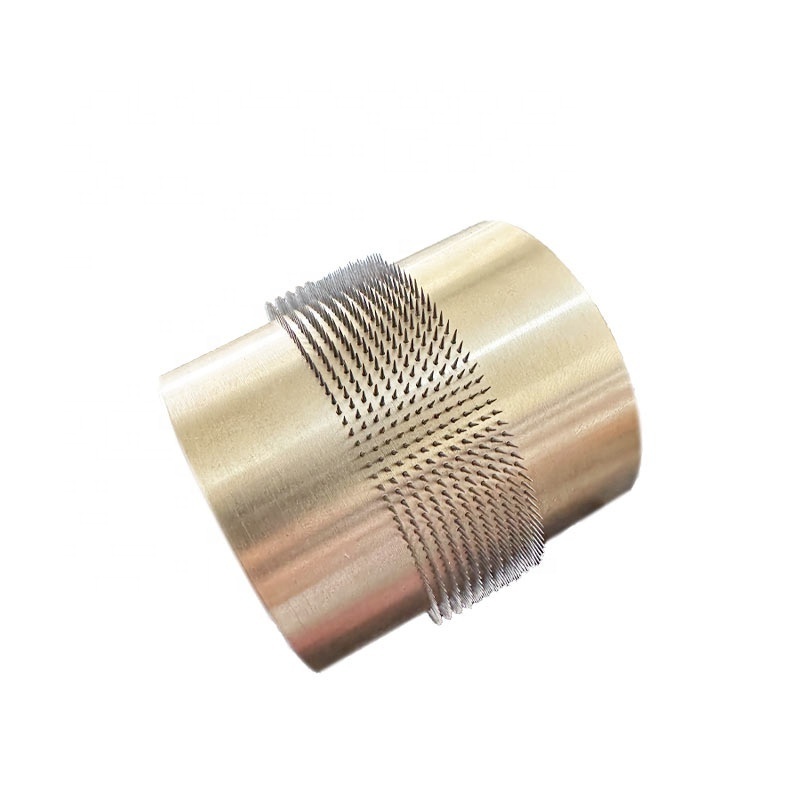

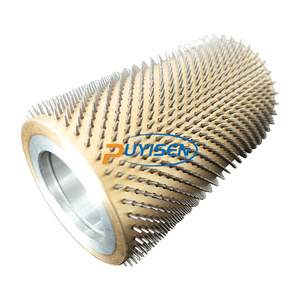

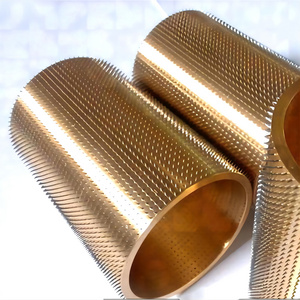

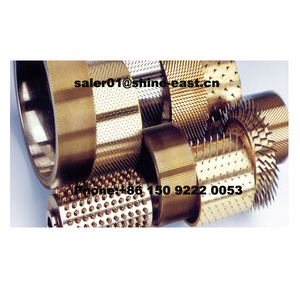

Smooth, rounded shape of a pin does much less damage to delicate fibre than conventional card-wire. The sharp point of a pin.

also gives excellent fibre penetration. The result is exceptional fibre opening with minimum fibre damage. Consequently staple length is maintained.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

To-faith&B-rt

-

Model Number:

-

DE045

-

Product name:

-

Needle roller

-

Material:

-

Needle and Tube

-

Application:

-

Textile&Fibrillation

-

Size:

-

Customer Designed

-

Certificate:

-

TUV

-

Filament material:

-

Metal Needle

-

Shape:

-

Cyclinder

-

Usage:

-

Perforating

-

MOQ:

-

1

-

Delivery Time:

-

15 Days

Quick Details

-

Type:

-

Industrial Brush

-

Bristle Length:

-

Custom

-

Warranty:

-

1 years

-

Place of Origin:

-

China

-

Brand Name:

-

To-faith&B-rt

-

Model Number:

-

DE045

-

Product name:

-

Needle roller

-

Material:

-

Needle and Tube

-

Application:

-

Textile&Fibrillation

-

Size:

-

Customer Designed

-

Certificate:

-

TUV

-

Filament material:

-

Metal Needle

-

Shape:

-

Cyclinder

-

Usage:

-

Perforating

-

MOQ:

-

1

-

Delivery Time:

-

15 Days

Product Description

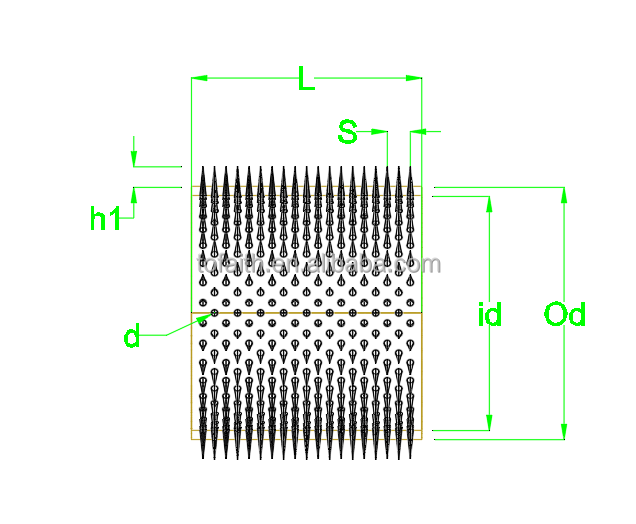

A fibrillating roller is a machine used in the fibrillation process, which is a mechanical method of separating fibers. This

process involves passing a material, such as paper or plastic, through a set of rollers with sharp teeth, which pull the fibers

apart and create a network of fine fibers.

The fibrillating roller is a key component of the fibrillation process, as it is responsible for creating the necessary friction

and pressure to separate the fibers. The roller is typically made of metal, and its surface is covered with a series of sharp

teeth or blades that grip the material and pull it through the machine.

Fibrillating rollers are commonly used in the production of non-woven materials, such as filters, insulation, and textiles. They can also be used to create specialized products, such as battery separators and medical dressings. The efficiency and quality of the fibrillation process depend on the design and condition of the fibrillating roller, as well as the characteristics of the material being processed.

process involves passing a material, such as paper or plastic, through a set of rollers with sharp teeth, which pull the fibers

apart and create a network of fine fibers.

The fibrillating roller is a key component of the fibrillation process, as it is responsible for creating the necessary friction

and pressure to separate the fibers. The roller is typically made of metal, and its surface is covered with a series of sharp

teeth or blades that grip the material and pull it through the machine.

Fibrillating rollers are commonly used in the production of non-woven materials, such as filters, insulation, and textiles. They can also be used to create specialized products, such as battery separators and medical dressings. The efficiency and quality of the fibrillation process depend on the design and condition of the fibrillating roller, as well as the characteristics of the material being processed.

Pins are "Fibre Friendly"

|

Product name

|

Fibrillating roller

|

Function

|

Perforating, embossing, and fibrillation

|

|

Base Material

|

Steel/copper/aluminum

|

Pin Material

|

Stainless steel

|

|

Size

|

Custom

|

Pin Density

|

Custom

|

Packing & Delivery

Hot Searches