- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Y) (mm):

-

550

-

Dimension(L*W*H):

-

2700X2150X2600mm

-

Weight (T):

-

5 T

-

Range of Spindle Speed(r.p.m):

-

1 - 8000 r.p.m

-

Spindle Motor Power(kW):

-

7.5/11

-

Max. Table Load(kg):

-

550 kg

-

Feed Speed(mm/min):

-

20 - 5000 mm/min

-

Rapid Feed Speed(m/min):

-

24/24/18

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JUGAO

-

Voltage:

-

220/380V

-

Product name:

-

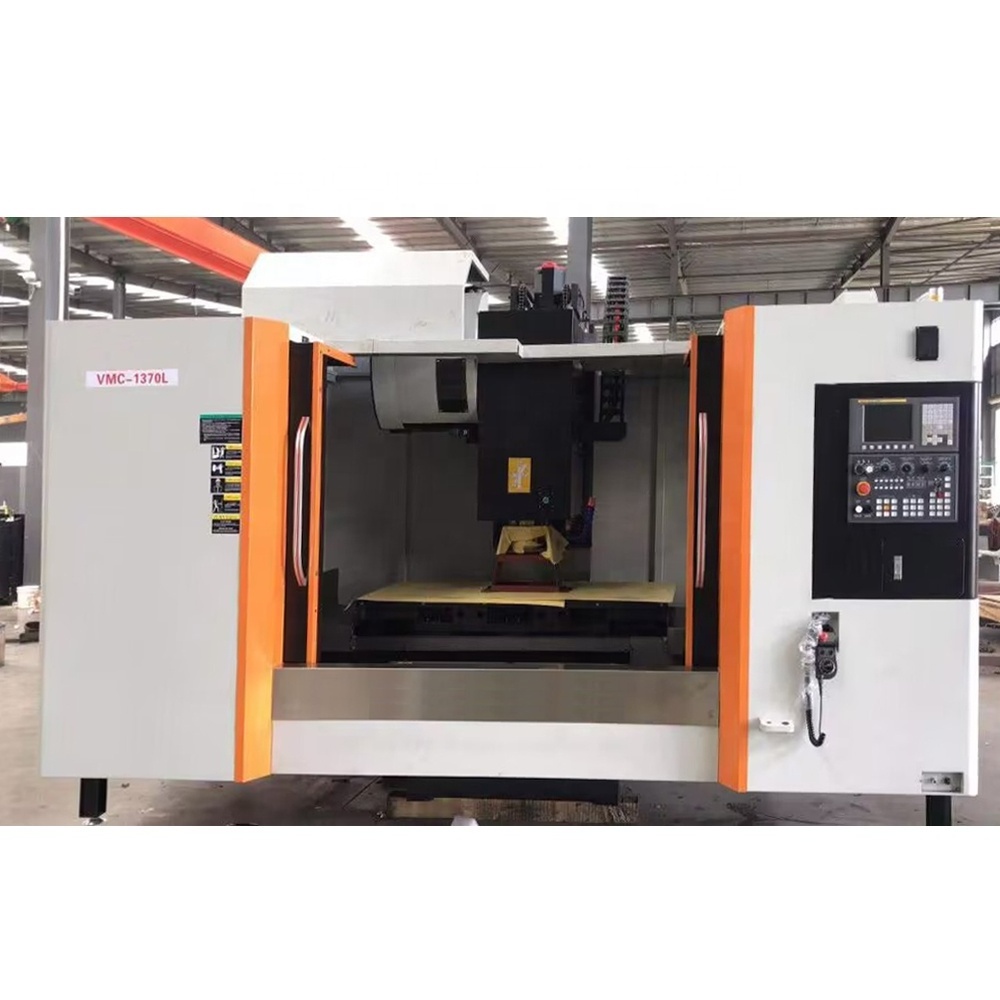

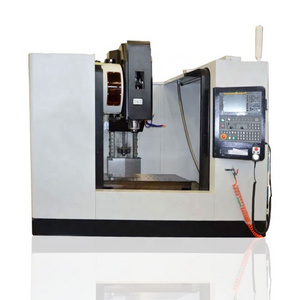

Vertical Machine Center

-

Machine tool lighting working lamp:

-

BT40 belt spindle

-

Spindles clean the air:

-

Centralized automatic feed lubrication system

-

Keyword:

-

Vertical Machine Center, CNC Milling Machine

-

Chip liquid system:

-

Spindle taper: BT40

-

10.4 "display:

-

Tricolor warning light

-

Servo transformer:

-

Separate handwheel

-

Foundation gasket and adjusting bolt:

-

RS232 interface

-

Random technical document:

-

Three ball type linear guide rail

-

cnc milling machine:

-

cnc vertical machining center vmc machine

Quick Details

-

Table Size (mm):

-

1000x550

-

Number of Axes:

-

3, 4

-

Table Travel (X) (mm):

-

800

-

Table Travel (Y) (mm):

-

550

-

Dimension(L*W*H):

-

2700X2150X2600mm

-

Weight (T):

-

5 T

-

Range of Spindle Speed(r.p.m):

-

1 - 8000 r.p.m

-

Spindle Motor Power(kW):

-

7.5/11

-

Max. Table Load(kg):

-

550 kg

-

Feed Speed(mm/min):

-

20 - 5000 mm/min

-

Rapid Feed Speed(m/min):

-

24/24/18

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JUGAO

-

Voltage:

-

220/380V

-

Product name:

-

Vertical Machine Center

-

Machine tool lighting working lamp:

-

BT40 belt spindle

-

Spindles clean the air:

-

Centralized automatic feed lubrication system

-

Keyword:

-

Vertical Machine Center, CNC Milling Machine

-

Chip liquid system:

-

Spindle taper: BT40

-

10.4 "display:

-

Tricolor warning light

-

Servo transformer:

-

Separate handwheel

-

Foundation gasket and adjusting bolt:

-

RS232 interface

-

Random technical document:

-

Three ball type linear guide rail

-

cnc milling machine:

-

cnc vertical machining center vmc machine

Intelligent And Convenient Operation Center Large Size Cnc Vertical Lathe And Milling Machine Machining Center

Performance characteristics

# Robust construction for efficient machining.

# HIWIN linear rail guide system for rapid feeds upto 8000mm/min.

# NSK high-precision bearing preloaded for ballscrews on all 3 axis.

# Armless(Umbrella)Type ATC(16-20 tools) Or Mechanical hand 24-station tool magazine as Optional.

#The rotary table(4thaxis,4+5th axis)as optional.

# Integrated coolant system.

# Chip conveyor and purge system for optimum chipremoval.

# Easy accessibility of work table foreasy setup and tooling.

# Enclosed work space ensures safe and contamination-free work.

# Different Operating system as optional: Siemens, Fanuc, Mitsubishi, GSK, Syntec. KN

Technical parameter

| Model | VMC650B | VMC850B | VMC1055B | VMC1370B | VMC1580B | VMC1890B |

| Travel(XAxis)(mm) | 650 | 850 | 1000 | 1300 | 1500 | 1800 |

| Travel(YAxis)(mm) | 500 | 550 | 550 | 700 | 800 | 900 |

| Travel (ZAxis)(mm) | 500 | 550 | 560 | 610 | 700 | 680(800) |

|

Distance: working table to spindle nose(mm) |

150-650 | 120-740 | 150-710 | 140-750 | 140-840 | 160-840 |

|

Distance:spindle to Vertical Guideway(mm) |

555 | 575 | 610 | 765 | 860 | 1060 |

| Working table size(mm) | 900X420 | 1000X550 | 1200X550 | 1400X710 | 1700X800 | 2000X900 |

| Max.load on table(kg) | 500 | 600 | 800 | 1000 | 1500 | 1600 |

| T shape groove | 3-18X100 | 5-18X100 | 5-18X100 | 5-22X120 | 5-22X135 | 5-22X160 |

| Taper hole of spindle | BT40- φ120 | BT40- φ150 | BT40- φ150 |

BT40- φ150 /BT50- φ155 |

BT50-- φ155 | BT50-- φ155 |

| Spindle speed (r/min) | 8000 | 8000 | 8000 | 8000 | 6000 | 6000 |

| Spindle power (kw) | 5.5/7.5 | 7.5/11 | 11/15 | 11/15 | 15/18.5 | 15/18.5 |

| Power(XYZ)(kw) | 1.5 | 2 | 3 | 3.5 | 4.5 | 4.5 |

|

Rapid moving speed X/Y/Z(m/min) |

24/24/18 | 24/24/18 | 24/24/18 | 24/24/18 | 24/24/18 | 24/24/18 |

| Feeding speed(mm/min) | 20-5000 | 20-5000 | 20-5000 | 20-5000 | 20-5000 | 20-5000 |

|

XY ZPositioning accuracy (mm) |

0.012 | 0.012 | 0.012 | 0.012 | 0.012 | 0.012 |

|

XY ZRepositioning accuracy (mm) |

0.006 | 0.006 | 0.006 | 0.006 | 0.006 | 0.006 |

| Dimension(mm) |

2400X2050 X2030 |

2700X2150 X2600 |

3200X2500 X3000 |

3700X2600 X2515 |

4310X2810 X2780 |

4800X3460 X4000 |

| Weight(Kg) | 4000 | 5000 | 6500 | 8500 | 12000 | 17000 |

Guarantee period:

Our product quality guarantee period is 12 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by customers’ incorrect operations, we will provide customers spare parts at cost price. We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials to do the test. Only guarantee the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services around the clock. If you need any help, contact us by WHATSAPP, Skype, Email or Telephone.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional recommendations; reg. non-standard products, we can offer professional designing.