- Product Details

- {{item.text}}

Quick Details

-

Power:

-

22.5kw

-

Dimension(L*W*H):

-

Accordingly

-

Weight:

-

1000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Working Vapor Pressure:

-

0.4~0.6Mpa

-

Working Vapor Consumption:

-

500kg/h

-

Evaporation Capacity(water):

-

1500kg/h

-

Evaporation Temperature:

-

1st 78℃/2nd 62℃/3rd 50℃

-

Heating Temperature:

-

1st 83℃/2nd 67℃/3rd 55℃

-

Water Consumption:

-

12T/h

-

Substrate:

-

TAS, SUS316L

-

Keywords:

-

1000l/hr 2000l/hr 2500l/hr Triple Effect Falling Film Evaporator Price

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Chengdong

-

Voltage:

-

Accordingly

-

Power:

-

22.5kw

-

Dimension(L*W*H):

-

Accordingly

-

Weight:

-

1000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Working Vapor Pressure:

-

0.4~0.6Mpa

-

Working Vapor Consumption:

-

500kg/h

-

Evaporation Capacity(water):

-

1500kg/h

-

Evaporation Temperature:

-

1st 78℃/2nd 62℃/3rd 50℃

-

Heating Temperature:

-

1st 83℃/2nd 67℃/3rd 55℃

-

Water Consumption:

-

12T/h

-

Substrate:

-

TAS, SUS316L

-

Keywords:

-

1000l/hr 2000l/hr 2500l/hr Triple Effect Falling Film Evaporator Price

1000l/hr 2000l/hr 2500l/hr Triple Effect Falling Film Evaporator Price

This 1000l/hr 2000l/hr 2500l/hr Triple Effect Falling Film Evaporator Price is used for glucose, starch, pharma, chemical, food, light industry and sewage treatment etc. industries, especially suitable for thousands tons VC production.

Material is distributed evenly into each tubes through the distribution device at the top of each Evaporator, material turns to film and flow from up to down due to its self-gravitating, pump pressure and 2 nd Vapor Stream, meanwhile, containing water is evaporated when material heat exchange with the heating steam outside the evaporating tubes.

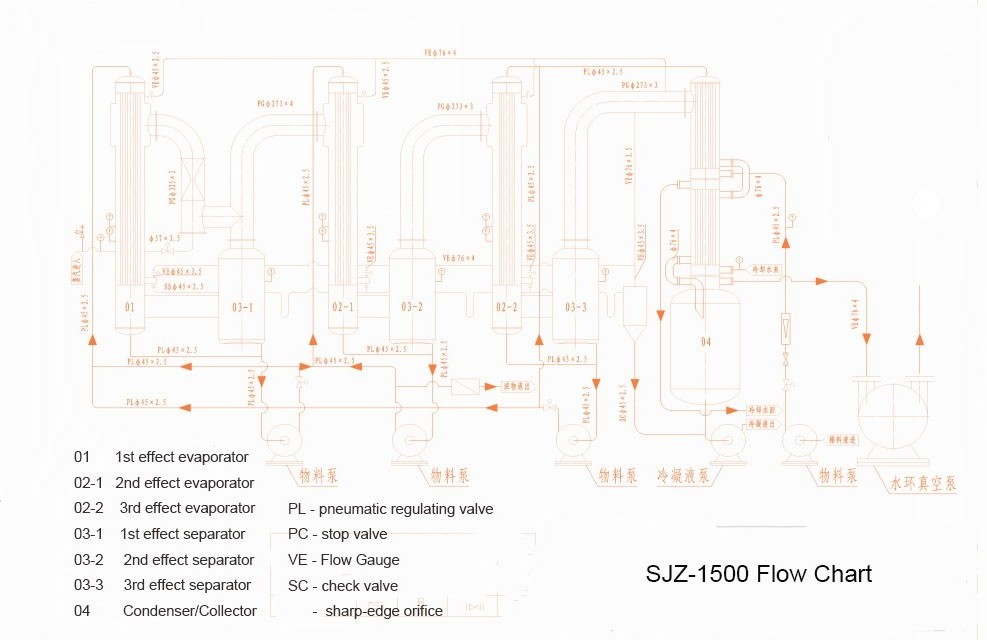

Process as per flow chart: Liquid material goes into the upper inlet of middle part of Condenser first, after preheating, flows down from distribution device at upper part of 3 rd Evaporator, then pump from the bottom of 3 rd Evaporator and 3 rd Separator to the distribution device at the upper part of 1 st Evaporator by material pump, then flows down, then pump from the bottom of 1 st Evaporator and 1 st Separator to the distribution device at the upper part of 2 nd Evaporator by material pump, then flows down, final product can be discharged from the bottom of 2 nd Evaporator and 2 nd Separator directly.