- Product Details

- {{item.text}}

Quick Details

-

Standard or Nonstandard:

-

Standard

-

Website:

-

www.supseals.com

-

Seal face:

-

Carbon, Silicon Carbide

-

Elastomer:

-

Nitrile, Viiton, EPDM

-

Metal part:

-

SS304, SS316

-

Pressure::

-

Up to 12 bar (174 PSI),

-

Sliding velocity::

-

vg = 10 m/s (2000 fpm)

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

JR

-

Model Number:

-

JR MG13

-

Standard or Nonstandard:

-

Standard

-

Website:

-

www.supseals.com

-

Seal face:

-

Carbon, Silicon Carbide

-

Elastomer:

-

Nitrile, Viiton, EPDM

-

Metal part:

-

SS304, SS316

-

Pressure::

-

Up to 12 bar (174 PSI),

-

Sliding velocity::

-

vg = 10 m/s (2000 fpm)

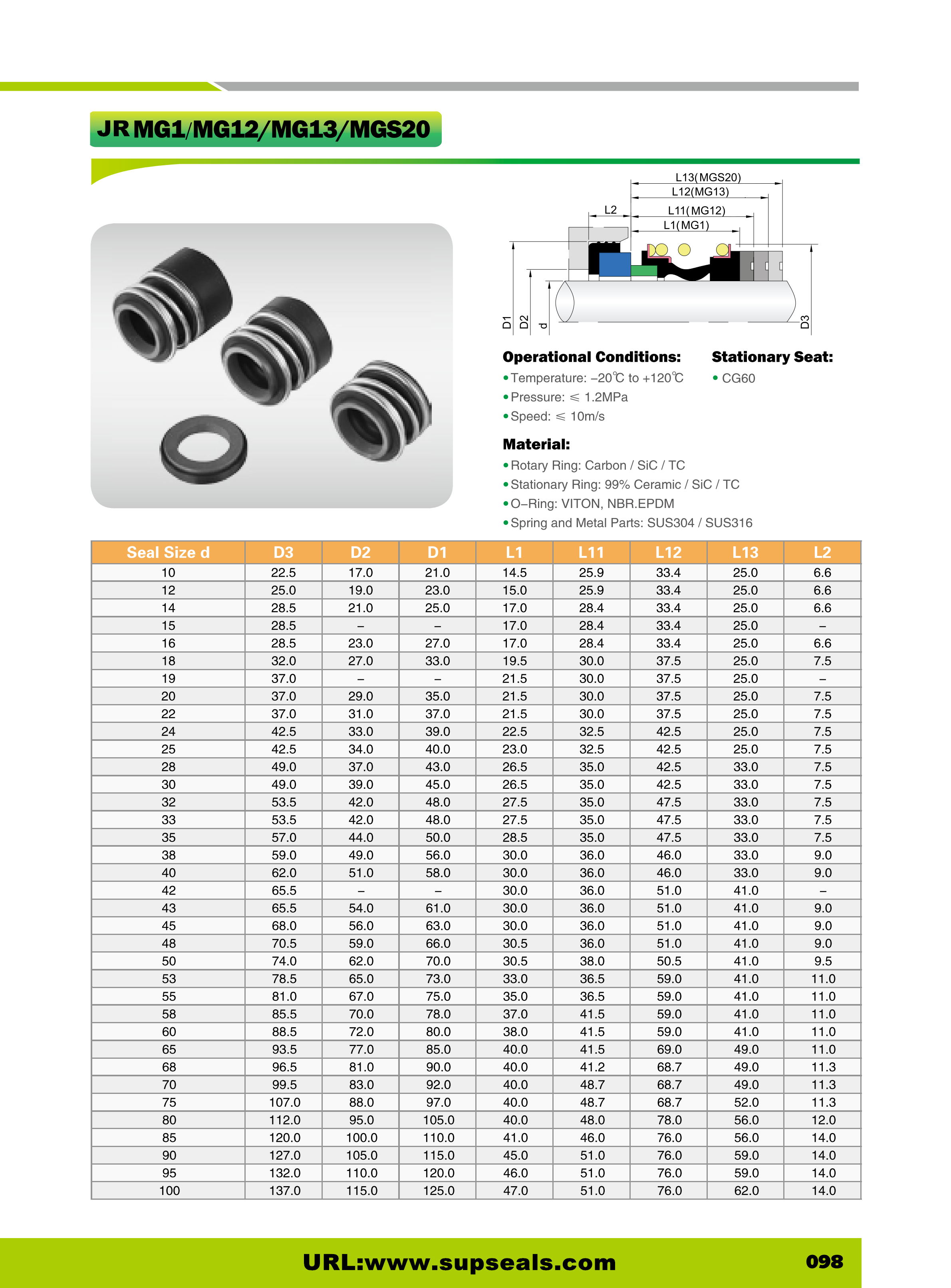

Rubber Bellow Mechanical Seal MG13 For Water Pump For Roten L3

Operations Conditions:

- Pumps: All types of rotating equipment, such as centrifugal pumps, agitators, for most general and light chemical duties, wherever an elastomer Secondary Seal can be used.

- Temperature: -30°C~200°C

- Pressure: ≤1.2MPa

- Speed: ≤ 12 m/Sec

- Design feature: Elastomeric bellows seal design including kinds of statconary ring, complying with DIN24960 and ISO3069, combined with P60, P50, t6, t4, T9, C606, etc.

Materials:

- Rotary Face: Carbon / SIC / TC.

- Stationary Seat: Ceramic / SIC / TC.

- Bellows: NBR / EPDM / VITON.

- Spring: SS304 / SS316.

- Metal Parts: SS304 / SS316.

|

Temperature

|

-30℃ to 200℃, dependent on the elastomer

|

|

Pressure

|

Up to 10 bar

|

|

Speed

|

Up to 15 m/s

|

|

End play/axial float allowance

|

±0.1mm

|

|

Size

|

12mm to100mm

|

|

Brand

|

LM

|

|

Face

|

Carbon, SiC, TC

|

|

Seat

|

Ceramic, SiC, TC

|

|

Elastomer

|

NBR, EPDM, VITON etc.

|

|

Spring

|

SS304, SS316

|

|

Metal parts

|

SS304, SS316

|

|

Packing Detail

|

1.From 12mm to 20mm is packed in plastic sheets grouply and M box.

2.From 22mm to 100mm is wrapped in plastic paper individually then grouply in M box. 3.Individual packing ,1 pc in 1 small box is available as well with cost of packing added. |

- Mechanical seal MG13 - is lees commonly used among "MG" seria. The dimensions are the same as for MG1 and MG12, but with prolonged plain spigal portion of the bellows for providing the mounting length.

- The seal is applied to cenrifugal pumps for water and drainage water.

- Application to the following pumps is available: Grundfos (NB).

At the meantime, we could manufacture seals according to your sample or

drawing, and design as your request.

With advanced designer&manufacturer of machanical seal, for industrial pump,

its range involves in: industrial pump mechanical seal, mixer and agitator seal,

cartridge seal, metal bellows seal, auto cooling pump seal and suto air-condition compressor lip seal.

It is widely used and highly reliable in food, drink, petroleum, chemistry,

refinery, paper making, pharmacy, power and auto industry etc.

Characteristics:

High and low temperature resistant, acid-alkali resistant, ozone resistant, aging resistant, weather resistant, good

insulation property, anti-toxic, good air-permeable, etc.

All ranges of mechanical seals for Flyg-t Pumps, Grund-fos Pumps, Pumps, AP-V Pumps, G-rindes Pumps, Fristam, A-BS, All-eeiler, E-MU, GEA Tun-chenhagen, God-win, Hid-rostal, Hil-ge, Johns-on, Lo-wara, Wauk-esha, Vog-elsang Pumps etc

Welcome to quote for more details.

-

we could manufacture seals according to your sample or drawing, and design as your request,Customization: Changes of materials for getting other operating parameters are possible. Contact us with your requirements.

Question 1: Are you a factory or a trade company?

Answer: We are a factory and have our top sales for the trade service.

Question 2: Can I try to get a SAMPLE before the order?

Answer: Sure. You can ask for the samples. Usually they're free.

Question 3: Where is your factory located? How can I visit there?

Answer: Our factory is located in Ningbo, China. You can fly to

Ningbo or Shanghai airport directly. All our clients, from home or abroad,

are warmly welcome to visit us!

Question 4: How does your factory do regarding quality control?

Answer: Quality is priority. We always attach great importance to q

uality controlling from the very beginning to the very end.

Our factory has gained ISO9001 authentication.

Question 5: How about the lead time?

Answer: Within10-20 days after getting the prepayment.

Question 6: How can we pay?

Answer: For small sample shipping cost, you can pay either by paypal

or by T/T. And by T/T at sight for large amount of the order.

Question 7: If OEM available?

Answer: Yes, we provide all of our products OEM /ODM service.

Question 8: If I can buy pumps or pump parts from your company?

Answer: Yes , we also provide pumps and pump parts, such as Lobe pumps,

Compound & homogeneous pumps, Homogeneous & emulsification pumps

and so on. Please kindly visit our website:

www.supseals.com