- Product Details

- {{item.text}}

Quick Details

-

MF:

-

C3H6N6

-

EINECS No.:

-

203-615-4

-

Place of Origin:

-

Shandong, China

-

Appearance:

-

white powder

-

Application:

-

Wood glue/toilet seat adhensive

-

Brand Name:

-

Grace

-

Model Number:

-

E1

-

purity:

-

≥99%

-

Color:

-

white

-

Usage:

-

wood panel bonding/wood glue/laminating glue

-

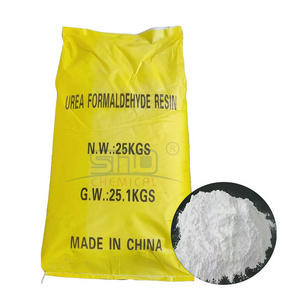

Package:

-

25/500/1000kg Plastic Woven Bags

-

Grade:

-

Industrail Grade

-

Boiling point:

-

354

-

Sample:

-

Availiable

-

Storage:

-

Cool Dry Place

Quick Details

-

CAS No.:

-

258-96-3

-

Purity:

-

99%

-

Other Names:

-

modified urea formaldehyde resin

-

MF:

-

C3H6N6

-

EINECS No.:

-

203-615-4

-

Place of Origin:

-

Shandong, China

-

Appearance:

-

white powder

-

Application:

-

Wood glue/toilet seat adhensive

-

Brand Name:

-

Grace

-

Model Number:

-

E1

-

purity:

-

≥99%

-

Color:

-

white

-

Usage:

-

wood panel bonding/wood glue/laminating glue

-

Package:

-

25/500/1000kg Plastic Woven Bags

-

Grade:

-

Industrail Grade

-

Boiling point:

-

354

-

Sample:

-

Availiable

-

Storage:

-

Cool Dry Place

Urea formaldehyde resin is the condensation polymerization of urea and formaldehyde under the action of catalyst (alkaline or acidic catalyst) to form initial urea formaldehyde resin, and then form insoluble and non fusible end-stage thermosetting resin under the action of curing agent or assistant. The cured urea formaldehyde resin is lighter in color than phenolic resin, translucent, resistant to weak acid and alkali, good insulation performance, excellent wear resistance and low price. It is the most used variety in adhesives, especially in the manufacture of various wood-based panels in wood processing industry. Urea formaldehyde resin and its modified products account for about 90% of the total amount of adhesives. However, urea formaldehyde resin is easy to decompose in case of strong acid and alkali, with poor weather resistance, poor initial viscosity, large shrinkage, brittleness, water resistance and easy aging. There is a problem of formaldehyde release in the manufacturing and use of wood-based panels produced by urea formaldehyde resin, so it must be modified.

Mainly usage

It can be used for products with low requirements for water resistance and dielectric performance, such as plug-in board, switch, machine handle, instrument shell, knob, daily necessities, decorations, mahjong card and toilet cover. It can also be used for the manufacture of some tableware.

Urea - formaldehyde resin is the most widely used in adhesives Especially in the manufacture of various wood-based panels in the wood processing industry, urea formaldehyde resin and its modified products account for about 90% of the total amount of adhesive.

ATTENTION:

Because urea formaldehyde resin has some disadvantages, such as poor initial viscosity, large shrinkage, large brittleness, water resistance, easy aging, releasing formaldehyde, curing, releasing formaldehyde, polluting the environment and damaging health, it must be modified to improve its performance and expand its application. The modification methods are listed as follows:

1. Increase initial viscosity

To improve the initial viscosity of urea formaldehyde resin, modifiers such as polyvinyl alcohol, polyethylene glycol and hydroxymethylcellulose can be added, but the price of these substances is high. Therefore, starch can be selected, especially when starch is added at the beginning of urea formaldehyde resin synthesis, and the effect is better. In the synthesis process, starch may be hydrolyzed to produce various dextrins. Due to the high relative molecular weight of starch and high viscosity after dissolution, urea formaldehyde resin with high viscosity can be prepared by adding a small amount. At the same time, hydroxyl, hydroxymethyl and aldehyde groups on starch molecular chain may participate in the synthesis reaction of urea formaldehyde resin, which not only improves the initial viscosity, but also improves the bonding strength and storage stability.

2. Reduce shrinkage

Urea formaldehyde resin has large curing shrinkage, is easy to crack, and the adhesive layer produces internal stress, which reduces the viscosity and strength. In order to reduce the shrinkage of urea formaldehyde resin during curing, some fillers are usually added to the resin glue, such as flour, starch, blood powder, a-cellulose powder, wood powder, soybean powder, etc.

3. Reduce brittleness

In order to reduce brittleness and increase toughness, polyvinyl alcohol, polyvinyl formal solution, polyvinyl acetate emulsion, VAE solution can be added, and the initial viscosity and aging resistance can also be improved.

4. Improved water resistance

When synthesizing urea formaldehyde resin, adding a small amount of melamine, phenol, Resorcinol, alkyl amine and sugar aldehyde can effectively improve the water resistance of urea formaldehyde resin. Adding aluminum sulfate and aluminum phosphate as crosslinking agent can also significantly improve the water resistance. Adding wood flour, flour, soybean flour, iron oxide, expansive soil and other fillers can also improve the water resistance.

The urea formaldehyde resin was modified with phenol, the benzene ring structure was introduced into the resin, the water absorption group of the resin was closed, and the water resistance and aging resistance of the resin were significantly improved. Resorcinol or melamine can also be added to the curing agent, and acrylic copolymer emulsion can be blended with urea formaldehyde resin to improve water resistance.

5. Improve bonding strength

The use of multi-component composite additives such as polyvinyl alcohol and phenol can improve brittleness, water resistance and bonding strength. The shear strength of the urea formaldehyde resin is more than 10 times that of the original urea formaldehyde adhesive, and the water resistance and boiling resistance are greatly improved.

According to different application requirements, the properties of urea formaldehyde resin can be significantly improved by adding modifiers.

Package: 25kg/500kg 1000kg pp pe bag or customeised (suggest 25kg/bag anti blocking)

Delivery time: 1-3 days after received the advanced payment.