- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

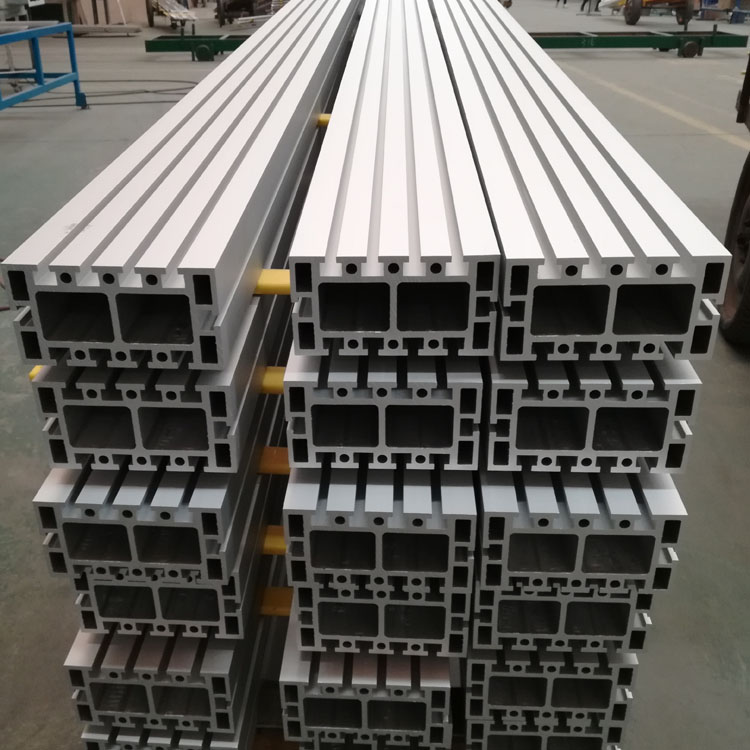

CNC Aviation Aluminum Gantry Beam

-

Brand Name:

-

ZHONGLIAN

-

Surface treatment:

-

Mill Finish

-

Material:

-

Alloy 6063/6061/6082 T5/T6

-

Color:

-

Customized Color

-

Delivery time:

-

15-21 Days

-

MOQ:

-

500KG

-

Service:

-

Custom Aluminum Profiles

-

Deep process:

-

Punching Driling Precison Cutting

-

Size:

-

200*200 Customer's Drawing Required

Quick Details

-

Grade:

-

6000 Series

-

Tolerance:

-

±1%

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

CNC Aviation Aluminum Gantry Beam

-

Brand Name:

-

ZHONGLIAN

-

Surface treatment:

-

Mill Finish

-

Material:

-

Alloy 6063/6061/6082 T5/T6

-

Color:

-

Customized Color

-

Delivery time:

-

15-21 Days

-

MOQ:

-

500KG

-

Service:

-

Custom Aluminum Profiles

-

Deep process:

-

Punching Driling Precison Cutting

-

Size:

-

200*200 Customer's Drawing Required

Company Introduction

100,000 Sqm Factory - At ZHONGLIAN we build

excellence every day!

Guangdong Zhonglian Aluminium Profiles Co., Ltd. is a large-scale comprehensive aluminum profile factory specializing in developing, designing and manufacturing aluminum extrusions. Occupying an area of 100 thousand square meters, we own 23 extrusion lines and a passionate 50 person team professional at foreign trade marketing.

Products Details

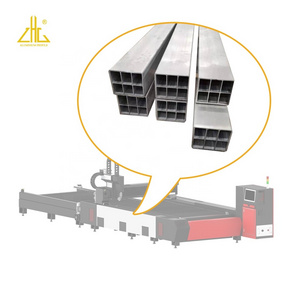

Current market distribution of laser cutting machine beams

The beam of laser cutting machine is an important part of the laser cutting machine. At present, the beam of the laser cutter has the following structural forms:

● Steel plate welded beam. The requirements for welding and heat treatment at various stages are high, the cross-section of the beam is large, and the steel plate used is thick, which results in the beam being too heavy and the dynamic response is poor, which indirectly leads to the increase in the size of the drive motor and increase the cost;

● Cast aluminum alloy beams. This beam is currently used by most laser cutting machine manufacturers. Compared with some other metal beams, the aluminum alloy bracket is lighter in weight, because the density of aluminum is low. At present, the thinnest casting thickness in China is 12mm. It is commonly used in high-power, large-format laser cutting machines to ensure the speed of the laser head and the stability at high speeds;

● Welded aluminum beams. Reasonable cross-section and strength can be obtained, but the welding deformation is large, the manufacturing cycle is long, and it is only used in the case of single piece and small batch production;

● The laser cutting machine extrudes the aluminum profile beam, also known as the aviation industry extruded aluminum profile. The beam adopts a new structure. The beam of a laser cutting machine extruded with aluminum profiled solves the poor mechanical properties of existing beams in production and application, many casting defects, large welding deformation, and long manufacturing cycles. Only used for a series of problems such as single piece and small batch production.

The beam of laser cutting machine is an important part of the laser cutting machine. At present, the beam of the laser cutter has the following structural forms:

● Steel plate welded beam. The requirements for welding and heat treatment at various stages are high, the cross-section of the beam is large, and the steel plate used is thick, which results in the beam being too heavy and the dynamic response is poor, which indirectly leads to the increase in the size of the drive motor and increase the cost;

● Cast aluminum alloy beams. This beam is currently used by most laser cutting machine manufacturers. Compared with some other metal beams, the aluminum alloy bracket is lighter in weight, because the density of aluminum is low. At present, the thinnest casting thickness in China is 12mm. It is commonly used in high-power, large-format laser cutting machines to ensure the speed of the laser head and the stability at high speeds;

● Welded aluminum beams. Reasonable cross-section and strength can be obtained, but the welding deformation is large, the manufacturing cycle is long, and it is only used in the case of single piece and small batch production;

● The laser cutting machine extrudes the aluminum profile beam, also known as the aviation industry extruded aluminum profile. The beam adopts a new structure. The beam of a laser cutting machine extruded with aluminum profiled solves the poor mechanical properties of existing beams in production and application, many casting defects, large welding deformation, and long manufacturing cycles. Only used for a series of problems such as single piece and small batch production.

|

Customized specifications

|

ALUMINIUM TUBES

|

|

|

Material

|

6000 series Aluminium, 6061 or 6063 or 6082 or 7075

|

|

|

Temper

|

T4, T5, T6

|

|

|

Size

|

200*200mm to 300*300mm or Custom

|

|

|

Size / Thickness

|

General profiles thickness from 0.8 to 5.0mm, length from 3m-6m or customized available; Anodize protection film thickness from

8~25 um, powder coating from 40 ~ 120 um. |

|

|

Shape

|

square, round, rectangular, customized

|

|

|

Application

|

CNC Aviation Aluminum Gantry Beam

|

|

|

Surface treatment

|

powder coating, anodized and so on

|

|

|

Colors

|

Ref powder coating color sheet and customized color available

|

|

|

Deep process

|

drilling, milling, cutting, welding, bending, assembling

|

|

|

MOQ

|

3000kgs for each item

|

|

|

Packing Details

|

(1)Inside : packed with plastic protective film to protect each piece

|

|

|

|

(2) Outside: Wrap to be bundles by waterproof craft paper

|

|

|

Delivery time

|

(1)Die Developing and Sample testing: 12-18 days .

|

|

|

|

(2) Mass Production completed: 20-30days after sample is confirmed by Buyer.

|

|

|

FOB Port

|

SHENZHEN / GUANGZHOU / FOSHAN

|

|

|

payment terms

|

T/T 30% for deposit, balance before shipping.

|

|

|

settlement term

|

Charge by final actual weight or by drawing theoretical weight.

|

|

|

Production capacity

|

5000 tons monthly, 60000 tons annually.

|

|

|

Certificate and Standard

|

CQM, SGS, CE, BV, SONCAP / GB, ISO, JIS, AS, NZS, QUALICOAT, QUOLANOD available

|

|

|

Guarantee

|

Surface color can be stable for 10~20 years indoor using.

|

|

Step 1:

Export your design to a CAD file format

The file formats predominantly used in CNC machining are STEP and IGES. These formats are open-source, standardized and can be used across platforms.

For best results:

Export your designs directly from your native CAD software into the STEP file format

Step 2:

Prepare a technical drawing

A technical drawing is not always required for machining parts with CNC. Yet it is recommended to include one in your order

as it has information that is not presented in a STEP file.

Step 3: Get an instant quote & start manufacturing

A technical drawing is required in the following:

/

When your design contain threads

/

When any tolerances are specified

/

When certain surfaces need a different finishing

Recommend Products

Why Choose Us

Contact Us

Hot Searches