- Product Details

- {{item.text}}

Quick Details

-

Printing Type:

-

Offset printing

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

BENEME

-

Model Number:

-

Business Card 021

-

Product Name:

-

letterpress business cards

-

Material:

-

coated paper; cardboard paper; art paper

-

Size:

-

90*54mm; 85*55mm; 88.9*50.8mm or any other size

-

Color:

-

CMYK or pantone color

-

Printing:

-

offset printing ; screen printing; letterpress printing

-

Paper Weight:

-

200gsm; 300gsm; 450gsm; 600gsm; 900gsm...

-

Thickness:

-

0.3mm; 0.42mm; 0.76mm ...

-

Techniques:

-

lamination; embossed; spot UV; foiling; edge gilding etc.

-

MOQ:

-

200pcs

-

Packing:

-

plastic box+OPP bag+carton box

Quick Details

-

Paper Type:

-

Art Paper, Cardboard, Coated Paper, Corrugated Board, Duplex Board, Fancy Paper, Kraft Paper, Newsprint Paper, Offset paper, Cotton Paper

-

Product Type:

-

Business Card

-

Surface Finish:

-

Film Lamination

-

Printing Type:

-

Offset printing

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

BENEME

-

Model Number:

-

Business Card 021

-

Product Name:

-

letterpress business cards

-

Material:

-

coated paper; cardboard paper; art paper

-

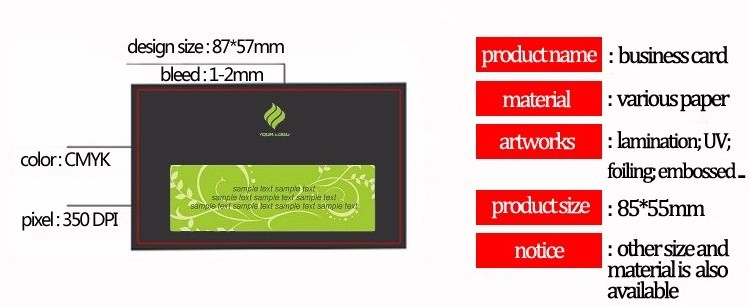

Size:

-

90*54mm; 85*55mm; 88.9*50.8mm or any other size

-

Color:

-

CMYK or pantone color

-

Printing:

-

offset printing ; screen printing; letterpress printing

-

Paper Weight:

-

200gsm; 300gsm; 450gsm; 600gsm; 900gsm...

-

Thickness:

-

0.3mm; 0.42mm; 0.76mm ...

-

Techniques:

-

lamination; embossed; spot UV; foiling; edge gilding etc.

-

MOQ:

-

200pcs

-

Packing:

-

plastic box+OPP bag+carton box

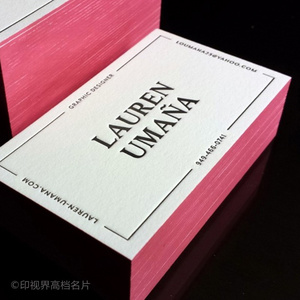

Custom High Quality Cotton Textured Letterpress Business Cards

High end raw material

We use the high quality paper material with environmental superior oil for printing to make sure the high printing clarity and quality.

Professional equipment

Our factory has the newest printing machine, to ensure the quality and efficiency. We can satisfy different customers' requirement from all over the world.

Various Paper Materials Available

There are many kinds of paper materials available for cards. Such as common flat paper series; texture paper series; pearl paper series. Just tell me the kind you want, we will find the perfect one for you.

Glossy/Matt Lamination

Glossy or matt lamination means to add a thin plastic film on the surface of paper.

This is usually used for coated paper businesss card, to make it shinier and firmer .

without lamination

glossy lamination

matt lamination

Embo ssing/Deb ossing/Letterpress

Embossing refers to the technique for creating

a raised pattern

on the card. While one side is embossed, the other side will be debossed. It is done with a mould.

Letterpress is a printing method. It is a technique of relief printing using a printing press. It can make the card look more professional.

Hot F oil Stamping

Hot foil stamping is the application of metallic or pigmented foil on to a solid surface by application of a heated die onto foil . It is a permanent process.

Foils come in a wide selection of colors and finishes, from the most commonly used metallic gold and silver to foils with pearlescent and holographic effects .

There are many colors available for foiling. Like:

red foil stamping

yellow foil stamping

purple foil stamping

bronze foil stamping

UV Coating

Edge Gilding

Edge gilding is to make the cards with a colored edge while not influencing its surface. It is a much more professional way than edge paiting.

Almost each color is available for edge gilding. But the most common ones are gold, silver and black edge gilding.

Die Cutting

Die cutting is a way to make the cards into various shapes you need with moulds.

step 1) Contact us for Quotation

Inquiry or Email or Skype or Trade manager

step 2) Confirm the artwork:

please provide us with AI; PDF; CDR format design artwork

step 3) Pay the deposit

step 4) Production

5-10 working days (if you are in urgent need of it, please inform us in advance, so that we can arrange the production for you sooner.)

ste

p

5) Make the balance payment

step 6) Delivery

We will take pictures for you before shipment

We are a modern printing and packaging company located in the beautiful city Hangzhou-"the heaven on earth".

Our main products are various types of printing and packaging items, like tags, stickers, business cards, brochures, catalogs, packaging boxes, jewelry boxes, cosmetic boxes, paper bags, fabric bags etc. Multiple materials and styles are available.

Our factory has the experience of over 20 years in the field of printing, with more than 300 employees, 25% technical personnel included. We have the newest advanced machines. Such as the German

Heidelberg four-color printing machine, automatic folding machine and wire binding machine, glue binding machine, digital cutter, foiling machine etc.

We take customers first by providing quality products, affordable prices, high-end services and efficient logistics. We respect each other not only among our company but also to our customers and we hold a high level of intergrity to our client. We welcome your inquiry at any time!

How to inquiry?

Pls tell me the material, size, artwork, quantity of the products you need as well as delivery method.

If you are the first time to do the items, just send me your similar pictures, or tell me your idea, we will give you suggestions for reference and if you need, we have our own designers who can design for you…

If you have your own designer, then you can first prepare your design files and then send us for printing.

How to Prepare Files?

For the files, it is best to prepare them as follows:

FILE FORMAT:

We accept file formats CDR and AI, the best design files for printing. PSD, PDF, JPG and PNG are also OK, but the resolution must be higher than 400DP, or there will be a substantial drop in the image quality

.

OUTLINE:

Outline means to change the words to paths or curves.

Since the word fonts in different computer do not match exactly, it may be missing or changed when open in a different computer. Therefore, to make sure the font is correct as well as to avoid the missing of your symbol and words, it is necessary for you to outline your press-ready designs.

BLEED:

Bleed is the portion of the product that will be trimmed off when it is cut in to the final size.

For cutting your product perfectly, a bleed is required to ensure that a white line does not show on the edges of your product.

We require all files to be built with full bleed dimension specified for each trim size.

We automatically trim the bleed off of each side, which will result in the desired trim size.

Usually the bleed is 0.125″ (3mm) on all four sides. So when you are making your file, please build your print-ready digital files by adding the appropriate bleed.

CROP MARKS:

Please build your press-ready digital files by adding crop marks, lines indicating where the paper should be cut to produce the correct size.

SAFE ZONE:

All critical elements (text, images, logos, etc.) must be kept at least 0.125″ (3mm) inside the edge. Anything left close to edge may be cut off during trimming.

How to get a sample?

After confirming the order, you can get my similar samples which we have producedbefore for checking the quality. The samples are free, but the shipping cost needs to be paid by you.

If you want a real printed sampleof your own design,we will charge some sample fees.

What if there is problem with the products after receiving?

Since printing products always has color deviation, we cannot promise to avoid that, but we will take pictures for you to check before shipping.

If it is other big mistakes made by us during production, we will reprint for you free of charge.

If you have any questions after receiving the products, you can just feel free to contact us.