- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

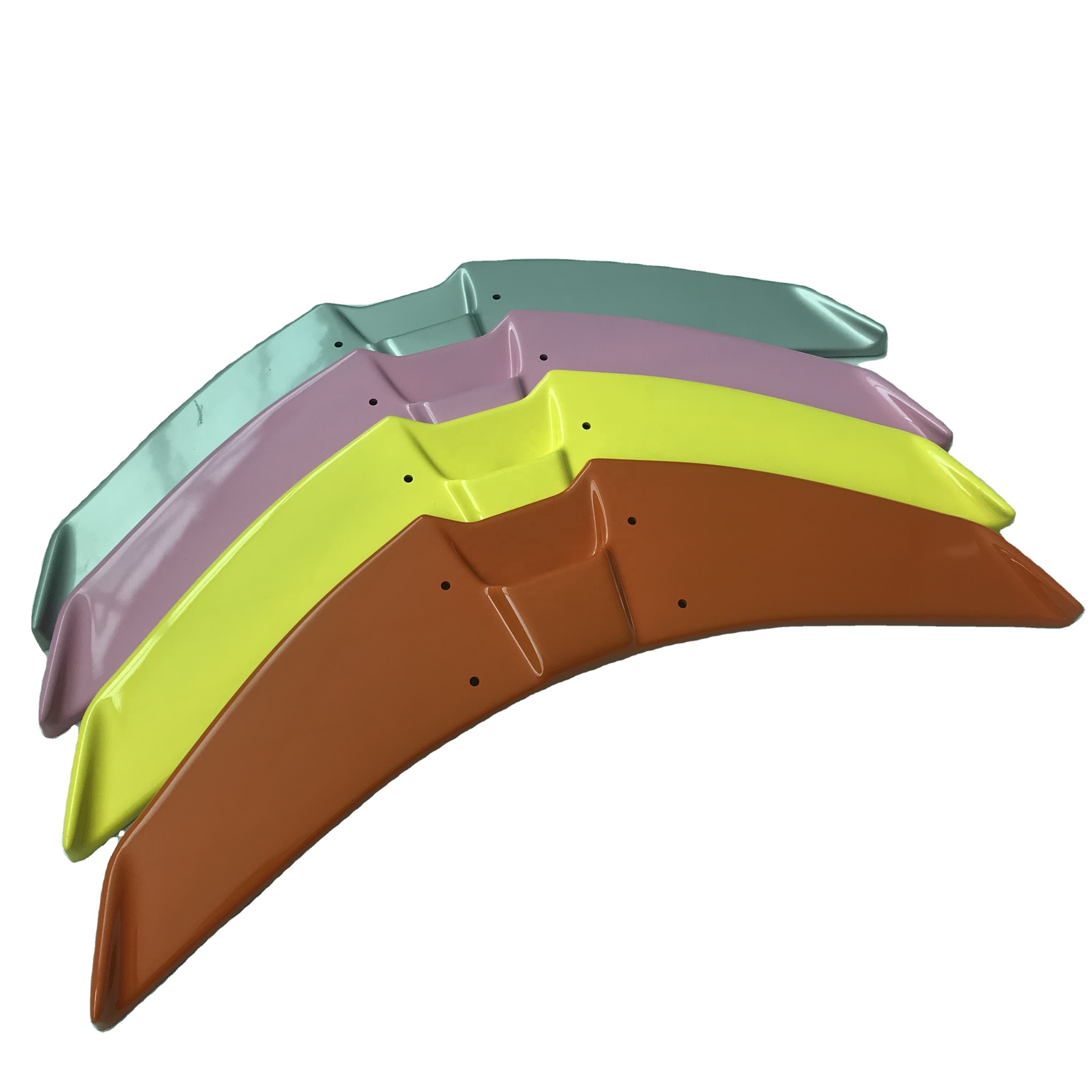

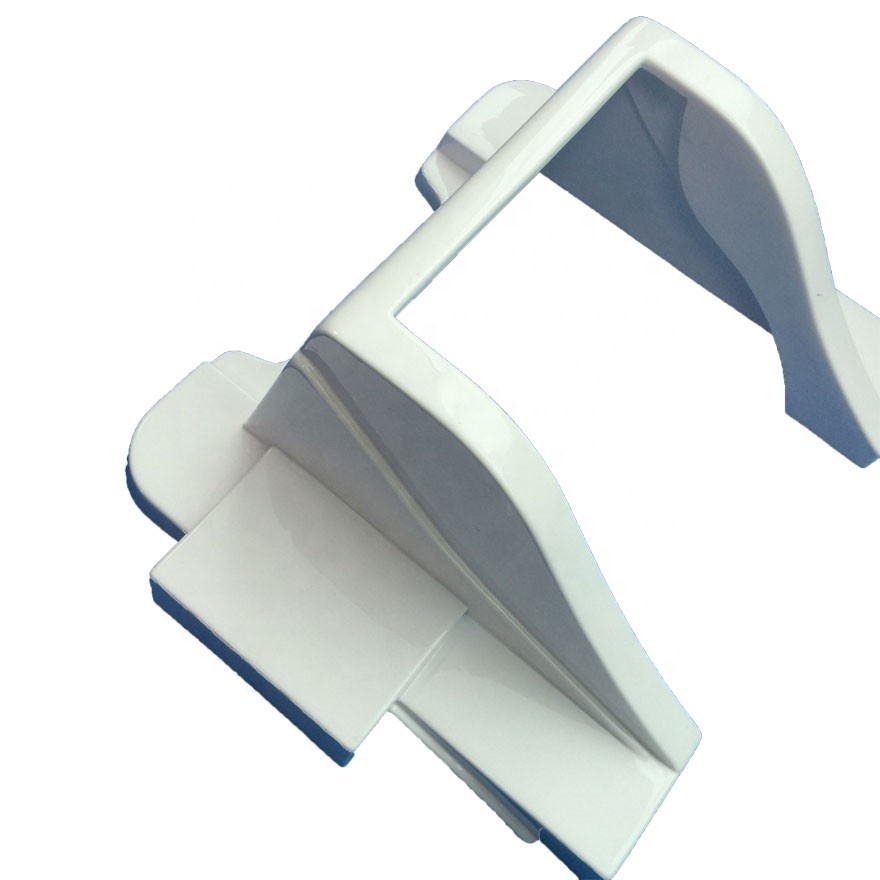

ATV Plastic Body Cover ATV Body Parts Scooter Plastics Parts

-

Material:

-

All kinds of plastc material

-

Process:

-

Vacuum forming

-

Size:

-

Max 4000*2000*1000mm

-

Shape::

-

Customer Requestment

-

Logo::

-

Any logo can be printed

-

Shape:

-

Custom

-

Thickness:

-

1-12mm

-

Color:

-

Any color can be choice

-

Certification:

-

ISO9001:2008

Quick Details

-

Warranty:

-

1year

-

Place of Origin:

-

Guangdong,China

-

Brand Name:

-

Ditai

-

Product name:

-

ATV Plastic Body Cover ATV Body Parts Scooter Plastics Parts

-

Material:

-

All kinds of plastc material

-

Process:

-

Vacuum forming

-

Size:

-

Max 4000*2000*1000mm

-

Shape::

-

Customer Requestment

-

Logo::

-

Any logo can be printed

-

Shape:

-

Custom

-

Thickness:

-

1-12mm

-

Color:

-

Any color can be choice

-

Certification:

-

ISO9001:2008

Product Description

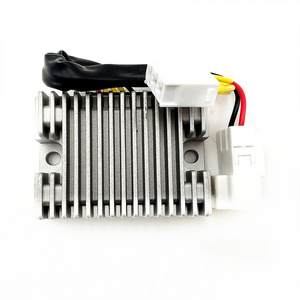

Product Name: OEM Thermoforming Factory Supply Plastic Auto Spare Parts Car Plastic Parts ATV Plastics Parts

|

Key

Words

|

ATV Plastics Parts

|

|

Available Material

|

ABS, PS, HDPE, PC,

PETG, PVC etc

|

|

Max Size

|

4000*2000*1000mm.

|

|

Thickness Range

|

1-12mm

|

|

Color

|

Customized

|

|

Logo

|

Affordable.

|

Material Suggestion For Your Products:

When choosing a plastic, you'll need to consider application. Will your product be used inside our out? Will it be exposed to extreme heat or cold? Does the product need to withstand high impact? Are you looking for something that's fire retardant?

As a general rule of thumb, we work to the following guidelines.

The following chart provides additional information about various plastic materials and their uses.

|

plastic material

|

advantage

|

disadvantage

|

industry example

|

|

PS(Polystyrene)

|

Clear plastic, very moldable, inexpensive, recyclable, high chemical resistance, high electrical resistance, heat distortion ~200°F

|

|

Disposable cups, disposable applications, decorative applications, electrical applications

|

|

HIPS (High Impact Polystyrene)

|

Very moldable, relatively inexpensive

|

Very moldable, relatively inexpensive

|

Picture frames, shower walls, food containers

|

|

ABS (Acrylonitrile Butadiene Styrene)

|

Engineered plastic that can be customized to desired levels of stiffness, hardness, heat deflection, and many other characteristics

|

|

|

|

PVC (PolyvinylChloride)

|

Very high chemical resistance, stain resistant, stiffer than ABS, high room temp. impact strength, natural flame retardant qualities

|

Difficult to process

|

shower surrounds, moldings, kick panels, display cases

|

|

Polycarbonate

|

Extremely high impact resistance, high clarity – good for transparent parts, precision molding, good insulator, high heat distortion point ~270°F

|

Low chemical resistance to certain substances (oil, gasoline, harsh chemicals), can be difficult to process, higher material and processing cost

|

Visors, plastic guards, transportation components (headlights, taillights, instrument panels), appliance drawers, skylights

|

|

Polycarbonate/ABS

|

When compared to true polycarbonate – less expensive, lower heat distortion ~240°F, much easier to process, higher chemical resistance

|

When compared to true polycarbonate – reduced clarity, lower heat distortion ~240°F

|

When compared to true polycarbonate – reduced clarity, lower heat distortion ~240°F

|

|

PETG

(polyethylene- terephthalate) |

Very easy to process, high clarity – good for transparent parts

|

Not UV stable – unsuitable for extended exposure

|

Structural automotive parts, hand tools, industrial components

|

Hot Searches