- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99%

-

Voltage:

-

220v

-

Place of Origin:

-

Andorra

-

Brand Name:

-

MIC

-

Weight:

-

1100 KG

-

Product name:

-

Detergent filling machine

-

Capacity:

-

2000-3000bph

-

Filling range:

-

1000-5000ml

-

Control:

-

PLC+ Touch Screen

-

Material:

-

Stainless Steel 304

-

Filling head:

-

8 heads

Quick Details

-

Machinery Capacity:

-

20000BPH

-

Packaging Material:

-

Other

-

Filling Material:

-

Other

-

Filling Accuracy:

-

99%

-

Voltage:

-

220v

-

Place of Origin:

-

Andorra

-

Brand Name:

-

MIC

-

Weight:

-

1100 KG

-

Product name:

-

Detergent filling machine

-

Capacity:

-

2000-3000bph

-

Filling range:

-

1000-5000ml

-

Control:

-

PLC+ Touch Screen

-

Material:

-

Stainless Steel 304

-

Filling head:

-

8 heads

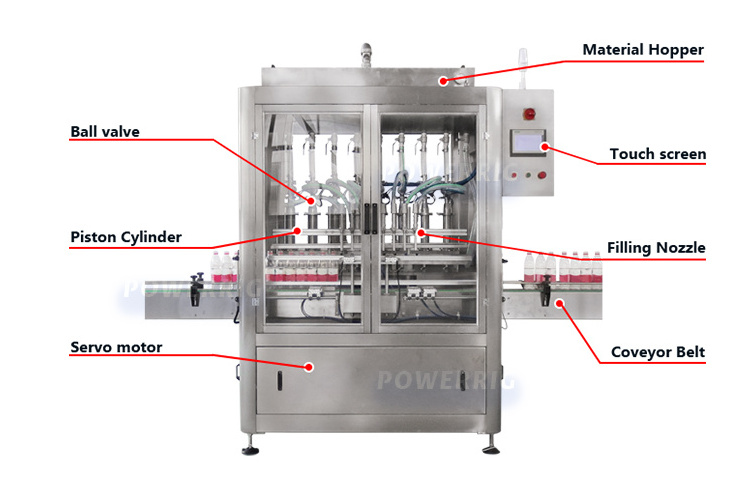

Product Introduction

This high viscosity viscous liquid volumetric filling sealing and capping machine piston filling machine ,widely used in Daily chemical industry, Cosmetic, food industry ,high viscosity materials, shampoo, hair condition cream, hand cream dish washing liquid and so on, the effect is obvious. Filling method can customize according to customer's different material , if customer's material is low viscosity material , suggest use gravity flow filling machine, if customer's material is high viscosity material , suggest use piston filling machine

If customer's material have many foam, also can customize vacuum filling and diving filling , If customer's haven't fluidity, easy to precipitation , can customize mixer and heating hopper above filling machine.

Difference:

Use servo motor double rod driven system make the filling volume accuracy reach 99% and machine running very stable. Filling volume adjustable no need change any part .Easy operate

|

Weight

|

700KG

|

|

Power

|

customized

|

|

Filling Volume

|

100-1000ml

|

|

Filling Error

|

≤3%

|

|

Suitable Filling Material

|

Oil,shampoo,detergent,sauce, honey, etc

|

|

Suitable Barrel Width

|

120-250mm

|

|

Dimension

|

2000*1300*2200mm

|

|

Power

|

1.5Kw

|

|

Filling nozzle

|

8 nozzles

|

|

Capacity

|

≤3000BPH

|

|

Suitable Barrel Length

|

180-330mm

|

|

Suitable Barrel Height

|

80-450mm

|

Filling Heads

Every filling head has anti-drop design. It promise do not waste the material. And diameter of filling head basis on the diameter of customer’s barrel’s mouth.

Piston Cylinder

The piston is drawn back in its cylinder so that the product is sucked into the cylinder. A rotary valve then changes position so that the product is then pushed out of the nozzle instead of back into the hopper.

Servo Motor

Servo motor can control the filling more accurate and also it can realize the filling nozzle diving bottom-up filling. At the same time, the filling volume can be adjusted on the touch screen and has automatic fine turning function for each filling head.

Anti-dripping system

This function is for prevent material dripping on the bottle and conveyor. And there will be a flexible plate coming out and back to take the dripping materials

Take off piston cylinder cleaning

piston will take off from the cylinder automatically ,then it will clean the Remaining materials that remain in the material tank and cylinder

Related Product

Company introduction

Hot Searches