- Product Details

- {{item.text}}

Quick Details

-

Use:

-

PCB/BGA/LED all SMD soldering

-

Voltage:

-

220V/110V, AC220V/380V, 50HZ

-

Dimensions:

-

150X90X65CM

-

Rated Duty Cycle:

-

100%

-

Rated Capacity:

-

4500w

-

Current:

-

20A

-

Weight (KG):

-

98 KG

-

Heating Zone:

-

Upper 3 / down 2

-

Soldering Area:

-

300*960 mm / 11.8 x 37.8 in

-

Speed of Conveyor Belt:

-

0-290mm/min

-

Rated Power:

-

4.5KW

-

Heating Up Time:

-

Around 10mins

-

Temperature Control Range:

-

Room temperature - 350 ℃

-

Temperature Control Accuracy:

-

± 1℃

-

L*W*H(mm):

-

1500*900*650MM

-

The operation direction:

-

left to right

Quick Details

-

Marketing Type:

-

Hot Product 2022

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HECAN

-

Use:

-

PCB/BGA/LED all SMD soldering

-

Voltage:

-

220V/110V, AC220V/380V, 50HZ

-

Dimensions:

-

150X90X65CM

-

Rated Duty Cycle:

-

100%

-

Rated Capacity:

-

4500w

-

Current:

-

20A

-

Weight (KG):

-

98 KG

-

Heating Zone:

-

Upper 3 / down 2

-

Soldering Area:

-

300*960 mm / 11.8 x 37.8 in

-

Speed of Conveyor Belt:

-

0-290mm/min

-

Rated Power:

-

4.5KW

-

Heating Up Time:

-

Around 10mins

-

Temperature Control Range:

-

Room temperature - 350 ℃

-

Temperature Control Accuracy:

-

± 1℃

-

L*W*H(mm):

-

1500*900*650MM

-

The operation direction:

-

left to right

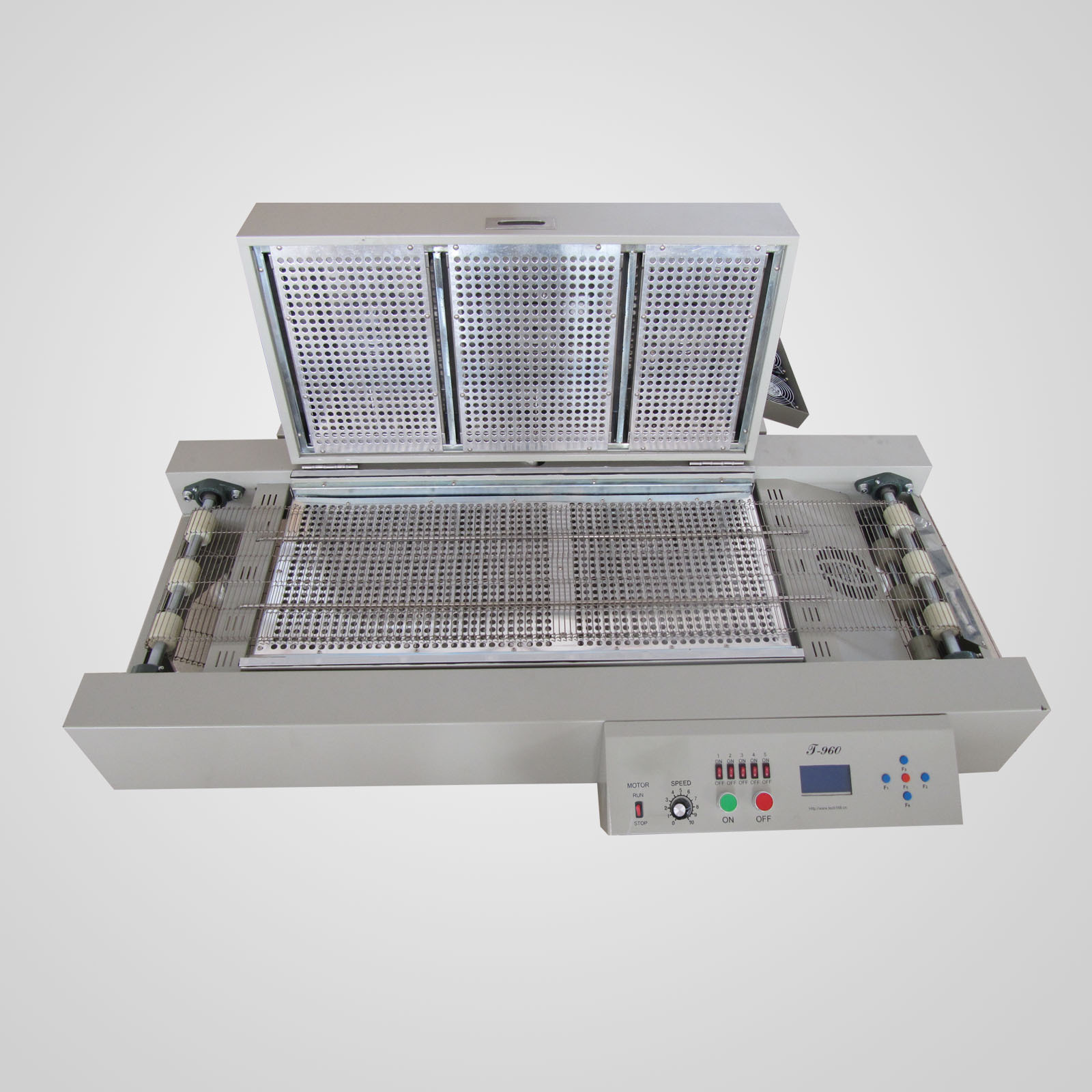

Infrared And Hot Air Benchtop

Conveyor Reflow Oven

Welding Machine T-960W Series

for LED PCB Soldering

Conveyor Reflow Oven

Welding Machine T-960W Series

for LED PCB Soldering

Features

1.This machine selects

Infrared and hot air heating technology

controlling,equipped with special designed wind wheel, so

the speed is stable and the temperature is uniform

, especially suits for

uninterrupted

soldering the LED and BGA components.

2.This machine is equipped with the

crawler-type conveyor

and

5 temperature zones

heating systems.Each temperature zone uses

independent PID controlling

and

up-down heating type

.can make the inside temperature more accurate and well-proportioned. Takes about 15 minutes can let it heat up to the working temperature from the room temperature.

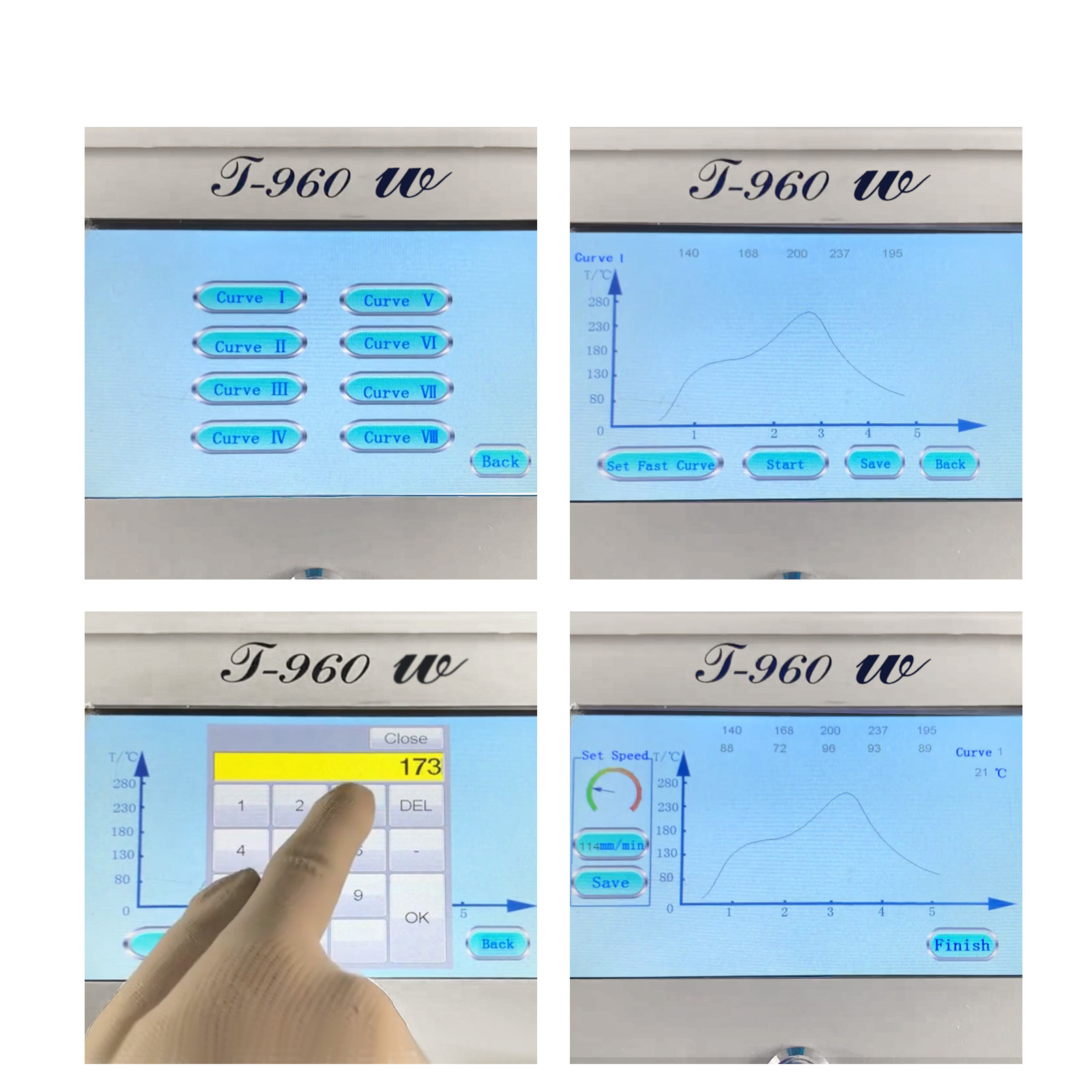

3.Intelligent temperature curve heating type, oversized capacity curve selection. The machine has

8 temperature curves

can satisfy various welding technological requirements.

4. By using programmable technology,presetting the temperature curve memory storage function,can complete the whole welding process automatically .

5. Adopts the

thermocouple temperature measurement

and adds the

compensation circuit

makes the temperature measurement more accurate, the curve more perfect.

6.Using PID intelligent temperature control technology,makes the temperature control more accurate. Adopts the imported large current solid-state relays can effectively avoid the lc or circuit boards being damaged due to the rapid or uninterrupted warming up. Which makes the whole welding process more scientific.

The machine is very easy to operate, with 8 curves in memory, which can satisfy various soldering technological requirments.At the same time,you can change the curves data according to your need.

T960/T960E/T960w How to select curve

Wave 1/2: less lead paste, like 85Sn/15Pb 70Sn/30Pb

Wave 3/4: more lead paste, like 63Sn/37Pb 60Sn/40Pb.

Wave 5/6: high-melting-point lead-free paste, like Sn/Ag3.5;Sn/Cu.75 Sn/Ag4.0/Cu.5; Sn95.5/Ag3.8/Cu0.7

Wave 7/8 : lead-free solder in melting point, like Sn/Ag2.5/Cu.8/Sb.5;Sn/Bi3.0/Ag3.0

Wave 3/4: more lead paste, like 63Sn/37Pb 60Sn/40Pb.

Wave 5/6: high-melting-point lead-free paste, like Sn/Ag3.5;Sn/Cu.75 Sn/Ag4.0/Cu.5; Sn95.5/Ag3.8/Cu0.7

Wave 7/8 : lead-free solder in melting point, like Sn/Ag2.5/Cu.8/Sb.5;Sn/Bi3.0/Ag3.0

|

Model

|

Soldering width

|

Power

|

Temp range

|

Heating zone

|

Dimensions

|

|

T-961

|

230mm

|

3.5KW

|

RT-300℃

|

upper3/down3

|

1000x466x445mm

|

|

T-960

|

300mm

|

4.5KW

|

RT-300℃

|

upper3/down2

|

1450x630x470mm

|

|

T-960E

|

300mm

|

4.5KW

|

RT-350℃

|

upper3/down2

|

1200x630x470mm

|

|

T-960W

|

300mm

|

4.5KW

|

RT-350℃

|

upper3/down2

|

1450x630x470mm

|

Specifications

·

Model: T-960W

· Heating Zone: upper 3 / down 2

· Soldering Area: 300 x 960 mm / 11.8 x 37.8 in.

· Voltage: 220V, 50HZ

· Length of Heating Zone: 960 mm / 37.8 in.

· Max Width of PCB Board: 300 mm / 11.8 in.

· Rated Power: 4.5KW

· Speed of Conveyor Belt: 0-290mm/min

· Heating Up Time: 0-10 mins

· Temperature Control Range: Room temperature - 350 ℃ / 572 ℉

· Temperature Control Accuracy: ± 1℃

· Temperature Distribution Deviation: ± 2℃

· Heating Zone: upper 3 / down 2

· Soldering Area: 300 x 960 mm / 11.8 x 37.8 in.

· Voltage: 220V, 50HZ

· Length of Heating Zone: 960 mm / 37.8 in.

· Max Width of PCB Board: 300 mm / 11.8 in.

· Rated Power: 4.5KW

· Speed of Conveyor Belt: 0-290mm/min

· Heating Up Time: 0-10 mins

· Temperature Control Range: Room temperature - 350 ℃ / 572 ℉

· Temperature Control Accuracy: ± 1℃

· Temperature Distribution Deviation: ± 2℃

·

Heating Mode:

Infrared & Hot Air

·

Temp Cantrol:PID&SSR

·

Direction:

left-right

·

Cooling zone:1

·

L*W*H (mm):

1500*900*650mm

·

Machine Weight:98kg

·

Gross Weight:130kg

Intelligent Heating

PID temperature control, fast infrared radiation, and smooth wind circulation are three key elements of the heating system. The non-contact output of imported high-current solid-state relays can effectively avoid damage to IC or circuit boards, making the entire welding process more scientific and safe.

Eight Temperature Waves

This SMD reflow oven can provide eight kinds of stored temperature parameter waves as options to meet the requirements of various welding processes, and it has mobile heating and cooling functions. Besides, the entire welding process is auto-completed after you preset the wave. So you can say it is easy to use.

Clear Operation Panel

The succinct operation panel provides a user-friendly operation interface. A few control buttons and the LCD screen on the panel allow you to adjust and monitor every data such as speed, time, and temperature. There is no need to connect with the PC, and you can watch the whole repairing process very clearly.

Efficient Cooling Fan

The high-efficiency cooling fan equipped with this machine is to ensure the rapid cooling of PCB boards. It makes them maintain the low temperatures required when PCB board release. Consequently, the process can be completed efficiently and securely.

Large Working Area

An extensive working area of 300 x 960 mm allows the machine to work under different working conditions. The application range is broadened drastically thanks to that. It will definitely be an economic investment for you to make.

Real shot

Packing

FAQ

Q: How is the training?

A: After buying our machines, your engineers can go to our company or it is so easy to operate the machine according the training video and user manual, the user manual will come with the machine together.

Q:Is it hard to use these machines?

A: No, not hard at all For our previous clients, just about 2 days for learning operation

Q:Are machines can meet software update?

Q: How is the training?

A: After buying our machines, your engineers can go to our company or it is so easy to operate the machine according the training video and user manual, the user manual will come with the machine together.

Q:Is it hard to use these machines?

A: No, not hard at all For our previous clients, just about 2 days for learning operation

Q:Are machines can meet software update?

A:YES, we will update machine and will send you at first time

Q:Do you have any operation videos to watch?

A:We provide customers with special operation videos. If you don't understand anything, you can contact us and will arrange engineers to shoot the specified videos.

Q: What kind of maintenance is needed?

A: Add lubricating oil to the guide rail, let the water drain away which from the oil-water separator, and clean the nozzle (we will support this oil)

Service

If you wanna know more, feel free to contact me directly

Mail/Skype:smtmachines@hcpnp.com

Tel/Wechat/WhatsApp:+8618367786556/+8615858886852

Q: What kind of maintenance is needed?

A: Add lubricating oil to the guide rail, let the water drain away which from the oil-water separator, and clean the nozzle (we will support this oil)

Service

If you wanna know more, feel free to contact me directly

Mail/Skype:smtmachines@hcpnp.com

Tel/Wechat/WhatsApp:+8618367786556/+8615858886852

Hot Searches