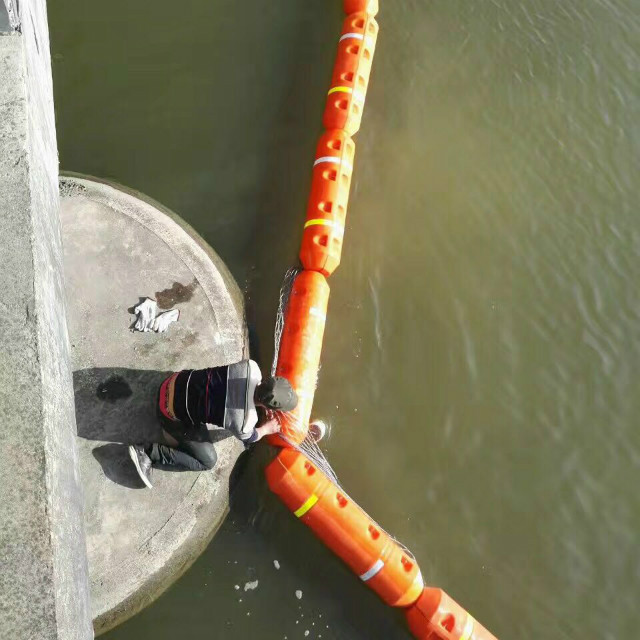

*They are made up of two half-shells whose internal and external diameters and total buoyancy are adapted to demand. The floats are assembled using a hinge and stainless steel or galvanized steel screws.

*The floats are filled with closed-cell eps foam with different density in base of the hydrostatic pressure the floats need to withstand.

*The two halves are connected each other on the pipe through four steel bolts, two each side to ensure optimal clamping with the pipe.