- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

29400

-

Product name:

-

Four Shaft Waste Recycling Shredder Machine

-

Application:

-

waste recycling requirements of various industries

-

Input Size:

-

customized

-

Function:

-

scrap plastic metal Recycling Machine

-

Advantage:

-

Easy Operation High Efficiency

-

Certification:

-

CE ISO TUV

-

Key words:

-

Four Shaft Plastic Shredder

-

Suitable material:

-

Plastic,copper and aluminum plate, and other scrap metal materials

-

Final product:

-

standard-reaching rate is higher than 95%.

-

Usage:

-

electronic waste, plastic, metal, wood, waste rubber,

Quick Details

-

Place of Origin:

-

Henan

-

Brand Name:

-

Aite

-

Power (kW):

-

164

-

Weight (KG):

-

29400

-

Product name:

-

Four Shaft Waste Recycling Shredder Machine

-

Application:

-

waste recycling requirements of various industries

-

Input Size:

-

customized

-

Function:

-

scrap plastic metal Recycling Machine

-

Advantage:

-

Easy Operation High Efficiency

-

Certification:

-

CE ISO TUV

-

Key words:

-

Four Shaft Plastic Shredder

-

Suitable material:

-

Plastic,copper and aluminum plate, and other scrap metal materials

-

Final product:

-

standard-reaching rate is higher than 95%.

-

Usage:

-

electronic waste, plastic, metal, wood, waste rubber,

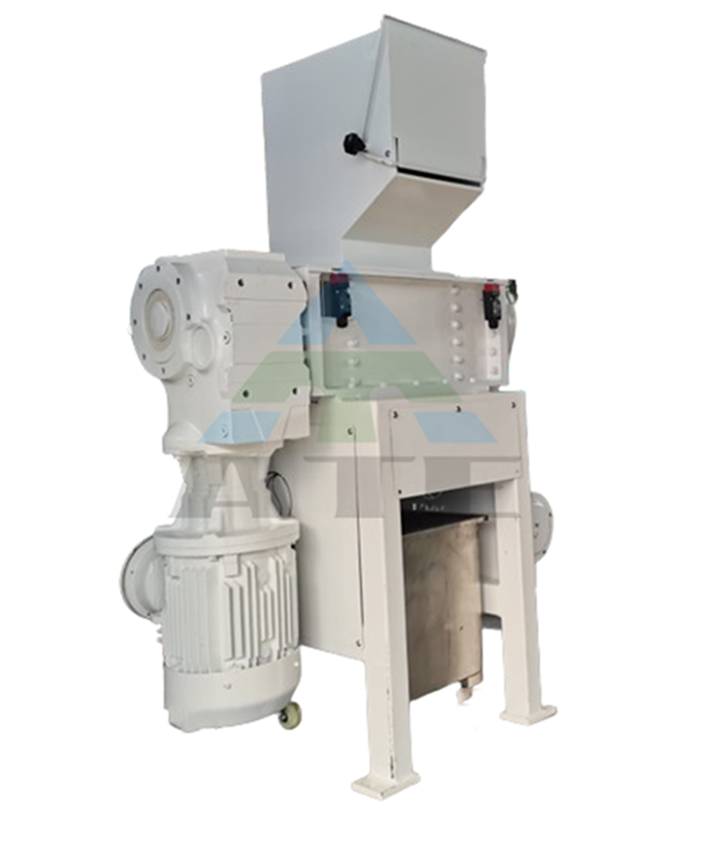

Product Overview

Four shaft shredder machine

/

Wood pallet cardboard crusher shredder

The four-shaft shredder has been designed for a wide array of applications and industries, suitable for shredding solid material such as E-waste, metal, wood, plastic, scrap tires, packaging barrel, pallets, etc. Depending on input material and the following process the shredded material can be used directly or go into the next step of size reduction.

It is widely used in industry waste recycling, medical recycling, electronic recycling, pallet recycling, municipal solid waste recycling, plastic recycling, tire recycling, papermaking industry and etc.

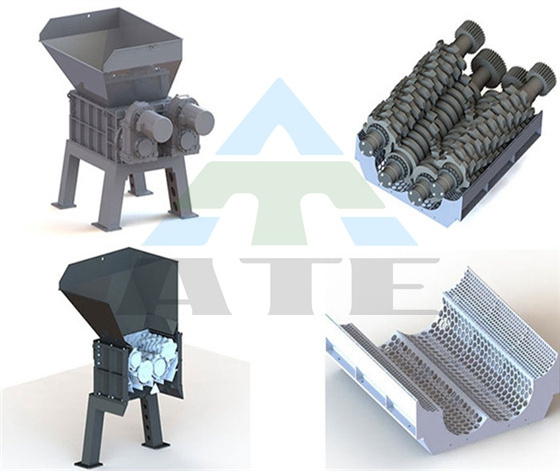

working principle

The four-shaft shredders use a two-axis independent drive so that the production of materials to produce the corresponding pressure, to achieve automatic feeding function, a unique knife shaft structure and a four-corner rotary tool, low-speed high torque in the production process, there will be no winding shaft, or stuck phenomenon of the device, thereby increasing the production efficiency, the device is suitable for all kinds of toughness, high viscosity material crushing.

Knife Details Of The Metal Shredder

Everything can be shredded

Applicable industrial Waste Shredder Material:

|

Plastics

|

Mouldings, Purgings/Lump, Profiles, Films etc.

|

|

|

|

|||

|

Timber/Wood

|

Pallets, Joiners Waste, Green Waste etc.

|

|

|

|

|||

|

Paper & Cardboard

|

Confidential Documents, Production Waste, Packaging Materials etc.

|

|

|

|

|||

|

Copper Cable

|

Household, Telecoms and Industrial Cables including S.W.A

|

|

|

|

|||

|

Aluminum

|

Used Beverage Cans (UBC's), Swarf, Cables etc.

|

|

|

|

|||

|

Textiles

|

Carpet (Rolls & Tiles), Garments etc.

|

|

|

|

|||

|

Security Destruction

|

Counterfeit Items, Faulty Goods, Out of Date Stock etc.

|

|

|

|

|||

|

Foam

|

Production Waste etc.

|

|

|

|

|||

Our advantage:

* It has the characteristics of low speed, high torque and low noise. It is controlled by PLC. It has the functions of starting, stopping, reversing and overloading automatic reversing.

* The motor + reducer drives the cutter shaft to achieve the shearing effect of low speed and high torque.

* Bearing six-fold seal, effective waterproof and dust-proof, prolong the service life of bearings.

* After tool wear, the repair technology of tool coating and welding is adopted to realize the repeated use of the tool, which greatly reduces the maintenance cost of the tool.

* Separate box design, can easily and quickly remove the entire axle (axle, blade, bearing, sealing system)..

* Tools are arranged according to helix to achieve high efficiency cutting.

* Both the inner hole and the spindle face of the cutter are designed in hexagonal form to realize the uniformity of the force exerted on the cutter.

* According to different materials and product shapes to be torn up, different types of cutters can be selected.

* The motor + reducer drives the cutter shaft to achieve the shearing effect of low speed and high torque.

* Bearing six-fold seal, effective waterproof and dust-proof, prolong the service life of bearings.

* After tool wear, the repair technology of tool coating and welding is adopted to realize the repeated use of the tool, which greatly reduces the maintenance cost of the tool.

* Separate box design, can easily and quickly remove the entire axle (axle, blade, bearing, sealing system)..

* Tools are arranged according to helix to achieve high efficiency cutting.

* Both the inner hole and the spindle face of the cutter are designed in hexagonal form to realize the uniformity of the force exerted on the cutter.

* According to different materials and product shapes to be torn up, different types of cutters can be selected.

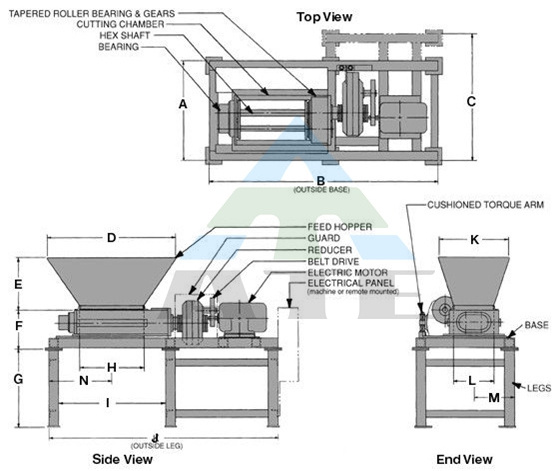

Heavy-load self-aligning bearing

1. We install heavy-load self-aligning bearings on two main shafts.

2. When a blade is impacted by a heavy load,the heavy-load self-aligning bearing produces an immense mechanical action that relieves the impact force.

3. We choose the world's leading bearings of brands as a standard configuration for all Aite shredders.

2. When a blade is impacted by a heavy load,the heavy-load self-aligning bearing produces an immense mechanical action that relieves the impact force.

3. We choose the world's leading bearings of brands as a standard configuration for all Aite shredders.

Detachable cutter

1. Detachable blade design greatly reduces blade replacement time

2. A complete crushing blade comprises of three parts.

3. It is quite easy to replace a worn blade: simply loosen and tighten the bolt.

What types of materials are processed?

It can be used to tear up solid materials such as plastic, rubber, fiber, paper, wood, electrical parts, cables, etc. which are hard to break, such as: nozzle material, rubber head, PET bottle, cardboard, circuit board, wood, plastic barrel, etc. You can select the corresponding model according to the material size and handling capacity. If users need to break especially hard

materials, such as nylon, ABS, PC and other high-strength engineering plastics, they need to explain the situation.

It can be used to tear up solid materials such as plastic, rubber, fiber, paper, wood, electrical parts, cables, etc. which are hard to break, such as: nozzle material, rubber head, PET bottle, cardboard, circuit board, wood, plastic barrel, etc. You can select the corresponding model according to the material size and handling capacity. If users need to break especially hard

materials, such as nylon, ABS, PC and other high-strength engineering plastics, they need to explain the situation.

PRODUCT SPECIFICATIONS

Four shaft shredder(Medium type)

|

Model

|

XD-M900S

|

XD-M900L

|

XD-M1000S

|

XD-Eh1000

|

XD-EM1000XL

|

|

Blade Diameter(mm)

|

Φ290

|

Φ290

|

Φ320

|

Φ320

|

Φ320

|

|

Shaft Speed(rmp)

|

15-25

|

15-25

|

15-25

|

15-25

|

15-25

|

|

Blade Thickness(mm)

|

25

|

25

|

40

|

40

|

40

|

|

Blade Quantity(pcs)

|

32*2

|

40*2

|

25*2

|

32*2

|

32*2

|

|

Shredding Chamber Size(mm)

|

900*800

|

900*1000

|

1000*1000

|

1000*1200

|

1000*1400

|

|

Motor Power(kw)

|

18.5*2

|

18.5*2

|

22*2

|

22*2

|

22*2

|

|

Machine Size(mm)

|

2400*1550*2500

|

2600*1550*2500

|

2900*1700*2800

|

3100*1700*2800

|

3300*1700*2800

|

|

Machine Weight(kg)

|

4700

|

5000

|

6600

|

7100

|

7600

|

Four shaft shredder(Heavy type)

|

Model

|

XD-H900S

|

XD-H900L

|

XD-H1500XL

|

XD-E1600LS

|

XD-E1600L1600L

|

|||||

|

Blade Diameter(mm)

|

Φ430

|

Φ430

|

Φ510

|

Φ510

|

Φ510

|

|||||

|

Shaft Speed(rmp)

|

10-25

|

10-25

|

10-25

|

10-25

|

10-25

|

|||||

|

Blade Thickness(mm)

|

50

|

50

|

50

|

50

|

50

|

|||||

|

Shredding Chamber Size(mm)

|

1300*1200

|

1300*1400

|

1300*1600

|

1300*1600

|

1300*1800

|

|||||

|

Motor Power(kw)

|

30*2+15*2

|

30*2+15*2

|

30*2+15*2

|

45*2+30*2

|

45*2+30*2

|

|||||

|

Machine Size(mm)

|

4100*2000*3100

|

4300*2000*3100

|

4500*2000*3100

|

4800*2300*3600

|

5000*2300*3600

|

|||||

|

Machine Weight(kg)

|

15600

|

16000

|

17000

|

22500

|

23700

|

|||||

|

We can customize the product on your request

|

|

|

|

|

|

|||||

Hot Searches