- Product Details

- {{item.text}}

Quick Details

-

Heating Power (kW):

-

120 kW

-

Production Speed(times/h):

-

60

-

Power Supply:

-

DC

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Samstech

-

Voltage:

-

90V-380V/50HZ

-

Dimension(L*W*H):

-

1550*1150*1520mm

-

Weight (T):

-

3.5 T

-

Product name:

-

Plastic Thermoforming Blister Forming Machine

-

Qty of Stations:

-

1

-

Sheet Material:

-

PP,PS,PET,PVC,HIPS,EPS,OPS,ABS

-

Max.Forming Area:

-

800*600mm

-

Max.Forming Depth:

-

750 mm

-

Max.Forming Height:

-

10 mm

-

Max.Sheet Width:

-

800mm

-

Sheet Thickness:

-

1-12mm

-

Max Height Of Mold:

-

300mm

-

Work efficiency:

-

2-3 min/ mold

Quick Details

-

Max.Forming Height(mm):

-

750 mm

-

Forming Width (mm):

-

800 mm

-

Forming Length (mm):

-

2500 mm

-

Heating Power (kW):

-

120 kW

-

Production Speed(times/h):

-

60

-

Power Supply:

-

DC

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Samstech

-

Voltage:

-

90V-380V/50HZ

-

Dimension(L*W*H):

-

1550*1150*1520mm

-

Weight (T):

-

3.5 T

-

Product name:

-

Plastic Thermoforming Blister Forming Machine

-

Qty of Stations:

-

1

-

Sheet Material:

-

PP,PS,PET,PVC,HIPS,EPS,OPS,ABS

-

Max.Forming Area:

-

800*600mm

-

Max.Forming Depth:

-

750 mm

-

Max.Forming Height:

-

10 mm

-

Max.Sheet Width:

-

800mm

-

Sheet Thickness:

-

1-12mm

-

Max Height Of Mold:

-

300mm

-

Work efficiency:

-

2-3 min/ mold

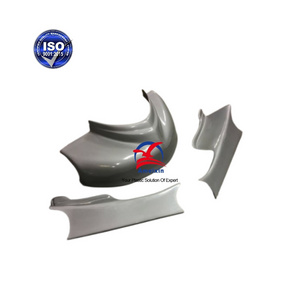

Product Overview

The automatic thick sheet plastic vacuum forming machine is widely applied in 1-12mm of ABS, PP, PE, PS, PC, PVC, EPS, HIPS,HDPE, PMMA, PET, PETG plastic sheet vacuum formed products such, it is an ideal vacuum forming machine for automobile parts likecar foot mat, car trunk mat, car bumper, light box, plastic board, plastic containers, plastic pallet, plastic helmet, plastic covers, bathtub, fruit tray, suitcase, apparatus shell, instrument panel, refrigerator inner liners, etc.Can replace injection molding and fiberglass products and save energy and mold costs.

FEATURES AT A GLANCE

Main Features:

One single heating oven with two work station, JJS2412 is a new price-performance ratio for automatic production class machines The reform can save electric power effectively, shorten reclaiming time of invest, reduce operating and equipment cost greatly and then develop enterprises frugally.

1) Digital timer with audible warning helps achieve consistent cycle times.

2)According to consumer's need,PLC control available.

3) programme memory to recall heater profile and timing settings for each project.(PLC type)

5) 25pcs Solid state voltage regulators, control heating boards simple and visualized.

6) Large-scale cooling fan which can cool the products quickly.

7)Cooling system which suit for thick material.(optional)

8) Manual and Semi-auto style.

One single heating oven with two work station, JJS2412 is a new price-performance ratio for automatic production class machines The reform can save electric power effectively, shorten reclaiming time of invest, reduce operating and equipment cost greatly and then develop enterprises frugally.

1) Digital timer with audible warning helps achieve consistent cycle times.

2)According to consumer's need,PLC control available.

3) programme memory to recall heater profile and timing settings for each project.(PLC type)

4) 30pcs ceramic infrared heating boards which can be controlled separately, suit for different size or different thickness

material.

material.

5) 25pcs Solid state voltage regulators, control heating boards simple and visualized.

6) Large-scale cooling fan which can cool the products quickly.

7)Cooling system which suit for thick material.(optional)

8) Manual and Semi-auto style.

Application:

Suitable for thick sheet (thickness more than 2mm) product, like auto interior decoration, light box advertisement, refrigerator liner, trunk, tray, stationery, hardware, etc.

Product Sample 1

Product Sample 2

Product Sample 3

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

Power Supply

|

380V/50Hz

|

|

1

|

Forming Area (mm)

|

2500*1000mm (Adjustable)

|

Vacuum Pump Capacity

|

100 m³/min

|

|

2

|

Forming Width (mm)

|

800mm

(Adjustable)

|

Heaters

|

heating tube

|

|

3

|

Forming Length (mm)

|

750 mm

(Adjustable)

|

Air Pressure

|

0.6-0.8Mpa

|

|

4

|

Material Thickness (mm)

|

1-12mm

|

Water Chiller

|

5HP

|

|

5

|

Material

|

PVC,PET,PP,PS,HIPS,ABS,ACRYLIC

|

Safety protection equipment

|

infrared ray

|

|

6

|

Material type

|

Roll

|

Material Loading

|

Manual

|

|

7

|

Heater(pcs)

|

60 pcs

|

Up Heating tube

|

236Pcs

|

|

8

|

Total Installed Powe(Kw)

|

120KW

|

Down Heating tube

|

258pcs

|

PRODUCT CONFIGURATION

Heating

Moulding

Finishing

Machine description:

(1)This Machine: Single Station Thick Sheet Vacuum Forming Machine and was specially designed according to your requested Sizes, the model is HW-15000*2000. It has the character of reasonable structure and easy operation, and is suitable for the Vacuum Forming of big sizes products. High definition Touch Screen, precise temperature control system, the whole system realize human interface.

(2)Havey Gauge thermoforming materials :Custom thermoformed parts from plastics such as ABS, acrylic/PVC, HIPS, HDPE, LDPE, PP, PETG, and polycarbonate

(3)Plastic Thermoforming VS Injection Molding : We provides lower tooling cost ans shorter lead time than injection molding. In addition to machined and cast aluminum,thermoforming tools can be made of wood,epoxy , and other low-cost materials. Tool modifications are cost-effective ,and on -the-fly changes support prototyping,short runs,and medium-volume production.

(4)Process Flow: Manual (Automatic)Feeding - Pressing Frame come down- Double Heating Furnace Forward(Automatic) — Sag Prevent (Automatic)-- Heating Furnace Draw back(Automatic)-- Bubble - blowing(Automatic )— Moulds Rise(same time when Bubble-blowing or postponed ) (Automatic)— Vacuum Forming(Automatic)— Cooling(connected with cooling air and Spraying)(Automatic)— Counter Blow Demould Automatic)— Mould Drop(Automatic)— Pressing Frame Rise— Manual (Automatic)pickup

(1)This Machine: Single Station Thick Sheet Vacuum Forming Machine and was specially designed according to your requested Sizes, the model is HW-15000*2000. It has the character of reasonable structure and easy operation, and is suitable for the Vacuum Forming of big sizes products. High definition Touch Screen, precise temperature control system, the whole system realize human interface.

(2)Havey Gauge thermoforming materials :Custom thermoformed parts from plastics such as ABS, acrylic/PVC, HIPS, HDPE, LDPE, PP, PETG, and polycarbonate

(3)Plastic Thermoforming VS Injection Molding : We provides lower tooling cost ans shorter lead time than injection molding. In addition to machined and cast aluminum,thermoforming tools can be made of wood,epoxy , and other low-cost materials. Tool modifications are cost-effective ,and on -the-fly changes support prototyping,short runs,and medium-volume production.

(4)Process Flow: Manual (Automatic)Feeding - Pressing Frame come down- Double Heating Furnace Forward(Automatic) — Sag Prevent (Automatic)-- Heating Furnace Draw back(Automatic)-- Bubble - blowing(Automatic )— Moulds Rise(same time when Bubble-blowing or postponed ) (Automatic)— Vacuum Forming(Automatic)— Cooling(connected with cooling air and Spraying)(Automatic)— Counter Blow Demould Automatic)— Mould Drop(Automatic)— Pressing Frame Rise— Manual (Automatic)pickup

SALES AND SERVICE NETWORK

SIMILAR PRODUCTS

FAQ

Q1: Are you a factory or trading company

A1: We are a factory, we can guarantee our price is first-hand, very cheap and competitive.

Q2: How does your factory do regarding quality control?

A2: All the products will be 100% checked before the shipment.

Q3: What is the price of shipping?

A3: Depending upon the port of delivery, prices varies.

A1: We are a factory, we can guarantee our price is first-hand, very cheap and competitive.

Q2: How does your factory do regarding quality control?

A2: All the products will be 100% checked before the shipment.

Q3: What is the price of shipping?

A3: Depending upon the port of delivery, prices varies.

A4: How many days will you finish installing ?

Q4: We will finish installation and training within 15 days.

A5: How long is your machine's warranty period?

Q5: All our machine have one year guarantee, starting from finished installation.

A6: How could we do if the parts broken within warranty?

Q6: Free replacement parts will be sent during the warranty date.

Q4: We will finish installation and training within 15 days.

A5: How long is your machine's warranty period?

Q5: All our machine have one year guarantee, starting from finished installation.

A6: How could we do if the parts broken within warranty?

Q6: Free replacement parts will be sent during the warranty date.

High End Customization ABS Car Bumper Thermoforming 3D Body Kit Vacuum Forming Machine

Kindly contact us for more details. Email:samstech@163.com

We are one of the best Acrylic signage vacuum forming machine ,refrigerator inner/liner making machine ,car mat making machine,luggage vacuum forming machine, car bumper vacuum forming machine, bathtub making machine,semi-automatic vacuum forming machine, industrial super large clamshell vacuum former manufacturers in China. 7*24*365 Services available.

Hot Searches