- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50HZ

-

Power:

-

45KW

-

Dimension(L*W*H):

-

1000*1500*1200mm

-

Weight:

-

9000

-

Product name:

-

facial tissue paper making machine

-

Wetting system:

-

Automatic Wetting Liquid

-

Function:

-

Folding-wetting-cutting-counting-packing

-

Type:

-

30~120 Pcs/pack

-

Keyword:

-

Full-Auto Wet Wipes Machine

-

Pcs/Pack:

-

30-120

-

Name:

-

Automatic Single Piece Wet Wipes

-

Application:

-

Healthcare

-

Packing Speed:

-

35-60 Bags/minute

-

Brand:

-

ZOMAGTC

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZOMAGTC

-

Marketing Type:

-

Hot Product 2023

-

Voltage:

-

380V 50HZ

-

Power:

-

45KW

-

Dimension(L*W*H):

-

1000*1500*1200mm

-

Weight:

-

9000

-

Product name:

-

facial tissue paper making machine

-

Wetting system:

-

Automatic Wetting Liquid

-

Function:

-

Folding-wetting-cutting-counting-packing

-

Type:

-

30~120 Pcs/pack

-

Keyword:

-

Full-Auto Wet Wipes Machine

-

Pcs/Pack:

-

30-120

-

Name:

-

Automatic Single Piece Wet Wipes

-

Application:

-

Healthcare

-

Packing Speed:

-

35-60 Bags/minute

-

Brand:

-

ZOMAGTC

ATTENTION

1.Factory Direct price

2.Nice quality,

No MOQ, 1 set

is factory price too

3.Quick shipping within 15 days,

After sales service 24/7

Product Description

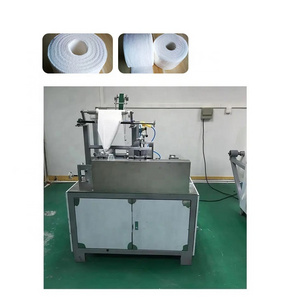

Full Automatic Production Line Wet Tissue Folding Cutting Packing Machine Small Packs Wet Wipes Making Machine

Wet wipes machinery production line The automatic wet tissue machine is a machine that directly cuts the entire roll of base paper into width, folds, adds liquid, cuts to a fixed length, counts and stacks, and then automatically transports it to the packaging machine for packaging. All processes are from raw materials to packaged products All finished on the machine, the production process is fast and hygienic.

|

Product Name

|

Baby Wet Tissue Towel Packaging Machine Wet Tissue napkin Packing Machine

|

|

Model

|

ZM-HY2800

|

|

Model specification

|

40-120 pieces of wet tissue paper

|

|

Applicable materials

|

OPP/PE, PET/PE composite film, aluminized film

|

|

Production speed

|

200~280 stacks/min (5 or 6 pcs/stack) and 80 pcs 15 packs/min

|

|

Control system

|

PLC control system, color package touch screen

|

|

Folding method

|

shape folding (without continuous pumping)

|

|

Print plate thickness

|

7mm

|

|

Production speed

|

35~60 packs/min

|

|

Product expansion size

|

(150~230)×(150~250) mm (length×width)

|

|

Machine size

|

5500×3000×1800 mm

|

|

Product folded size

|

(150~230)×(90~120) mm (length×width)

|

Product Features

Full Auto Facial Wet Tissue Production Line Machine Selling Point

1. The length of the production product can be set directly on the touch screen, which is simple and convenient.

2. The adjustment of hole opening position and labeling position is directly operated on the touch screen, which avoids position changes caused by mechanical structure adjustment.

3. The whole machine adopts servo motor, which makes the machine run more stably, with lower noise, faster speed and high precision.

4. The machine is equipped with a date printer, which is convenient for customers to print the production date and batch number on the product.

5. Fixed adjustable bag making device, easy to adjust. Equipped with an adjustable bag maker, it is convenient for customers to change product specifications.

6. Equipped with gusseting device.

7. Work process: packaging film, printing production date, material opening, pasting large labels, pasting anti-tear labels,

leading to conveying, feeding on conveyor belts, entering and wrapping mechanism, middle sealing, leading to conveying, horizontal sealing and cutting , Finished product delivery.

3. The whole machine adopts servo motor, which makes the machine run more stably, with lower noise, faster speed and high precision.

4. The machine is equipped with a date printer, which is convenient for customers to print the production date and batch number on the product.

5. Fixed adjustable bag making device, easy to adjust. Equipped with an adjustable bag maker, it is convenient for customers to change product specifications.

6. Equipped with gusseting device.

7. Work process: packaging film, printing production date, material opening, pasting large labels, pasting anti-tear labels,

leading to conveying, feeding on conveyor belts, entering and wrapping mechanism, middle sealing, leading to conveying, horizontal sealing and cutting , Finished product delivery.

Recommend Products

Contact us

Contact Person: Bonnie

Tel/Whats App/Wechat: +86 15378758307

E-mail: sales1@superelec.cn

Tel/Whats App/Wechat: +86 15378758307

E-mail: sales1@superelec.cn

Packaging & Shipping

|

Packaging Details

|

|

Stong wooden box package

|

|

|

Port

|

|

The main ports in China, depends customers choice

|

|

|

Lead Time

|

1 pc

|

35 days

|

|

|

|

>1 pcs

|

To be negotiated

|

|

SHIPPING

1.By air, sea or combined transportation.

2.Express via FEDEX, TNT, UPS, DHL, EMS(AS your request)

3.Tracking Number will offer you immediately after delivery

3.Tracking Number will offer you immediately after delivery

4.Shipping cost depends on the shipping method, product quantity,weight, carton size and your area.

Hot Searches