- Product Details

- {{item.text}}

Quick Details

-

Ceramic coating:

-

YES

-

Nano coating:

-

YES

-

Automotive paint:

-

YES

-

Nano glass coating:

-

YES

-

Hydrophobic coating:

-

YES

-

Glass liquid coating:

-

YES

-

Boat Paint:

-

YES

-

Building Coating:

-

YES

-

Self clean coating:

-

YES

Quick Details

-

CAS No.:

-

3402.90.00.00-9

-

Place of Origin:

-

Taiwan, China

-

Nano ceramic coating:

-

YES

-

Ceramic coating:

-

YES

-

Nano coating:

-

YES

-

Automotive paint:

-

YES

-

Nano glass coating:

-

YES

-

Hydrophobic coating:

-

YES

-

Glass liquid coating:

-

YES

-

Boat Paint:

-

YES

-

Building Coating:

-

YES

-

Self clean coating:

-

YES

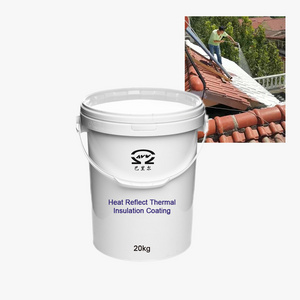

transparent heat insulation glass coating/nano technology/Manufacturer/paint

The object surface is protected through a coating, which is based on ceramic molecular net. Every object surface sealed this way stays clean a much longer period of time and can be cleaned much easier and quicker.

Product Characteristics:

- Strong protection as a result of it's ceramic molecularnet.

- Up to 6 months protection.

- Repelwater–hydrophobic effect that keeps your windows and windshield clear, Even in thunderstorms.

- Surface be comes easy to clean.

- Excellent resistance to weather,UV & temperature.

- Transparent finishing

An original design manufacturer (ODM) is a company which designs and manufactures a product which is specified and eventually branded by another firm for sale. Such companies allow the brand firm to produce (either as a supplement or solely) without having to engage in the organization or running of a factory. ODMs have grown in size in recent years and many are now sufficient in size to handle production for multiple clients, often providing a large portion of overall production. A primary attribute of this business model is that the ODM owns and/or designs in-house the products that are branded by the buying firm. This is in contrast to a contract manufacturer (CM).

Since inception, we have established a large network of manufacturers that can fulfill virtually any product in any industry. Our local office in the United States and world everywhere has been designed to coordinate quick quotes, provide constant updates, and track all data needed to communicate with and expedite all client orders ensuring a smooth transition from placement of orders to delivery, while avoiding the inconvenience and complexities for our customers of dealing directly with factories overseas.

|

|

Permanent |

Semi-Permanent |

||

|

Solvent Base |

Solvent Base |

|||

|

Natural Cure |

Surface Dry |

25°C,1-2hours |

25°C, 8hours |

|

|

Full Dry |

25°C,3-5hours |

25°C,3-5hours |

||

|

Thermal Cure (OVEN) |

130°C,30 minutes |

130°C,30 minutes |

||

|

200°C,10 minutes |

200°C,10 minutes |

|||

|

Application |

Wiping |

X |

V |

|

|

Brushing |

V |

V |

||

|

Dipping |

V (Clean Room Required) |

V (Clean Room Required) |

||

|

Spraying |

V (Clean Room Required) |

V (Clean Room Required) |

||

|

Pencil Hardness |

UP to 9H |

Below to 9H |

||

|

Thickness of coating |

UP to 30 micron |

UP to 20 Micron |

||

|

Viscosity (#2 Zahn Cup, Cup Measurement) |

14 seconds |

10 Seconds |

||

|

Applicator Materials |

*Metal *Wood/Stone/Ceramic *Plastic/Rubber *Glass *Leather/Fabric/Textile * NON-Absorbent Leather |

*Metal *Wood/Stone/Ceramic *Plastic/Rubber *Glass *Leather/Fabric/Textile * NON-Absorbent Leather |

||

|

Standard Consumption By Spraying on non-porous surface |

900 cm2/ml |

900 cm2/ml |

||