- Product Details

- {{item.text}}

Quick Details

-

Machine Type:

-

soap making machine

-

Marketing Type:

-

Hot Product 2024, Hot Product 2024

-

Keywords:

-

Soap Maker

-

Soap shape:

-

Customized Shape

-

Function:

-

Soap Automatic Production Line

-

Capacity:

-

100-3000KG/H

-

Name:

-

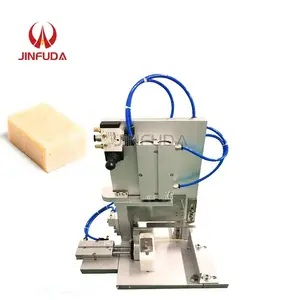

small soap making machine

-

Product name:

-

small soap making machine

-

Finally products:

-

Bath Soap Toilet Soap

-

Usage:

-

Laundry Soap Stamping Machine

-

Type:

-

Laundry Soap Bar Production Line

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

BS

-

Weight (KG):

-

1000

-

Machine Type:

-

soap making machine

-

Marketing Type:

-

Hot Product 2024, Hot Product 2024

-

Keywords:

-

Soap Maker

-

Soap shape:

-

Customized Shape

-

Function:

-

Soap Automatic Production Line

-

Capacity:

-

100-3000KG/H

-

Name:

-

small soap making machine

-

Product name:

-

small soap making machine

-

Finally products:

-

Bath Soap Toilet Soap

-

Usage:

-

Laundry Soap Stamping Machine

-

Type:

-

Laundry Soap Bar Production Line

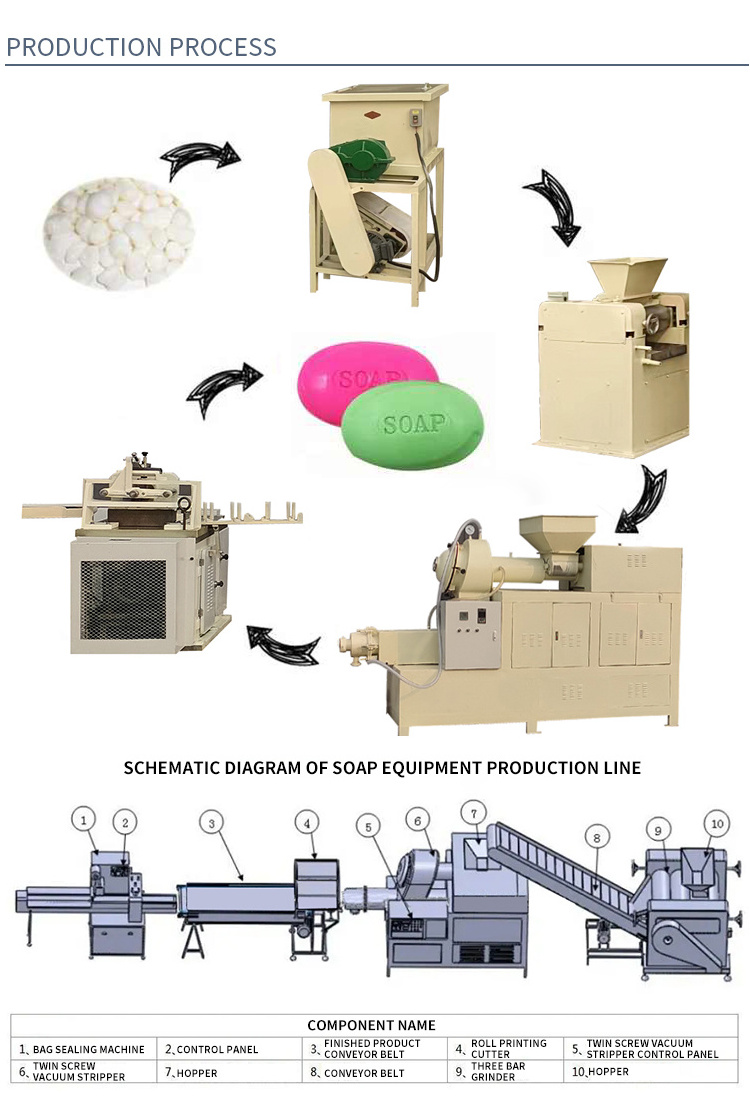

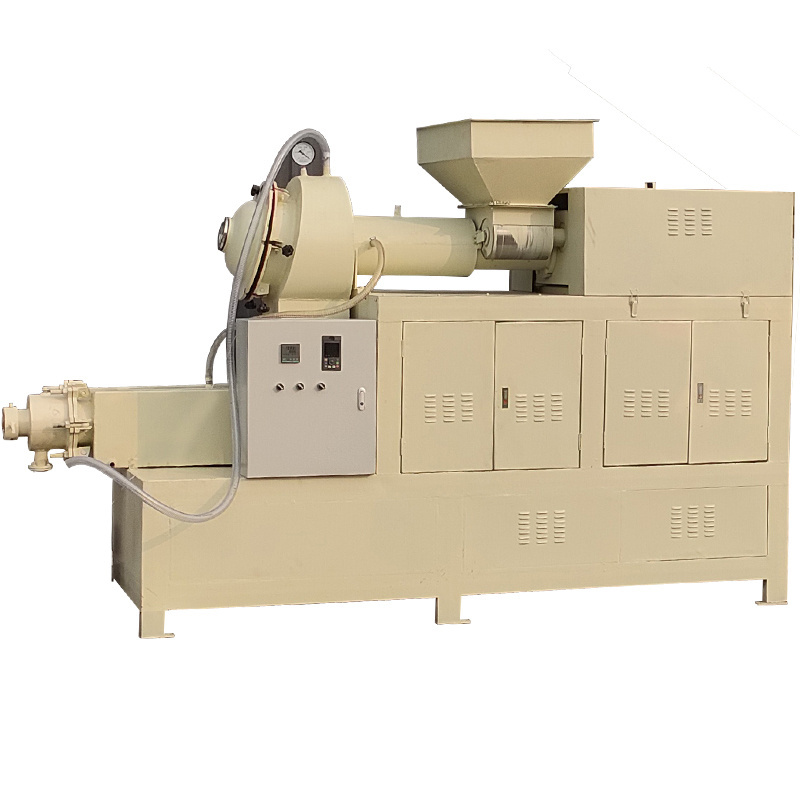

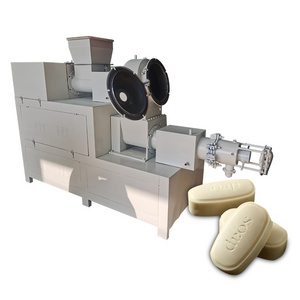

A soap mixer machine is used for the mixing of soap ingredients to create a uniform and cohesive soap mixture. It is a mechanical device that can be operated manually or automatically and is designed to meet the specific needs of soap manufacturing. The machine is made of high-quality stainless steel and has a heavy-duty design that ensures durability and longevity.

The soap mixer machine has a mixing bowl, which can come in varying sizes depending on the required capacity. The bowl is fitted with a powerful motor that drives the mixing blades or impellers. These blades are strategically positioned and shaped to allow for optimal mixing and emulsification of the soap ingredients.

Some soap mixer machines are designed to work in a vacuum, which helps to eliminate air bubbles in the mixture, resulting in a smoother and more consistent final product. The soap mixer machine may also have heating and cooling capabilities to maintain the ideal mixing temperature.

The soap mixer machine is easy to clean and maintain, making it ideal for use in soap production facilities of all sizes. It can be used to mix various soap ingredients such as oils, fragrances, and colorants to create a wide range of soap types and textures.

Specification

| Product name | Parameter |

| mixing tank | Power: 2.5kw/hour,size:1500*1000*1100mm |

| Three-roll grinding machine |

Drum diameter: 1700mm Power:2.2kw size:850*850*1000mm Weight:550kg |

| Duplex vacuum strip machine | Capacity: 150kg/hour |

| Control cabinet |

motor power: 4kw size: 4000*1000*2450mm weight:1900kg |

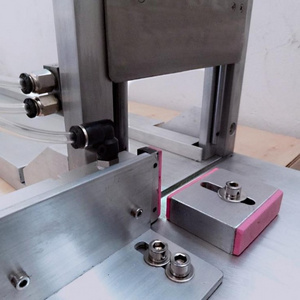

| Soap printer |

60-120pcs/min Power:2.2KW Weight:950kg Size:1450*800*1100mm |

| Soap freezer |

Power: 3kw Work temperature: -17 degree Cool capacity: 6800kcal/hour pressure power:3kw Size:1500*700*1700mm Weight:560kg |

| Two-stage rotary vane vacuum pump |

Pumping volume: 8L/s Power: 1.5kw Size:51*31*39mm |

| Conveyor belt | Size: 4800*600*600mm |

Description

A soap mixer machine is used for the mixing of soap ingredients to create a uniform and cohesive soap mixture. It is a mechanical device that can be operated manually or automatically and is designed to meet the specific needs of soap manufacturing. The machine is made of high-quality stainless steel and has a heavy-duty design that ensures durability and longevity.