- Product Details

- {{item.text}}

Quick Details

-

Applicable Industries:

-

Packing Industry

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

PRINTYOUNG

-

Voltage:

-

220 V

-

Dimension(L*W*H):

-

5880 x 2100 x 2350 mm

-

Weight:

-

16000 KG

-

PLC Brand:

-

OTHER

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Driven Type:

-

Electric

-

Application:

-

die cutting

-

Max paper size:

-

1080*780mm

-

Pre-stacking height:

-

1550mm

-

Collection stack height:

-

1400mm

-

Paper board feeding:

-

Automatic

-

Dimension:

-

5880*2100*2350(mm)

-

Certification:

-

CE, CE Certificate

Quick Details

-

Type:

-

Die-cutting Machine

-

Production Capacity:

-

7000 s/h

-

Max. workable width:

-

1100 mm

-

Applicable Industries:

-

Packing Industry

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

PRINTYOUNG

-

Voltage:

-

220 V

-

Dimension(L*W*H):

-

5880 x 2100 x 2350 mm

-

Weight:

-

16000 KG

-

PLC Brand:

-

OTHER

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Driven Type:

-

Electric

-

Application:

-

die cutting

-

Max paper size:

-

1080*780mm

-

Pre-stacking height:

-

1550mm

-

Collection stack height:

-

1400mm

-

Paper board feeding:

-

Automatic

-

Dimension:

-

5880*2100*2350(mm)

-

Certification:

-

CE, CE Certificate

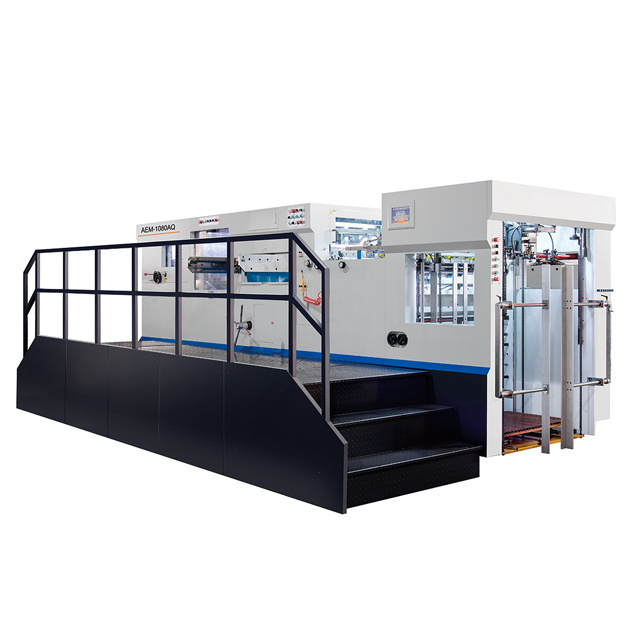

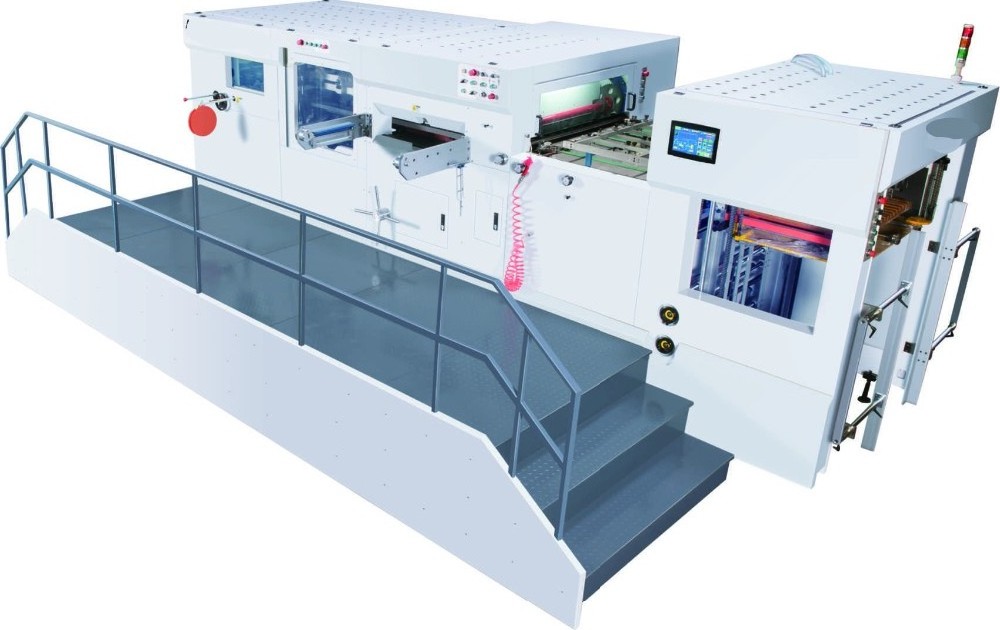

AEM-1080Q Fully Automatic Die Cutting Machine With Stripping

Features

1.The machine made by professional precessing, with scientific structure. Easy to operate, prefesssional safety performance, Iarge cutting pressure to make high benefit.

2.Suitable for papaer board, corrugated board, PP, PVC, concave-convex printing etc. Wide field of application, long service life.

further features

Automatic feeding device: The device use European technology strong suction head. 4 sucktion 5 deliver function, adjustable smooth, stable, according to paper style and different angle of bend to make adjustment for get wild range of application. 2 group of laser control device to avoid the collision, with unstop feeding systerm to improve work efficiency.

Die cutting: The casting made by high strength resin sand process, air clutch to drive the high precision worm and worm wheel to ensure less deformation when get die cutting stress, smooth running in high speed. High speed intermittent device drived Germany chain, aluminum alloy with special process, double location to ensure the precision. The frame, air lock device, turnover device to change the groups(optional) to get more easy for sesond mould change, concave-convex cutting, replace the mould, also save time and cost. Automatic pressure adjustment device(optional) to adjust the pressure more easy and controllable.

Feeding: Adopt synchronous transport, smooth running, feeding shelves with air spring can mke operation more easily. There are push, pull, dual-purpose type side gauge on the both of sides, with adjustable front gauge location device, imported laser location device to make location more precision. Also have empty sheet, skew sheet, double sheet control device to ensure the feeding precision, smooth, reduce the waste of paper, single point clutch function can make feeding and cutting seperation anytime or synchronous combining, it makes operation more easily.

Stripping: The stripping device made with above frame, middle frame, below frame. These 3 linkage frame can transport power easily. can shaft curvilinear motion. it can improve the stability of stripping, with middle line ftame can fast change the mould. The preset shelves(optional) can make Pre typesetting out of machine to reduce the typesetting time. Stripping air stopped device to extend the service life.

Delivery: Adobt mechanical drive brush press paper device, with bidirectional blowing device to deliver paper smoothly. Set the Speed reduction or stop delivery after paper's full, also can choose unstop delivery with vice delivery device. Take sample with air control, make table for any number of piece paper, setting automatic stop after reach setting pieces function.

others: The machines adopts imprted electrical parts, imported bearing. Internal and external librication, internal parts adopts oil circulation system and ecternal parts use PLC automatic contrl oil pump system to keep machine interface is easy for make operation, also have fault display function, can notice the fault with sound and light alarm to ge toubleshooting on time. The flash memory disk(USB) can upgrade system very easily.

Product Show

Main Technical Datas

| Model | Max paper size(mm) | Min paper size(mm) | Max cutting size(mm) | Die frame inner size(mm) | Cutting precision(mm) | Cutting plate size(mm) | Min gripper clamp size(mm) | Max cutting pressure(T) | Max cutting speed(s/h) | Pre-stacking height(mm) |

| AEM-1080Q | 1080×780 | 400×330 | 1075×770 | 1100×790 | ≤ ± 0.1 | 1080×780 | 7 | 300 | 7000 | 1550 |

| Model | Collection stack height(mm) | Application | White board(mm) | Corrugated paper(mm) | Main motor power(kw) | Total power(kw) | Weight(T) | Dimension[L(+pre-stacking)×W(+platform)×H] (mm) |

| AEM-1080Q | 1400 | / | 0.1-2 | <4 | 11 | 17.8 | 16 | 5880(+1650)×2100(+1600)×2350 |

Packaging Type: Export Wooden Case

Why Choose us ?

1 . Profession -- W e have many years folder glue machine experience for South America, Africa and Mid East, etc. Our target is make high quality and resonable price umbrella product for customer.

2. Price -- Because we have factory, so we can provide higher quality products, we can control the cost. As the price here just for reference, If you are interested in our products, please contact us to discuss the specific price.

3 . Service -- We have professional sales system, and any of your inquiry will be treated within 12 hours in a detailed quotation. We are the manufacturer of folder gluer machines, so we can produce any style of folder gluer machine as customer requirement, just give us your specification and pictures or offer us your budget, we can also design for you.

4. Quality -- Straight quality control system in production process, and professional QC in our factory for different customer.

Please Feel Free To Contact Us !