- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1000 KG

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

220V/380V

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Turnkey tomato processing line

-

Application:

-

Tomato processing

-

Function:

-

Making tomato paste

-

Capacity:

-

2-300T/day

-

Advantage:

-

easy operation and energy saving

-

Package:

-

Wooden Case

-

Raw material:

-

Sainless Steel

-

Key words:

-

Tomato paste line

Quick Details

-

Machinery Capacity:

-

OEM

-

Brand Name:

-

CFM

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

1000 KG

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

220V/380V

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Turnkey tomato processing line

-

Application:

-

Tomato processing

-

Function:

-

Making tomato paste

-

Capacity:

-

2-300T/day

-

Advantage:

-

easy operation and energy saving

-

Package:

-

Wooden Case

-

Raw material:

-

Sainless Steel

-

Key words:

-

Tomato paste line

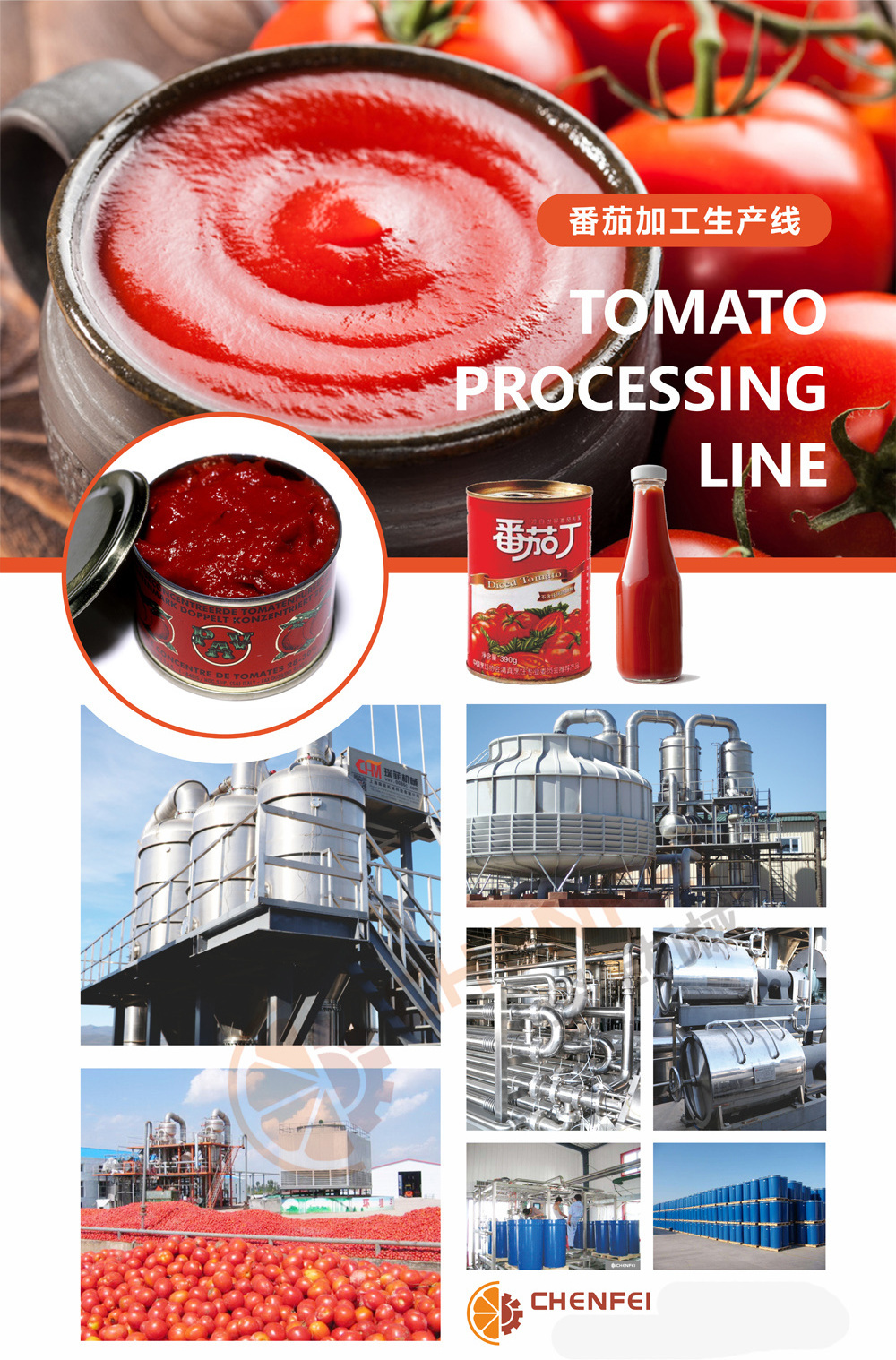

Tomato Paste Processing Line

Products Description

Description of Tomato Paste Processing Line:

Industrial machinery tomato paste diluting blending mixing vacuum concentrate small production line

Shanghai Chenfei Machinery offers complete tomato ketchup production line, on turnkey basis to produce the following end products

from tomatoes.

(1)Tomato puree from tomato processing plant;

(2)Tomato paste from tomato paste processing plant;

(3)Tomato ketchup/sauces from tomato ketchup puree plant;

(4)Tomato juices from tomato juice processing plant;

Packing lines can be offered depending upon the requirement like product in glass bottles, cans, drums, etc. Manufacturing process

involves most modern technology of vacuum evaporation using forced circulation evaporators/scrapped surface evaporators.

Evaporation plants are versatile in nature and can concentrate other juices also.

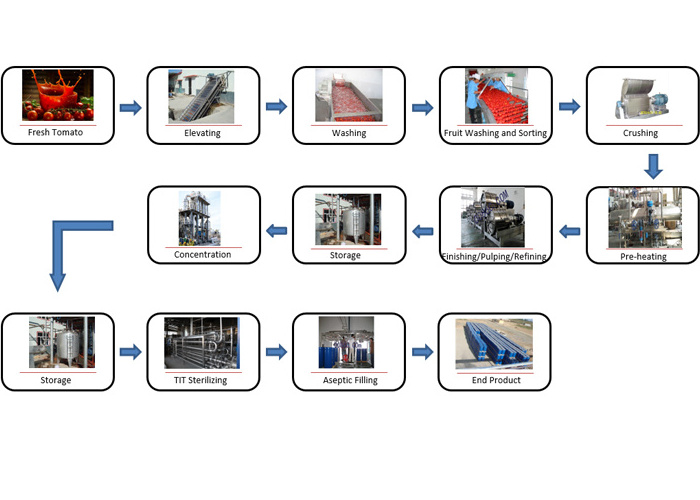

Production line machine composition:

A.fruit collecting and feeding;

B.tomato washing machine;

C.tomato sorting machine;

D.cold break tomato pulping machine;

E.tomato puree storage tank;

F.tubular tomato pre-heating machine ;

G.tomato refining machine;

H.tomato paste/sauce/ketchup evaporator;

I.tomato paste/ sauce/ketchup storage tank;

J.tomato paste/ sauce/ketchup sterilizer;

K.tomato paste/ sauce/ketchup aseptic filling machine.

Condition: New

Brand name: Shanghai Chenfei;

Type: whole processing Line/turnkey project/fruit and vegetables processing/dairy processing/beverage processing

Voltage: 220v/380v

Power(W): 100-200kw

Weight: Different size different weight/customized

Dimension(L*W*H): Different size different dimension/customized

Certification: CE&ISO

Warranty: 12 months/1 year

After-sales Service Provided: Engineers available to service machinery overseas

Main material: SUS304 or SUS316

Control type: automatic, semi-automatic

energy consumption: Low consumption with high efficiency

capacity: 500-10000L/H-customized

installation period: 1-3months

Period time: 30 days-120 days

Cups material: pouches, paper box, glass bottle, pet bottle, glass bottle

Product storage condition: room temperature; low temperature; .

Shanghai Chenfei Machinery offers complete tomato ketchup production line, on turnkey basis to produce the following end products

from tomatoes.

(1)Tomato puree from tomato processing plant;

(2)Tomato paste from tomato paste processing plant;

(3)Tomato ketchup/sauces from tomato ketchup puree plant;

(4)Tomato juices from tomato juice processing plant;

Packing lines can be offered depending upon the requirement like product in glass bottles, cans, drums, etc. Manufacturing process

involves most modern technology of vacuum evaporation using forced circulation evaporators/scrapped surface evaporators.

Evaporation plants are versatile in nature and can concentrate other juices also.

Production line machine composition:

A.fruit collecting and feeding;

B.tomato washing machine;

C.tomato sorting machine;

D.cold break tomato pulping machine;

E.tomato puree storage tank;

F.tubular tomato pre-heating machine ;

G.tomato refining machine;

H.tomato paste/sauce/ketchup evaporator;

I.tomato paste/ sauce/ketchup storage tank;

J.tomato paste/ sauce/ketchup sterilizer;

K.tomato paste/ sauce/ketchup aseptic filling machine.

Condition: New

Brand name: Shanghai Chenfei;

Type: whole processing Line/turnkey project/fruit and vegetables processing/dairy processing/beverage processing

Voltage: 220v/380v

Power(W): 100-200kw

Weight: Different size different weight/customized

Dimension(L*W*H): Different size different dimension/customized

Certification: CE&ISO

Warranty: 12 months/1 year

After-sales Service Provided: Engineers available to service machinery overseas

Main material: SUS304 or SUS316

Control type: automatic, semi-automatic

energy consumption: Low consumption with high efficiency

capacity: 500-10000L/H-customized

installation period: 1-3months

Period time: 30 days-120 days

Cups material: pouches, paper box, glass bottle, pet bottle, glass bottle

Product storage condition: room temperature; low temperature; .

|

Applicable Industries

|

vegetable&beverage industies

|

Condition:

|

New

|

|

Place of Origin

|

Jiangsu, China

|

Brand Name:

|

CHENFEI

|

|

Model Number:

|

customized

|

Type:

|

fruit and vegetable processing line

|

|

Voltage:

|

380V/220V

|

Capacity:

|

2-300T/day

|

|

Weight:

|

customzied

|

Dimension(L*W*H):

|

customized

|

|

Certification:

|

CE/ISO9001

|

Warranty:

|

1 Year

|

|

After-sales Service

|

Field installation, commissioning and training, Engineers available

|

Material:

|

304 /316 Stainless Steel

|

Our Advantages

Complete fruit and vegetables turnkey processing project:

1、Original juice and paste processing line:Tomato, blueberry, apple, pear, mango, dragonfruit and passionfruit etc.

2、NFC juice concentrate juice processing line:Orange, apple, pear, peach, wolfberry, purple sweet potato, carrot, guava and litchi etc.

3、Dried fruit processing line:apple, pear, mango, durian, blueberry and kiwi etc.

4、Fruit wine, vinegar and fruit extractive processing line:apple, pear, blueberry, guava and litchi etc.

1、Original juice and paste processing line:Tomato, blueberry, apple, pear, mango, dragonfruit and passionfruit etc.

2、NFC juice concentrate juice processing line:Orange, apple, pear, peach, wolfberry, purple sweet potato, carrot, guava and litchi etc.

3、Dried fruit processing line:apple, pear, mango, durian, blueberry and kiwi etc.

4、Fruit wine, vinegar and fruit extractive processing line:apple, pear, blueberry, guava and litchi etc.

Kind

Reminder to customers:

Our company is capable to design a processing line with capacity 5T-1000T per day.

please kindly understand that the production line is a highly customized product.

The machine will be varied based on the automation degree and the final products type you want to get.

Therefore, If you need a quotation proposal from us, please contact our staff and offer the

following data to serve you better:

1.Is this your project "new project", "expansion project" or "transformation project"?

2.When and where you want to start this project?

3.What's the estimated capacity? Namely,how many raw material will be processed hourly?

4.What packaging of the end products?

Hot Searches