- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

customized

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Zhongtuo

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

10500mm*1400mm*1500mm

-

Weight:

-

6.5 kg

-

Feeding width:

-

customized

-

Product name:

-

Metal Scaffold Plank Deck Rolling Forming Machine for building on sale

-

Usage:

-

Color Steel Construction

-

Company:

-

Cangzhou Zhongtuo

-

Pressing:

-

YangLi pressing machine

-

Cutting:

-

Hydraulic shearing

-

Transmission:

-

Gearbox

-

Driving:

-

Gearbox

-

Forming:

-

Rolling forming

-

Profile:

-

can be designed as your requirement

-

Control system:

-

PLC Control

Quick Details

-

Type:

-

roll forming machine for building

-

Tile Type:

-

steel or other material

-

Production Capacity:

-

12-18m/min

-

Rolling thinckness:

-

customized

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Zhongtuo

-

Voltage:

-

customized

-

Dimension(L*W*H):

-

10500mm*1400mm*1500mm

-

Weight:

-

6.5 kg

-

Feeding width:

-

customized

-

Product name:

-

Metal Scaffold Plank Deck Rolling Forming Machine for building on sale

-

Usage:

-

Color Steel Construction

-

Company:

-

Cangzhou Zhongtuo

-

Pressing:

-

YangLi pressing machine

-

Cutting:

-

Hydraulic shearing

-

Transmission:

-

Gearbox

-

Driving:

-

Gearbox

-

Forming:

-

Rolling forming

-

Profile:

-

can be designed as your requirement

-

Control system:

-

PLC Control

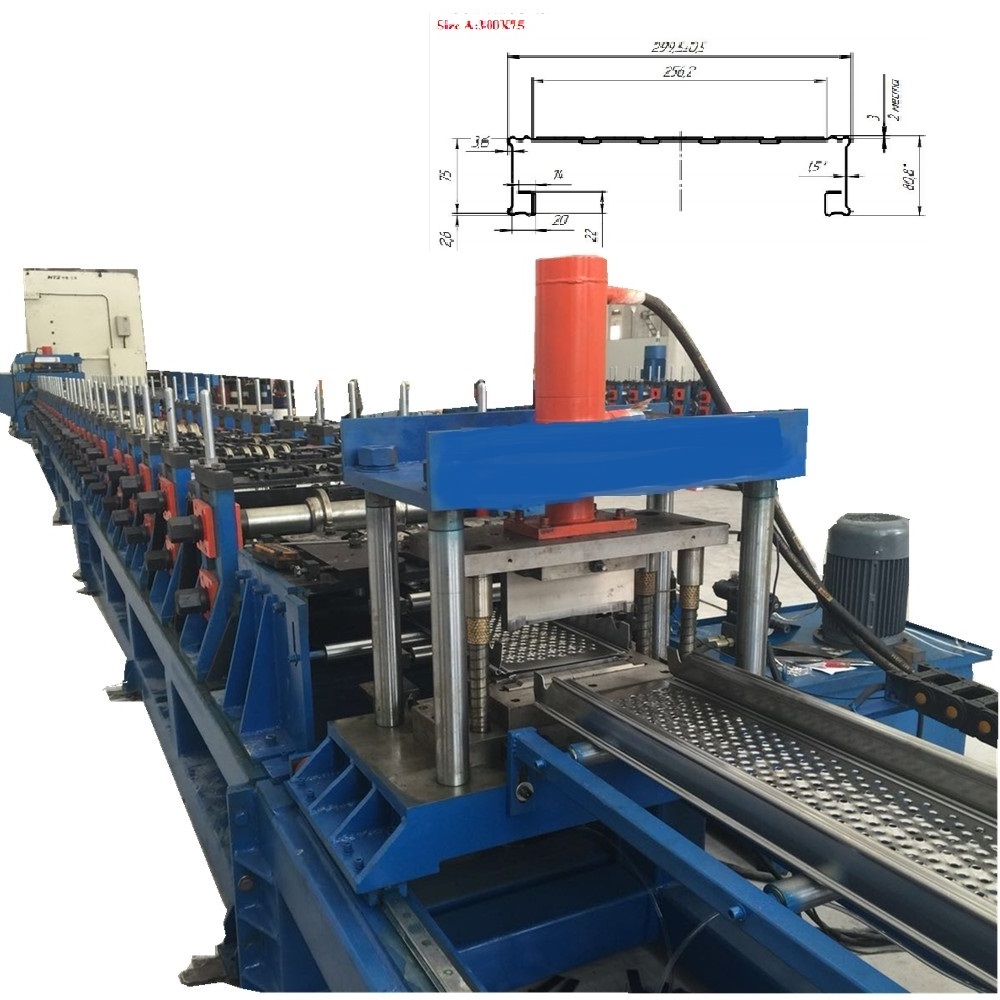

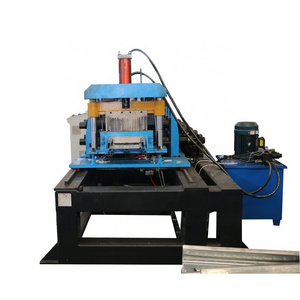

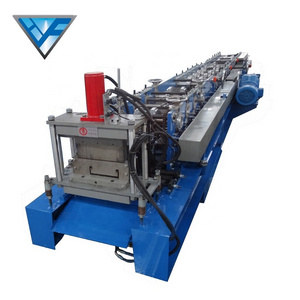

Metal Scaffold Plank Deck Rolling Forming Machine for building on sale

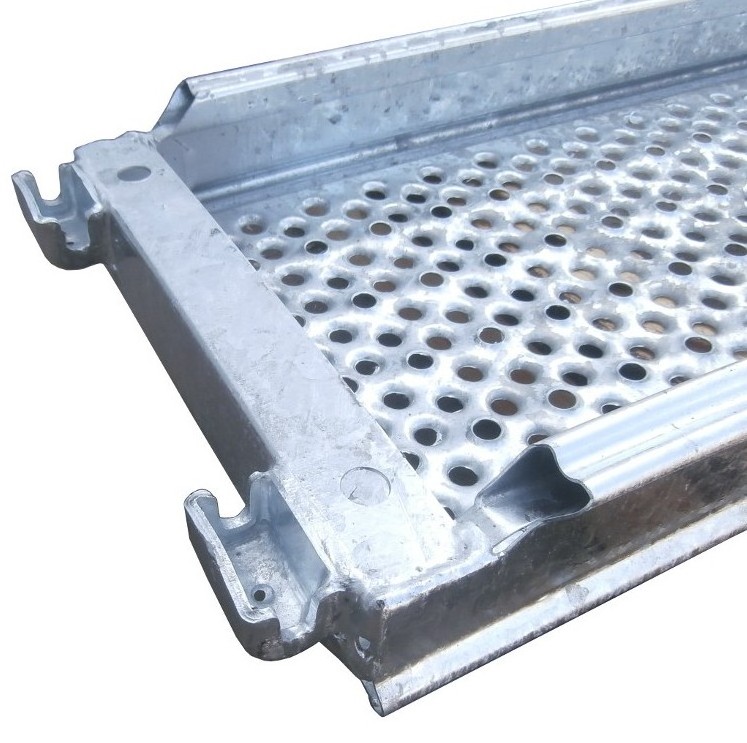

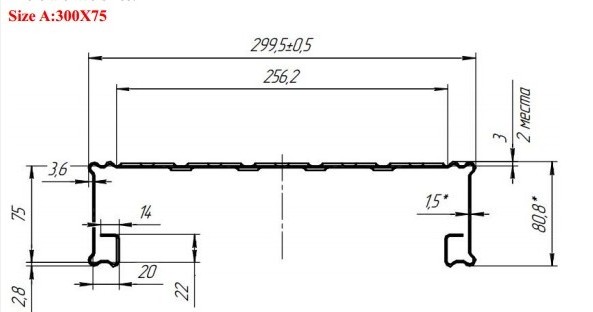

Metal Scaffold Plank Deck Rolling Forming Machine is designed to make many sizes of scaffold plank decking panels in batch and fully autoamtic. The whole production line is controlled by PLC, through PLC you can conotrol metal scaffold plank decking working speed, production quantity and also the length. Scaffold Metal Decks and Steel Planks are made in Galvanized and Painted with Plain Ends and Hook-on for Scaffolding System, Pipe and Fitting Scaffolding, the material thickness is from 0.8 to 1.5mm. In the market, there are lots of metal decking types, take the following profiles for example:

When using of the metal decking:

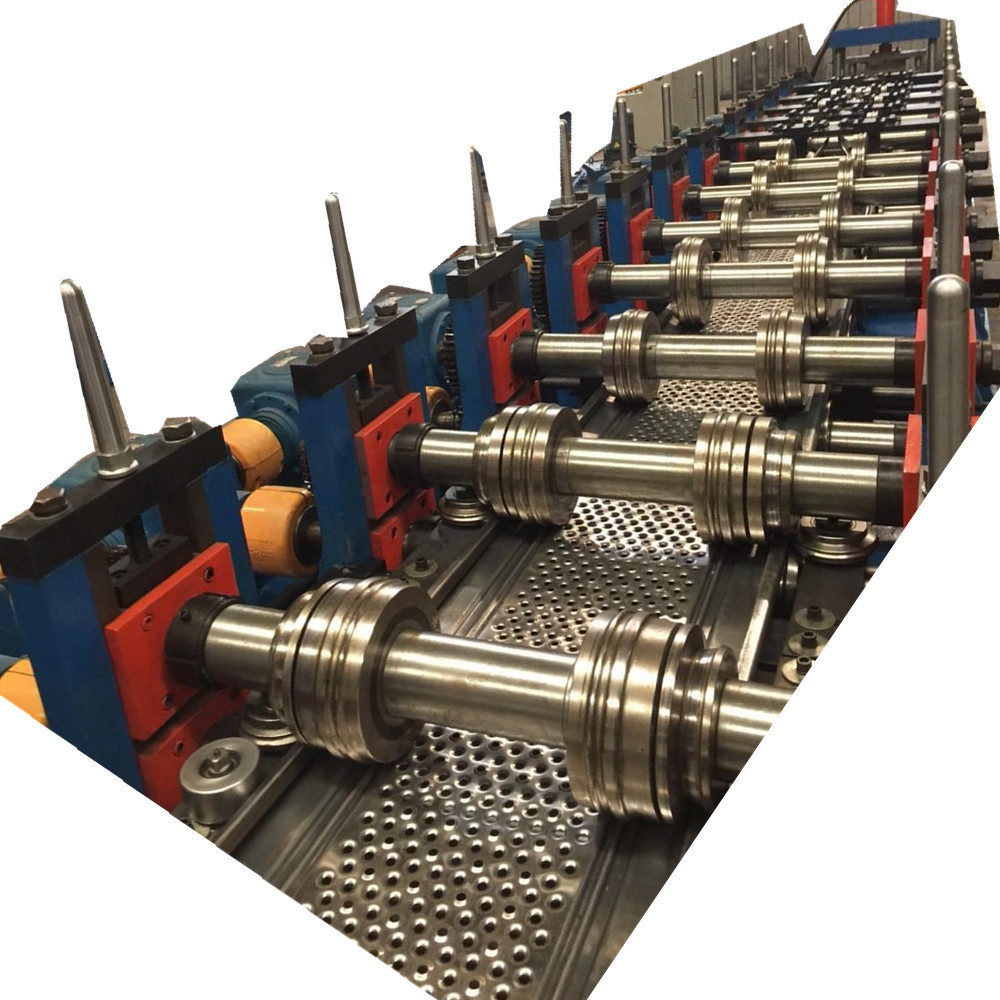

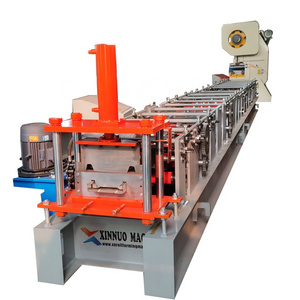

Metal Scaffold Plank Deck Rolling Forming Machine is designed like following :

Metal Scaffold Plank Deck Rolling Forming Machine is composed by the fllowing elements:

Passsive decoiler, leveling machine, servo coil feeder, punching machinne, roll forming machine, hydraulic System, shearing system, runout table, and PLC control system.

Machine working process:

Decoiler-->leveling-->servo coil feeding-->punching system-->roll forming machine-->sizing and shearing System--> runout table

Machine working area requirements:

| Area needed: 35×3.0×5 meter long. |

| Machine working direction: from left to right |

| Hydraulic oil: 46# oil |

| Gear oil: 18 # hyperbolic gear oil |

PLC CONTROL SYSTEM of metal decking roll forming machine:

The PLC control system, touch screen interface. The operator through the procedures for setting the automatic operation (programmable control and process control monitoring and Implementation for the

operator to control production line and modify the control parameters, and real-time monitoring the running state of the equipment, operation parameters and fault indication etc.. Part length digital setting, the length of the workpiece can be adjusted. Real time monitoring equipment

Operation status and fault indication.Operation mode has two kinds of manual / automatic. With manual, automatic switching function: in manual mode, single operation, convenient maintenance; in the automatic mode, the entire production run, startup sequence; across the board with emergency stop button, easy to handle emergencies to ensure equipment and the safety of the operator.

More details pictures of the metal decking machine:

For this machine, if you need to know more information, please contact us at any time.

Q1. What's your payment terms and delivery time?

A1:

30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery.

Of course your payment terms are acceptable.

After we get down payment, we will arrange production. About 30-45 days for delivery.

Q2. Do you have after-sales support?

A2: Yes, we are happy to provide advice and we also have skilled technicians available across the world.

Q3. Do you sell only standard machines?

A3: No, most of our machines are built according to customers specifications, using top brand components.

Q4. What will you do if the machine is broken?

A4: W

e provide 18 months

free warranty

and

free technical support

for the whole life of any machine.

If the broken parts can't repair, we can send the new parts

replace the broken parts freely, but you need pay the express cost by yourself.

If it is beyond the warranty

period,

we can negotiate to solve the problem, and we supply the technical support for the whole life

of the equipment.

Q5. Can you be responsible for transport?

A5: Yes, please tell me the destination port or address. we have rich experience in transporting.

Q6. How to visit your company?

A6: 1) Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour).

2) Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours),

then we can pick up you.