- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

NanXiang

-

Product name:

-

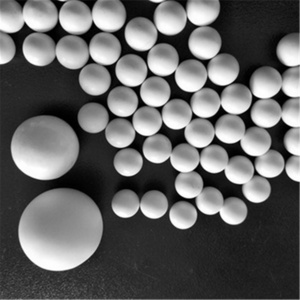

High Alumina Ceramic Grinding Media Balls Alumina Wet Grinding Ball

-

Shape:

-

Ball

-

Raw material:

-

Alumina Powder

-

Size:

-

3mm 6mm 10mm 19mm 25mm 38mm 50mm

-

Keywords:

-

High Alumina Al2O3 Ceramic Grinding Media Balls

-

Working temperature:

-

1000℃

-

MOQ:

-

1 Ton

-

Material Content:

-

99%

-

Package:

-

25kg/Bag or Steel Drum Bags

-

Hardness:

-

9Moh's

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Jiangxi, China

-

Model Number:

-

NX-LX0817

-

Brand Name:

-

NanXiang

-

Product name:

-

High Alumina Ceramic Grinding Media Balls Alumina Wet Grinding Ball

-

Shape:

-

Ball

-

Raw material:

-

Alumina Powder

-

Size:

-

3mm 6mm 10mm 19mm 25mm 38mm 50mm

-

Keywords:

-

High Alumina Al2O3 Ceramic Grinding Media Balls

-

Working temperature:

-

1000℃

-

MOQ:

-

1 Ton

-

Material Content:

-

99%

-

Package:

-

25kg/Bag or Steel Drum Bags

-

Hardness:

-

9Moh's

Products Description

Grinding Balls

are suitable for grinding medium used in ball grinding machines.

The alumina balls’ wear-resistance is higher than the common alumina balls’. When it is working, the ball won’t pollute the

grinding materials, so it can keep the purity and improve the stability of grinded materials especially the ceramic glaze.

The high density, high hardness and the high grinding characters save the grinding time, enlarge the smashing room. So it can improve the grinding efficiency.

The alumina balls’ wear-resistance is higher than the common alumina balls’. When it is working, the ball won’t pollute the

grinding materials, so it can keep the purity and improve the stability of grinded materials especially the ceramic glaze.

The high density, high hardness and the high grinding characters save the grinding time, enlarge the smashing room. So it can improve the grinding efficiency.

Typical Application:

a) It's a very excellent and ideal product for high temperature and steam applications, such as secondary reformers in ammonia processing, where leached silica will coat downstream equipment or foul the catalyst bed.

b) It's suitable for applications in olefin processes, such as ethylene dryers, where there's the polymerization problem.

a) It's a very excellent and ideal product for high temperature and steam applications, such as secondary reformers in ammonia processing, where leached silica will coat downstream equipment or foul the catalyst bed.

b) It's suitable for applications in olefin processes, such as ethylene dryers, where there's the polymerization problem.

Alumina ceramic chemical packing balls

are widely used as bottom filler materials in hydrocracking device, refining device, catalytic reforming unit, isomerization device, demethylation unit of petrochemical plant, chemical fibre factory, fertilizer factory, alkylbenzene factory, aromatic hydrocarbon factory, ethylene plant, natural gas plant etc. With functions as covering and supporting media for catalyst in reactors and packing for towers. The main role of inert alumina ball is increasing the distribution of liquid and gas, holding and protecting the activated catalyst with low strength.

Chemical composition for 23% Inert Alumina Ceramic Ball:

|

Al2O3 + SiO2

|

Al2O3

|

SiO2

|

Fe2O3

|

CaO

|

MgO

|

K2O + Na2O

|

Other

|

|

> 92%

|

23-26%

|

68-72%

|

0.4-0.8%

|

0.6-0.9%

|

0.6-1.2%

|

< 3.5%

|

< 1%

|

Packing and mechanical properties of Inert Ceramic Balls:

|

Normal size

(inch – mm)

|

Packing Density

|

|

Specific Surface

|

|

Void Fraction, %

|

Compressive Strength per ball, kg

|

||

|

|

kg/m3

|

lb/ft3

|

m2/m3

|

ft2/ft3

|

44

|

|

||

|

1/8" – 3mm

|

1400

|

88

|

720

|

220

|

44

|

30

|

||

|

1/4" – 6mm

|

1400

|

88

|

520

|

158

|

44

|

50

|

||

|

3/8" – 9mm

|

1400

|

88

|

360

|

110

|

44

|

120

|

||

|

1/2" – 13mm

|

1350

|

84

|

275

|

84

|

45

|

180

|

||

|

3/4" – 19mm

|

1350

|

84

|

190

|

58

|

45

|

300

|

||

|

1" – 25mm

|

1350

|

84

|

144

|

44

|

45

|

400

|

||

|

1¼" – 32mm

|

1350

|

84

|

120

|

37

|

45

|

520

|

||

|

1½" – 38mm

|

1350

|

84

|

100

|

30

|

45

|

600

|

||

|

2" – 50mm

|

1350

|

84

|

75

|

23

|

45

|

720

|

||

17-19% Ceramic Ball Kinds of Sizes

68% 75% 80% 92% Inert Al2O3 Kinds of Sizes

92% 95% 99% Al2O3 Inert Alumina Ceramic Ball

Details Images

Our Factory&Workshop

Product Packaging

Our Team

FAQ

Contact Us

Hot Searches