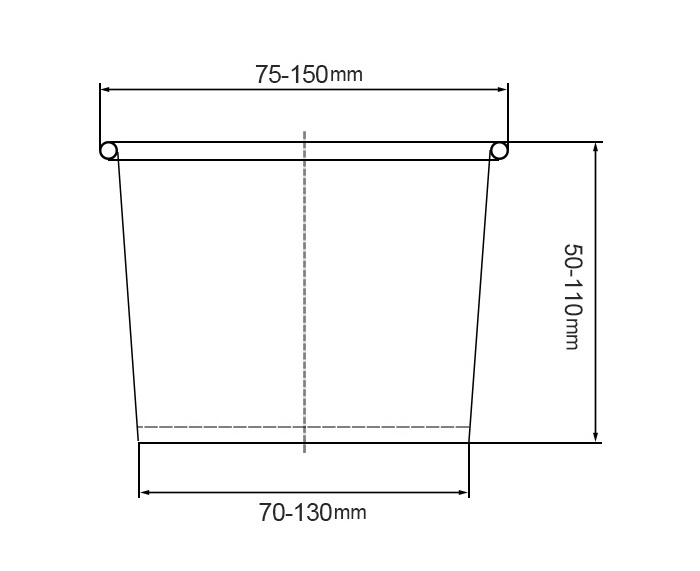

PLC control system speed is 65-75 pcs each min . Cup size range is from 360-1000ML . it adopts the open cam mechanism, gear

transmission, and longitudinal axis structure. The automatic oil lubrication system guarantees all mechanical parts to work more

smoothly . machine is equipped with failure sensor detecting system to detect abnormal work, and realizes automatic shutdown to

protect the various parts of the machine from collision, and improves the stability and life of the machine. It can finish the whole process including paper feeding, side sealing , cup bottom punching & feeding, heating , knurling, cup-top curling ,cup

stacking. It is the best choice for making paper bowl .

transmission, and longitudinal axis structure. The automatic oil lubrication system guarantees all mechanical parts to work more

smoothly . machine is equipped with failure sensor detecting system to detect abnormal work, and realizes automatic shutdown to

protect the various parts of the machine from collision, and improves the stability and life of the machine. It can finish the whole process including paper feeding, side sealing , cup bottom punching & feeding, heating , knurling, cup-top curling ,cup

stacking. It is the best choice for making paper bowl .