- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

YD

-

Product name:

-

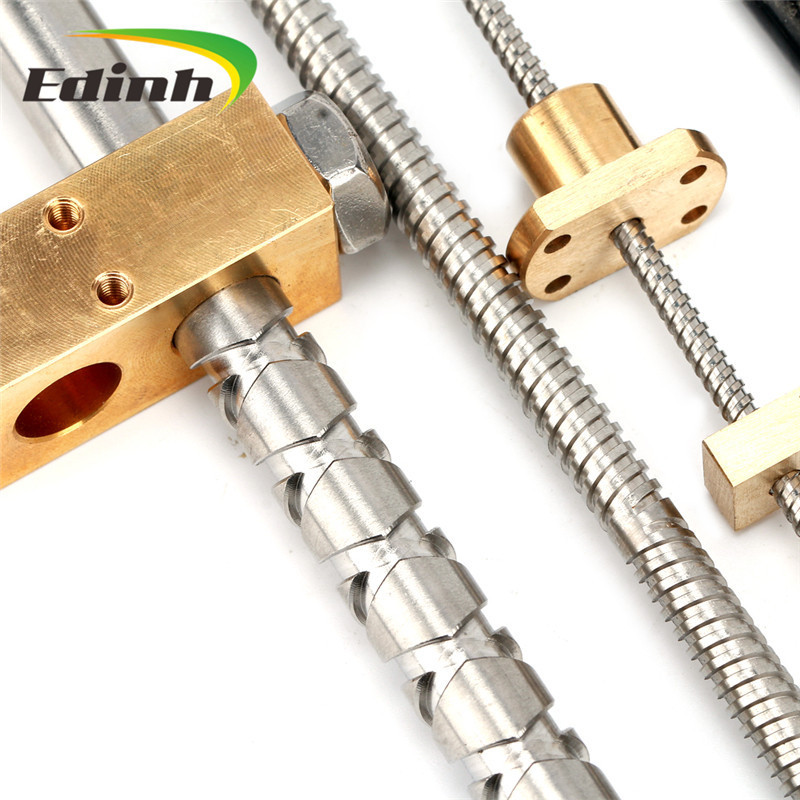

brass nut stainless steel screw

-

Application:

-

Cnc Machining Parts

-

Nut type:

-

Single Nut$ Double Nut

-

Feature:

-

Long Operating Life

-

Service:

-

OEM Customized Services

-

Nut:

-

Stainless steel or brass nut

-

After Warranty Service:

-

No service

Quick Details

-

Weight (KG):

-

1.5

-

Material:

-

GCr15, Stainless Steel ball screw

-

Length:

-

customizable

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

YD

-

Product name:

-

brass nut stainless steel screw

-

Application:

-

Cnc Machining Parts

-

Nut type:

-

Single Nut$ Double Nut

-

Feature:

-

Long Operating Life

-

Service:

-

OEM Customized Services

-

Nut:

-

Stainless steel or brass nut

-

After Warranty Service:

-

No service

Low Friction Brass Stainless Steel Self Reversing Screw Nut,Self Reversing Reciprocating Screw,Self Reversing Screw Shaft

Product Description

A crisscross thread pattern allows you to drive the nut back and forth without changing the lead screw's direction of rotation. When the nut reaches one end of the lead screw, it changes direction and travels back to the other end. Also known as diamond lead screws, they're sometimes used to guide cable and wire as it's spooled on a reel.

Travel distance per turn, also known as screw lead, is the distance the nut moves with one revolution of the lead screw.

Travel distance per turn, also known as screw lead, is the distance the nut moves with one revolution of the lead screw.

|

Product name

|

Low Friction Brass Stainless Steel Self Reversing Screw Nut,Self Reversing Reciprocating Screw,Self Reversing Screw Shaft

|

|

Manufacturing Process

|

Rolled thread and Milled thread, according to customer requirements

|

|

Available material

|

Gcr15, Gcr15SiMn, Chrome steel, stainless steel, alloy steel

|

|

Precision

|

C5, C7

|

|

Prepressure

|

P2 (common prepressure)

|

|

Hardness

|

59-63 HRC

|

|

Tolerance

|

0.002-0.005mm

|

|

Thread

|

usually right thread, part model can produce left thread. Please refer to the table below for details

|

|

Processing charges

|

please provide the drawings, the processing fee is calculated according to the requirements of the drawings, and if the nut is

needed, please contact the consulting quotation in advance |

|

Surface treatment

|

hot-dip, polishing, zinc plating, nickel plating, chrome plating, powder coating, phosphate coating, Anodizing, E-coating.

|

|

Applications

|

Electrical , Automotive , Mechanical, Building, Furniture,, Machine assembly, Computer, Air industry.

|

|

Related products

|

nuts, nut holders, couplings, support series, please refer to the specific products for details

|

|

Our services

|

According to drawings or samples for our customers to manufacture products

|

|

Package

|

1.Plastic bag+box case or wooden case. If the ball screw length is more than 3 meters ,please inform us in advance. We will check

the transport express information. 2.According to our customer's request, |

|

Delivery time

|

Generally 7-25 days, we determine the delivery time according to customer demand

|

Recommend Products

|

Diameter*Pitch*Stroke*Total length/mm

|

Material

|

|

5*5-28-80

|

Copper Nut

|

|

8*8-24-100

|

Copper Nut

|

|

10*10-50-150

|

Stainless steel

|

|

10*10-50-200

|

Stainless steel

|

|

10*10-80-330

|

Stainless steel

|

|

10*10-100-300

|

Stainless steel

|

|

10*10-120-300

|

Stainless steel

|

|

10*10-150-400

|

Stainless steel

|

|

10*10-180-400

|

Stainless steel

|

|

10*10-200-400

|

Stainless steel

|

|

10*10-250-500

|

Stainless steel

|

|

10*10-300-600

|

Stainless steel

|

|

12*12.05-72.3-168

|

Stainless steel

|

Application

SELF-REVERSING SCREW ASSEMBLIES

Screw assemblies, such as a lead screw or ball screw, are used in applications when rotational motion must translate to linear motion. However, when the application requires a single direction of rotation, self-reversing screw assemblies are the best option.

What Is a Self-Reversing Screw Assembly?

For most screw assemblies, you need a shift in direction to return the nut to the starting position of the application. The self-reversing screw requires no direction change, making it more efficient and useful when a change in direction would cause a problem. The design of the self-reversing screw uses a unique nut that has a follower blade in it. This matches with the grooves of the screw, allowing it to reciprocate motion.

Self-Reversing Screw Assemblies Applications

When are self-reversing screw assemblies needed? With several screw applications to choose from, it’s important to understand when the self- reversing option is necessary. The self-reversing screws are sometimes called level winders or spooling screws because of their ability to wind heavy cables successfully and neatly—and often thousands of feet long.

Let’s look at a list of common applications in which the self-reversing screw works well:

Spooling heavy cables on winches for offshore industries

Winding of ropes in crane construction

The application range of self-reversing screw includes: robots, CNC machine tools, transmission devices, aircraft parts (such as ailerons), medical equipment (such as X-ray equipment) and printing machinery (such as offset printing machines), etc.

Screw assemblies, such as a lead screw or ball screw, are used in applications when rotational motion must translate to linear motion. However, when the application requires a single direction of rotation, self-reversing screw assemblies are the best option.

What Is a Self-Reversing Screw Assembly?

For most screw assemblies, you need a shift in direction to return the nut to the starting position of the application. The self-reversing screw requires no direction change, making it more efficient and useful when a change in direction would cause a problem. The design of the self-reversing screw uses a unique nut that has a follower blade in it. This matches with the grooves of the screw, allowing it to reciprocate motion.

Self-Reversing Screw Assemblies Applications

When are self-reversing screw assemblies needed? With several screw applications to choose from, it’s important to understand when the self- reversing option is necessary. The self-reversing screws are sometimes called level winders or spooling screws because of their ability to wind heavy cables successfully and neatly—and often thousands of feet long.

Let’s look at a list of common applications in which the self-reversing screw works well:

Spooling heavy cables on winches for offshore industries

Winding of ropes in crane construction

The application range of self-reversing screw includes: robots, CNC machine tools, transmission devices, aircraft parts (such as ailerons), medical equipment (such as X-ray equipment) and printing machinery (such as offset printing machines), etc.

Hot Searches