- Product Details

- {{item.text}}

Quick Details

-

Power:

-

1.5KW/m

-

Dimension(L*W*H):

-

customized*2900*1650mm

-

Weight:

-

660 KG

-

Machinery Function:

-

baking bread cake or kinds of food

-

Output product name:

-

baking tunnel oven

-

Name:

-

bakery baking bread oven

-

Material:

-

Stainless steel

-

Power Source:

-

Electric or gas or diesel oil

-

Capacity:

-

cusomized

-

conveyor belt Width:

-

1400mm or 20000mm or customized

-

Tray Size:

-

400*600mm or 600*800mm or customized

-

Usage:

-

bread cake pizza duck biscuit and so on

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

Quick Details

-

Brand Name:

-

LINKON

-

Place of Origin:

-

Hebei, China

-

Voltage:

-

380/220

-

Power:

-

1.5KW/m

-

Dimension(L*W*H):

-

customized*2900*1650mm

-

Weight:

-

660 KG

-

Machinery Function:

-

baking bread cake or kinds of food

-

Output product name:

-

baking tunnel oven

-

Name:

-

bakery baking bread oven

-

Material:

-

Stainless steel

-

Power Source:

-

Electric or gas or diesel oil

-

Capacity:

-

cusomized

-

conveyor belt Width:

-

1400mm or 20000mm or customized

-

Tray Size:

-

400*600mm or 600*800mm or customized

-

Usage:

-

bread cake pizza duck biscuit and so on

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

Industrial Bakery Equipment Bread Cookie Baking Tunnel Oven Manufacturer

Products Description

1. Single-layer& double-layer tunnel furnace

2. Baking scope: Baking scope: kinds of bread, cakes, pizza, biscuits, moon cakes, pastry snacks, and so on

3. Suitable for the large capacity or continuous production of large-scale baking automatic assembly line

4. Custom-made by tray model: Horizontal position 2 trays, Horizontal position 3 trays, Horizontal position 4 trays

5. Oven length from 6m to more (by customer request or accroding for the production capacity)

6. The tunnel oven adopts high quality raw materials, Japan's self-running chain, world famous control originals, SEW, NSK, Schneide, Omron, Delta etc, which can make the oven reach over 20 years.

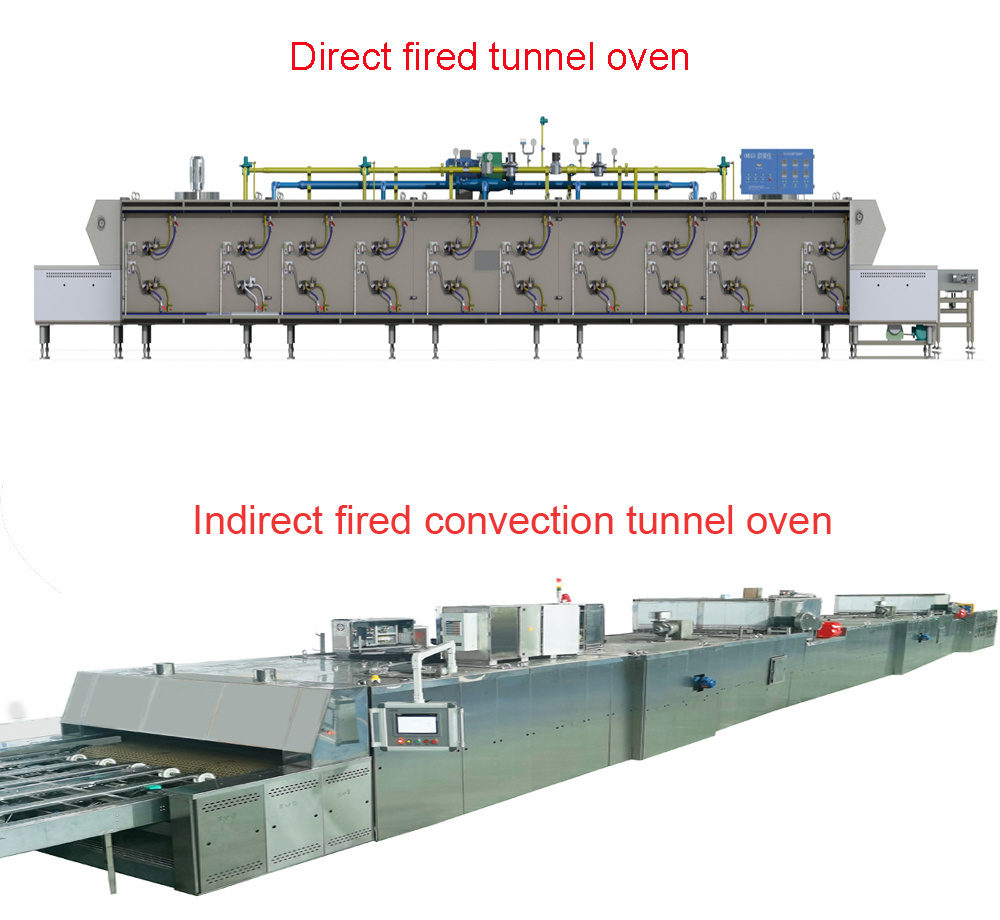

With two types oven:

Direct fired oven

Direct fired oven use the burner tubing heating principle, effective to ensure evenly baking, uniform color, use negative pessure

combustion principle, the safety of the oven operation is esured

Indirect heated convetion oven

The burner heats the combstion chamber and the heat exchange, then the air which will be blown into the bake chamber is heated through the heat exchanger. Thecombustion gas will not enter into the bake chmber and contact the produts.

2. Baking scope: Baking scope: kinds of bread, cakes, pizza, biscuits, moon cakes, pastry snacks, and so on

3. Suitable for the large capacity or continuous production of large-scale baking automatic assembly line

4. Custom-made by tray model: Horizontal position 2 trays, Horizontal position 3 trays, Horizontal position 4 trays

5. Oven length from 6m to more (by customer request or accroding for the production capacity)

6. The tunnel oven adopts high quality raw materials, Japan's self-running chain, world famous control originals, SEW, NSK, Schneide, Omron, Delta etc, which can make the oven reach over 20 years.

With two types oven:

Direct fired oven

Direct fired oven use the burner tubing heating principle, effective to ensure evenly baking, uniform color, use negative pessure

combustion principle, the safety of the oven operation is esured

Indirect heated convetion oven

The burner heats the combstion chamber and the heat exchange, then the air which will be blown into the bake chamber is heated through the heat exchanger. Thecombustion gas will not enter into the bake chmber and contact the produts.

Advantage:

1. Extremely low consumption of energy needed for baking

2. A large scale of baking surface :Possibility of baking surfaces (from25 to 165m2).

3. Product variety :Be universal ovens used for continuous baking of all types of bread and cakes which requires baking

temperature up to 320 oC

4. Transport through the baking area can be executed by means of materials. The heading medium used can be oil, gas or combination

of these two. It operates as an independent unit or within automated lines.

5. Adjustable diagram of baking time and temperature which are connectively adjustable.

6. Modular design: We build all our ovens with a modular design. This makes them simple to configure, build, install and even

modify based on your unique requirements-much more so than conventionally-built equipment from other manufacturers.

7. Saving of heat energy with the use of insulation materials, automatic regulation of traction in the baking zone.

8. Independent temperature regulation for the top and bottom of the baking chamber. In the baking area temperature can be

separately regulated up-down.

9. The oven inlet and outlet are adjusted according to other equipment or buyer's requirements.

10. The conveyor belt is self-centering and its tension is automatically adjusted and maintained at an optional level.

11. The framework of main body is made of enlarged and extra strong steel, which is high-quality, avoiding distorts due to

long-time overheat

Details Images

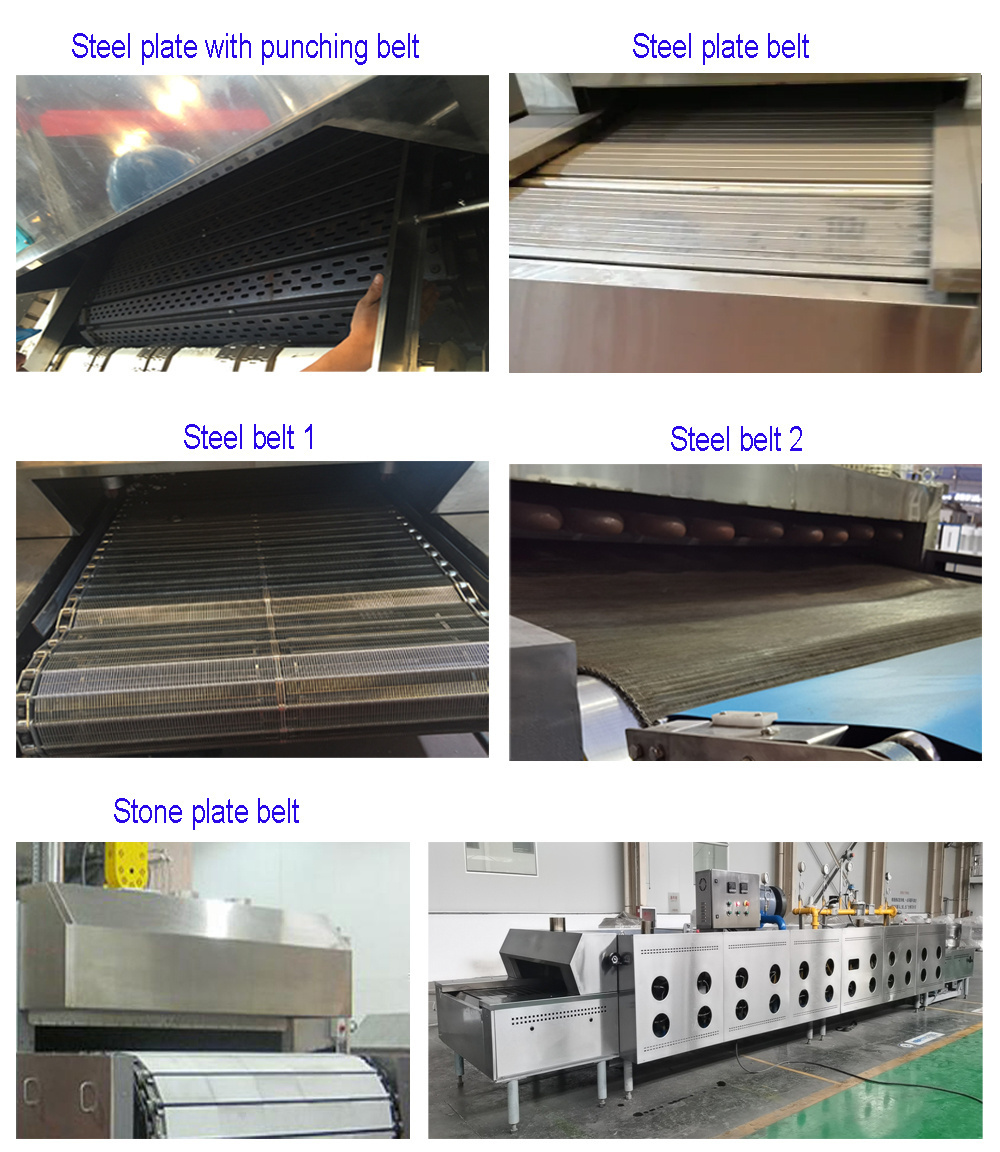

Kinds of belt for different food:

Baking kinds of the bread:

Product Paramenters

Electric tunnel oven

|

Specification

|

Inside height

(mm)

|

Inside width

(mm)

|

Outside height

(mm)

|

Outside height

(mm)

|

Power

|

Tray size (mm)

|

|

2 trays

|

850

|

1400

|

1600

|

2050

|

14kw/m/h

|

600*400

600*800

|

|

3 trays

|

850

|

2000

|

1600

|

2650

|

21kw/m/h

|

600*400

600*800

|

|

4 trays

|

850

|

2650

|

1600

|

3300

|

30kw/m/h

|

600*400

600*800

|

Gas tunnel oven

|

Specification

|

Inside height

(mm)

|

Inside width

(mm)

|

Outside height

(mm)

|

Outside height

(mm)

|

Gas consumption (LPG)

|

Gas consumption (NG)

|

Tray size (mm)

|

|

2 trays

|

850

|

1400

|

1600

|

2200

|

0.76kg/m/h

|

0.84m3/m/h

|

600*400

600*800

|

|

3 trays

|

850

|

2000

|

1600

|

2800

|

1.14kg/m/h

|

1.25m3/m/h

|

600*400

600*800

|

|

4 trays

|

850

|

2650

|

1600

|

3450

|

1.71kg/m/h

|

1.9m3/m/h

|

600*400

600*800

|

Widely use for the automatic bread line:

Related products

Hot Searches