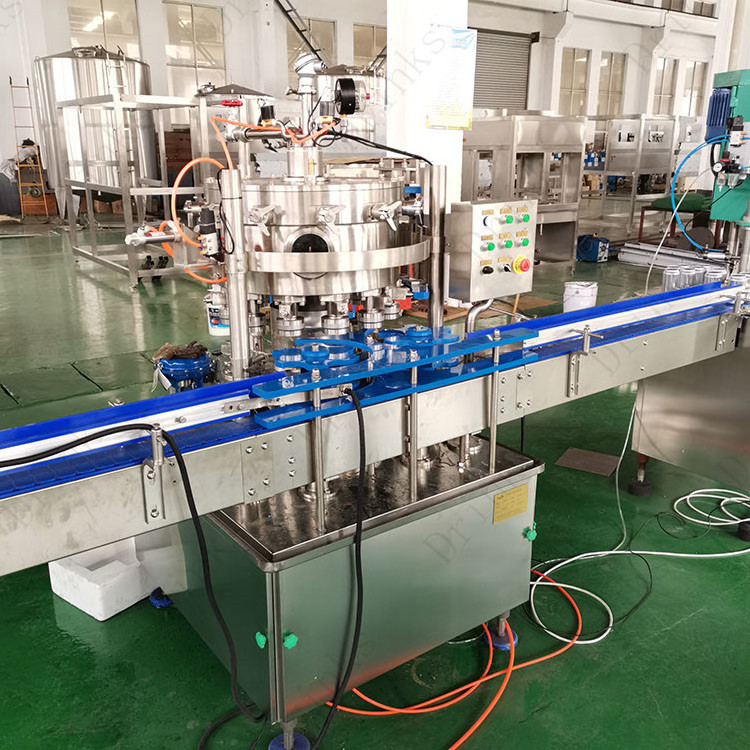

The machine adopts equal pressure filling. The isostatic filling machine first inflates the packaging container to make the internal gas pressure equal to the gas pressure in the liquid storage tank, and then fills the liquid into the filling equipment in the packaging container.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V 50HZ (Customized)

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Drinks

-

Dimension(L*W*H):

-

1065*1000*1850mm

-

Weight:

-

450Kg

-

Product name:

-

Can filling machine

-

Filling material:

-

Gas liquid

-

Bottle type:

-

PET / plastic / aluminum /tin cans

-

Filling volume:

-

150-750ml

-

Suitable cans diameter:

-

50-95mm(Customized)

-

Can diameter height:

-

80-290mm

-

Material:

-

Stainless steel 304/316

-

Capacity:

-

1500-2500 CPH

-

Filling Accuracy:

-

99%

-

Certification:

-

CE

Quick Details

-

Machinery Capacity:

-

2000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Metal

-

Filling Material:

-

Beer, Carbonated drinks

-

Voltage:

-

220V/380V 50HZ (Customized)

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Drinks

-

Dimension(L*W*H):

-

1065*1000*1850mm

-

Weight:

-

450Kg

-

Product name:

-

Can filling machine

-

Filling material:

-

Gas liquid

-

Bottle type:

-

PET / plastic / aluminum /tin cans

-

Filling volume:

-

150-750ml

-

Suitable cans diameter:

-

50-95mm(Customized)

-

Can diameter height:

-

80-290mm

-

Material:

-

Stainless steel 304/316

-

Capacity:

-

1500-2500 CPH

-

Filling Accuracy:

-

99%

-

Certification:

-

CE

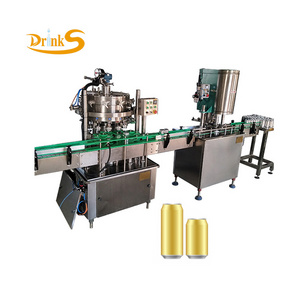

Product Description:

This series of canned carbonated beverage filling machine is an advanced isobaric filling machine based on the introduction, digestion and absorption of advanced foreign technology. It is mainly used in beer, soda, cola, sparkling wine, and canned drinks containing sparkling drinks. The utility model has the advantages of advanced structure, balanced work, reliability, safe operation, convenient maintenance, stepless speed regulation of speed regulation and high production efficiency.

Machine characteristics:

1. The machine has variable frequency speed regulation, fast filling speed, overload protection device, card bottle stop, soft start, and elastic bottle holder to reduce bottle damage.

2. The filling quantity is adjusted by electric synchronous stepless adjustment. Pressing the addition and subtraction adjustment button can adjust the filling amount. The digital display accurately displays the instantaneous filling capacity, and has a manual fine adjustment system, which is more filling capacity. accurate.

3. The filling range of the machine is large, and the filling amount can be adjusted between 125-550 mm.

4, the applicable bottle height range, can be adjusted between 150-350 mm (out of range can be customized)

5. The main seals are made of imported silica gel, and the main parts are made of 304 stainless steel that meets food hygiene standards.

Hydraulic cylinder:

Filling valve:

1. The machine adopts a measuring cup type quantitative filling valve with high filling precision.

2. The liquid flows down the bottle wall during filling, which effectively controls the foam caused by liquid impact during

filling and prevents liquid spillage.

Control button:

The host adopts advanced control technology, and the main electrical components and pneumatic components are world famous brand

products.

|

Model

|

Heads

|

Productivity

(BPH)

|

Filling volume

(ML)

|

Filling accuracy

|

Motor Power

(KW)

|

Dimensions

(MM)

|

|

YLG-12

|

12

|

500-3000

|

150-750

|

99%

|

0.75

|

1065*1000*1850

|

|

YLG-18

|

18

|

3000-4500

|

150-750

|

99%

|

1.1

|

1250*1200*2000

|

|

YLG-24

|

24

|

4000-5500

|

150-750

|

99%

|

1.5

|

1400* 1300*2000

|

Q:Will these products be what I want?

A:

If not, you can also visit our homepage and select other products. Our website is:

http://drinksmachinery.en.alibaba.com

What kind of service can your company provide?

A:

Throughout the cooperation process, our company can provide the following three services.

1.Sample service

We can send you a video of the work of this machine.

You are very welcome to visit our company and check the operation of the machine on site. We will send someone to pick you up at the airport.

2. Customized service

We can customize the machine according to the customer's requirements (such as material, power, filling type, bottle size, etc.), and our engineers will also provide professional advice to help customers better establish the ideal factory.

3. After sales service

After receiving the final payment, we will provide the bill of lading in time to ensure that the customer receives the goods as soon as possible.

Once you have completed all the preparations, we will send engineers to your factory to install the machines and train your staff for free until they are able to operate the machine well.

We can provide one year warranty and spare parts, and free lifetime technical service.

1. Q: Are you a factory or a trading company?

A:

We are a factory that produces a complete set of raw water treatment equipment and juice filling production lines. Our company has 5 years of production experience. The factory area is approximately 5,000 square feet. Customers in nearly 20 countries have used our equipment.

2. Q: Where is your factory? How do I get there?

A:

The address of our company is Leyu Town, Zhangjiagang City, Jiangsu Province. It is about one and a half hours drive from Shanghai Hongqiao Airport and 40 minutes from Wuxi High Speed Rail. Welcome Chinese and foreign customers to visit our company.

3. Q: How long is the warranty period of your machine?

A:

After the device is accepted, it provides a 12-month warranty, the control system provides a 12-month warranty, free accessories and timely and effective service. After the warranty period, provide extensive technical support and lifetime after-sales service.

4. Q: What are the characteristics of your company?

A:

We provide turnkey projects for our customers, including pre-sales and after-sales services, providing complete production lines, designing bottle samples, providing layout drawings free of charge, providing auxiliary material supply information, machine installation and commissioning, and employee training.