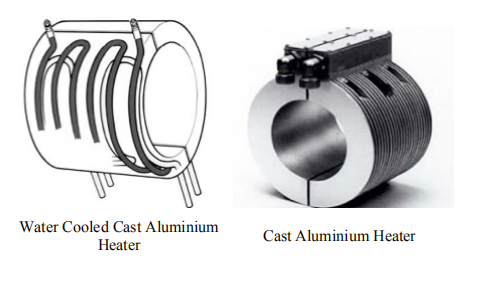

Cast band heaters (Cast-in) are available in Aluminium (400ºC), Brass (600ºC) and Bronze (700ºC). Cast aluminium water-cooled units are the most common. The

casting contains both Incoloy sheathed heating elements and stainless steel cooling tubes. The heaters are available with bolt clamping or separate stainless steel strap clamping. Heating elements are supplied standard with threaded stud terminals for electrical connections. Sheet metal terminal boxes and other termination options are available.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

VINSON

-

Dimension(L*W*H):

-

customized

-

Weight:

-

according the size to

-

Working Temperature Range:

-

30 - 350

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

Local Service Location:

-

None

-

Showroom Location:

-

None

-

After-sales Service Provided:

-

Free spare parts, Video technical support, Online support

-

Marketing Type:

-

Hot Product 2019

-

Shape:

-

plate, band, ring and so on

-

Alloy material:

-

alloy, copper, iron and so on

-

Heating elements:

-

tubular heater

-

Wattage tolerance:

-

+5%, -10%

-

Resistance tolerance:

-

+10%, -5%

-

Max operating temp:

-

300℃

-

Dimension tolerance:

-

±1 mm

-

Terminal type:

-

plug, screw, leadn wire and so on

-

Application:

-

extruder, injection molding machine

-

Certification:

-

CE, ISO9001, Rohs

Quick Details

-

Type:

-

Air Heater

-

Power Source:

-

Electric

-

Voltage:

-

customized

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

VINSON

-

Dimension(L*W*H):

-

customized

-

Weight:

-

according the size to

-

Working Temperature Range:

-

30 - 350

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

Local Service Location:

-

None

-

Showroom Location:

-

None

-

After-sales Service Provided:

-

Free spare parts, Video technical support, Online support

-

Marketing Type:

-

Hot Product 2019

-

Shape:

-

plate, band, ring and so on

-

Alloy material:

-

alloy, copper, iron and so on

-

Heating elements:

-

tubular heater

-

Wattage tolerance:

-

+5%, -10%

-

Resistance tolerance:

-

+10%, -5%

-

Max operating temp:

-

300℃

-

Dimension tolerance:

-

±1 mm

-

Terminal type:

-

plug, screw, leadn wire and so on

-

Application:

-

extruder, injection molding machine

-

Certification:

-

CE, ISO9001, Rohs

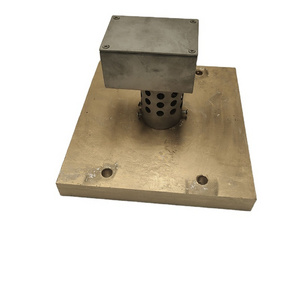

Cast In heaters for all plastics processing applications including, air and liquid cooled barrel heaters, L-shaped heaters, vent cut out heaters, heat only cast in barrel heaters, air cooled with shroud, hollow cast nozzle heaters, and cooling jackets for cast in barrel heaters.

|

Product Name

|

|

Die Casting Aluminum Band Heater

|

|

||

|

Thickness

|

|

20mm, 30mm, 35mm, or customized

|

|

||

|

Maxi Working Temp

|

|

300°C

|

|

||

|

Voltage

|

|

120V, 240V, 480V, 600V or customized

|

|

||

|

Power

|

|

50-2000W, or customized

|

|

||

LIQUID COOLED CAST-IN BARREL HEATERS.

FIN CAST-IN BARREL HEATERS.

Fin Cast Heaters contain Incoloy sheathed elements to provide the heating. The fin offer a large surface area for airflow to act as the cooling medium. These heaters are

intended to be used with sheet metal or cast shrouds. The heaters are available with bolt clamping or separate stainless steel strap clamping.

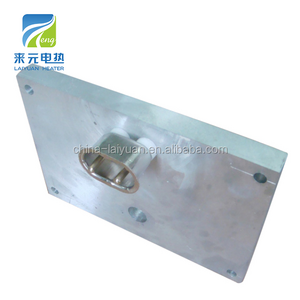

CAST ALUMINIUM HEATER PLATE.

Cast plates and platens are available in virtually any shape and in a huge variety of sizes. They are available in any material and can be offered with heating and cooling

options. Mounting holes, notches, and any number of machining options and surface finishes are available.

Applications.

• Heating plates for presses

• Extruder dies and sheaths

• Heating plates for homogeneous heating (rubber, aerated concrete curing)

• Sealing on packaging lines

• Mills

Advantages.

•Gravity moulding ensures an excellent material homogeneity and thus a perfect heat transfer.

• Constant surface temperature is achieved through appropriate forming

• As this is indirect heating, the heating, the heating resistance is protected. The solid or fluid to be heated is not in contact with the resistance.

• High protection against corrosion

• The end-to-end control of the design and production chain alloows us to deliver a product which suits your process perfectly

|

Packaging

|

|

|

|

Size

|

150(L) * 150(W) * 150 (D)

|

|

|

Weight

|

500KG of Belt vulcanizing machine casting aluminum heating plate Die casting plate Cast heater

|

|

|

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

|

Yancheng Vinson Technology Co., Ltd

was established in 2001 and has about 20 years' production history. We have been engaged in the development, design, production and sales in one of the sales of industrial technology company, according to the customer needs, provide tailored solution of design, committed to the electric heating and temperature measurement in the field of development.

"Quality is in my hand, Customer is in my heart" Quality is our culture, Our products have been exported to Europe, America, Asia, Mid East etc more than 200 countries. We are extensively used in electric heating and other industries. We hope our products and services can benefit your company, and our cooperation can be mutually beneficial win-win situation.