- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

PE foam

-

Thickness:

-

1-100mm

-

Size:

-

1mx2m

-

Product Name:

-

PE foam

-

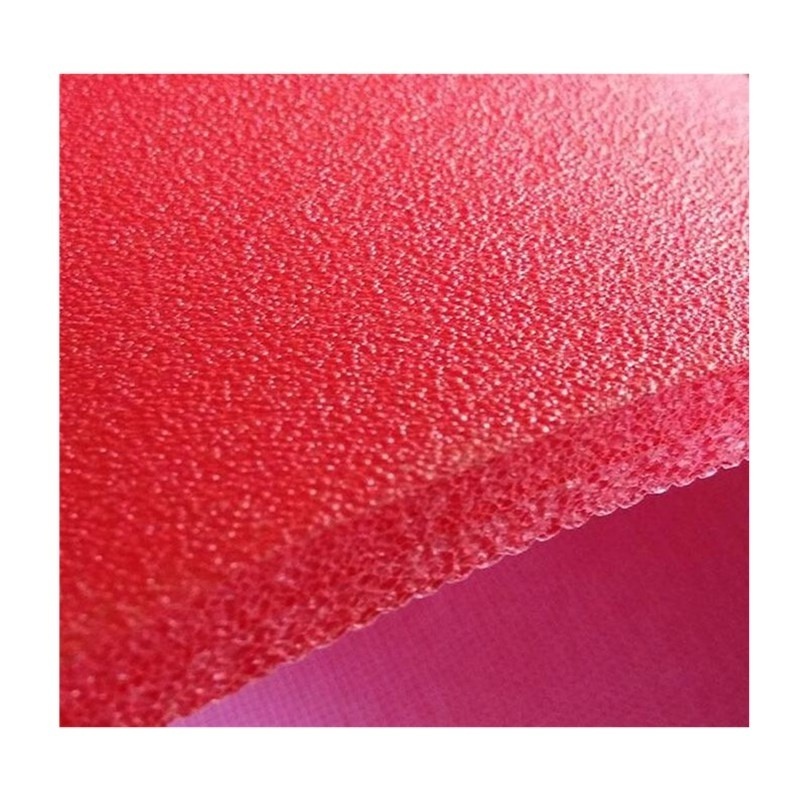

Color:

-

As Pantone color

-

Grades:

-

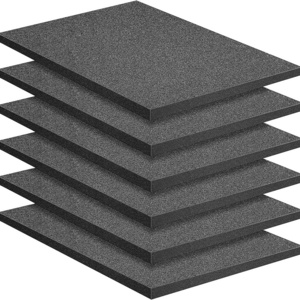

PE40, PE30, PE20, PE18, PE15

-

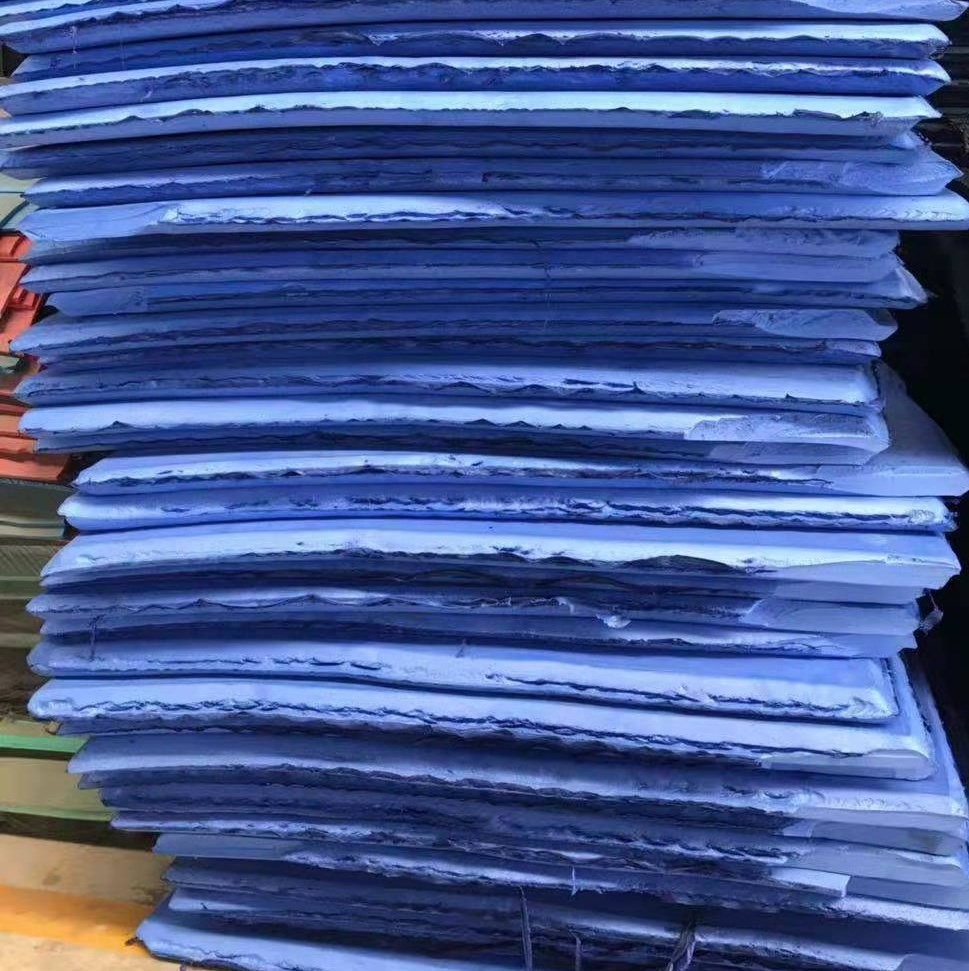

Shape:

-

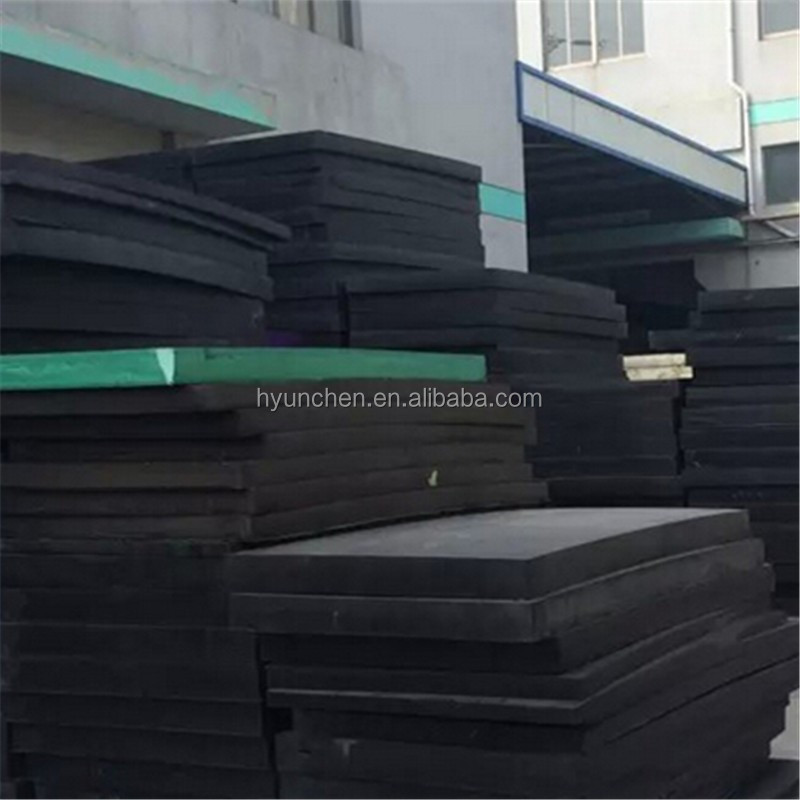

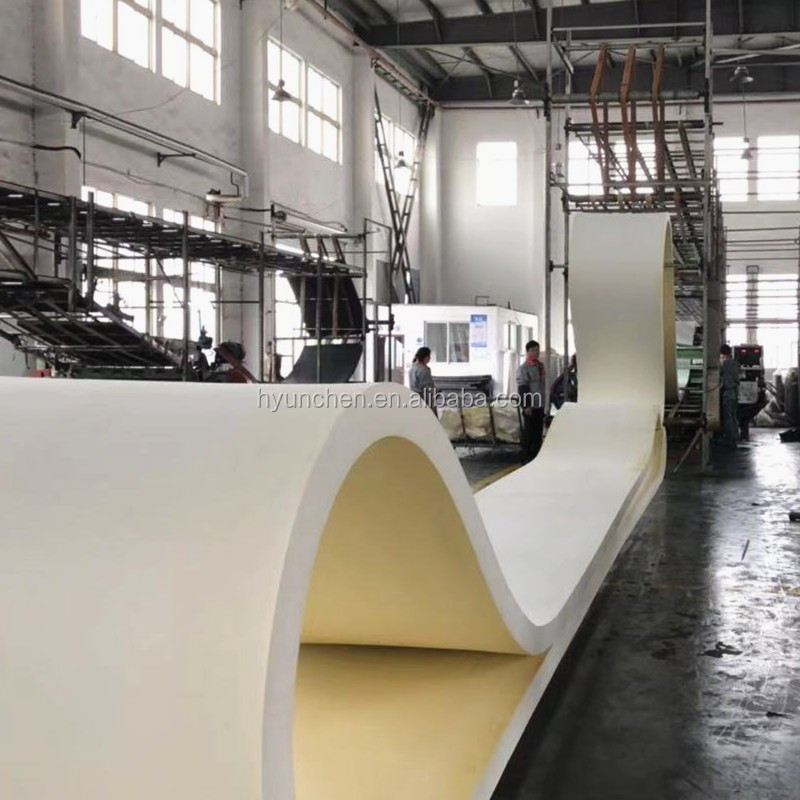

sheets and rolls

-

Density:

-

20-270kg/m3

-

Hardness (Shore C):

-

15-70 degree

-

Certificates:

-

SG S, ROHS, Reach

-

Service:

-

Die-cut, adhesive, etc.

-

Application:

-

Packing, sports, construction, automotive, etc.

-

More foam products:

-

Yoga Block, Swimming Pad, exerciase mat, etc.

Quick Details

-

Processing Service:

-

Cutting, Moulding

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Yunchen

-

Model Number:

-

PE foam

-

Thickness:

-

1-100mm

-

Size:

-

1mx2m

-

Product Name:

-

PE foam

-

Color:

-

As Pantone color

-

Grades:

-

PE40, PE30, PE20, PE18, PE15

-

Shape:

-

sheets and rolls

-

Density:

-

20-270kg/m3

-

Hardness (Shore C):

-

15-70 degree

-

Certificates:

-

SG S, ROHS, Reach

-

Service:

-

Die-cut, adhesive, etc.

-

Application:

-

Packing, sports, construction, automotive, etc.

-

More foam products:

-

Yoga Block, Swimming Pad, exerciase mat, etc.

Crosslinked PE Foam (in Sheet or in Roll):

PE Foam is the ideal packaging material for products that require surface protection and buffering against potential knocks or falls. Examples of such products include fragile items like high-tech equipment, components, glass, porcelain or products with lacquered surfaces. PE Foam is an exceptional product due to the fact that it is shock absorbent, dust-free, odourless,non-abrasive, insulating and water resistant. The material is also 100% recyclable and CFC-free, making it environmentally friendly. Benefits of XLPE Foam include:

Resistant to chemicals and grease.

Impervious to mildew, rot and bacteria.

Lightweight and flexible.

Wear and tear resistant.

Temperature resistant between -60℃ and 90℃.

|

Item

|

Grade

(Times)

|

Density (kg/m3)

|

Hardness (Shore C)

|

Tensile

(Kpa)

|

Elongation

(%)

|

|||||

|

XLPE Foam

|

40T

|

20-25

|

15

|

160

|

180

|

|||||

|

XLPE Foam

|

30T

|

30-35

|

25

|

250

|

220

|

|||||

|

XLPE Foam

|

20T

|

45-50

|

30

|

400

|

230

|

|||||

|

XLPE Foam

|

18T

|

60-70

|

35

|

450

|

250

|

|||||

|

XLPE Foam

|

15T

|

90-100

|

45

|

650

|

280

|

|||||

|

Flame-Retardent PE foam and higher densities are all available.

|

|

|

|

|

|

|||||

Q: Do you manufacture your own foam?

A: Yes, we do manufacture the foam using our own presses and molds. We have various sizes molds.

Q: Why your price labeled so cheap?

A: We manufacture the foam buns ourself, and export directly, no extra fees added.

Q: What is your lead time?

A: Ninety percent of all our orders can be loaded in 15 days.

Q: How much can you fit on a 40 HQ container?

A: Approximately 205 buns of 4" x 48" x 96", 330 buns of 100mmx1000mmx2000mm.

Q: What is your minimum order?

A: Our usual minimum order is 10cbm. Small qty will be cost a lot delivery cost.

Q:What are acceptable forms of payment?

A: We accept TT payment, Paypal, L/C, etc.

Q: What densities are available?

A: We stock 1.8lb to 18lb densities.

Q: What colors are available?

A: Charcoal, Light Charcoal, Grey, Mint Green, Blue, White, Yellow, Red, etc. as Pantone colors.

Q:Does your material come with skins?

A: Generally no, although some materials are available with skins upon request.

Q: What can be used to cut your foam?

A: Most tools that can be used to cut wood can also be used to cut our foam. These include table saws, band-saws, table routing, water-jet, etc.

Q: What is the working temperature of the foam?

A:Maximum continuous operating temperature of our foam is between -110°F to 180°F (-79°C to 82°C)

Q: Does the foam float?

A: Yes, it does; EVA and XLPE is a water resistant foam.

Q: What are the differences between EVA and XLPE?

A: EVA stands for ethylene vinyl acetate. Our XLPE and EVA foam products are similar materials and are difficult to distinguish.

The primary differences are that EVA is softer, more resilient, and has stronger recovery after compression. Whereas polyethylene foams are firmer and more resistant to heat. Both of them provide excellent protection and shock absorption for packaging applications.