Q1:

Which city is TUYAO in? how can I get to your factory? Are you a trading company or factory?

A1:

We are in Zhangjiagang city, two hours driving from Shanghai. We are factory. Manufacturing mainly beverage filling and packaging machines. We offer turnkey solutions with more than 12 years’ experience.

Q2:

If I want to buy a machine, what information do I need to tell you, do you need from me?

A2:

-What kind beverage you want to produce?

-bottle volume? 250ml, 330ml, 500ml, 750ml, etc.?

-Producing capacity requirement? How many bottles per hour?

-Raw water analysis report.

-Voltage and altitude.

Q3:

What kind of project do you provide?

A3:

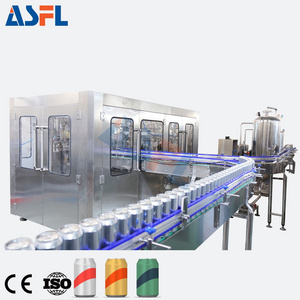

We provide filling system of aseptic, ultra-clean, hot, cold, still and with Co2. Our filling system can be used for filling

milk, beer, water, juice, soft drinks, spirits, sparkling wine or wine, coffee or tea, still or without Co2, hot or cold, whatever

drink you want to fill, TUYAO packaging will find the right solution for you, we also can provide you water treatment system,

juice processing system, label machine, PE film shrink packing machine, carton machine, robot palletizer.

Q4:

TUYAO how to ensure the quality?

A4:

-In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

- Each component before assembly needs strictly control by inspecting personnel.

- Each assembly is in charged by a master who has working experience for more than 5 years.

- After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory.

Q5:

How about the spare parts?

A5:

We will send one year enough easy broken spare parts together with the machines for free, we suggest you buy more units to save international courier such as DHL, it is really costly.

Q6:

Why are your prices higher than others?

A6:

We offer high-end machines in our business. Welcome to our factory to have a visit. And you will see the difference.

Q7:

What is your payment term?

A7:

30%T/T in advance as down payment, rest should be paid before shipping. L/C is supported also.

Q8:

Do TUYAO provide customized service?

A8:

We will customize the machine according to your needs,

Q9:

How to find TUYAO?

A9:

- Search Alibaba, Made in China, Google, Bing and type our name then you can find us.

- Send TUYAO a request and tell your basic inquiry

- TUYAO sales manager will reply you in short time and add instant chatting tool.

Q10:

How to guarantee your funds to be safe and deliver to be on time?

A10:

- Through Alibaba letter guarantee service, it will ensure the on-time delivery and the quality of the equipment you want to buy.

- By letter of credit, you can lock the delivery time easily.

- After the factory visit, you can ensure the facticity of our bank account.

Q11:

How is after-sale service of TUYAO?

A11:

- After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or by other instant tools.

- After the commissioning, we will package the equipment by standard export package for shipment.

- According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

- Engineers, sales managers and after-sales service manager will form an after-sales team, online and off line, to follow the customers' project.

-Solve basic questions by telephone, email, whatsapp, wechat and video call. Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines. Operating manuals will be sent with machine or by email. We also have overseas service center

Q12:

How to install my machines when it arrives? How much the cost?

A12:

We will send our engineers to your factory to install the machines and train your staff how to operate the machines If

needed. Or you can arrange engineers to study in our factory. You are responsible for air tickets, accommodation and our engineer allowance USD100/day/person.