- Product Details

- {{item.text}}

Quick Details

-

Output Speed:

-

186 Rpm

-

Weight (KG):

-

3000

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

WL

-

Item:

-

Planetary Worm Gearbox

-

Steel Type:

-

Alloy & Carbon

-

Chemical Control:

-

Spectrograph

-

Defect Control:

-

UT, MT

-

Heat Treatment:

-

Anneal, Quenchining & Tempering

-

Surface Treatment:

-

Grinding

-

Inspection:

-

Third Party Approved

-

Machining:

-

According to Drawings

-

Weight:

-

MAX 50 Ton

-

Certificate:

-

BV, ISO9001-2000

Quick Details

-

Gearing Arrangement:

-

Worm

-

Output Torque:

-

350Nm

-

Input Speed:

-

1400rpm

-

Output Speed:

-

186 Rpm

-

Weight (KG):

-

3000

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

WL

-

Item:

-

Planetary Worm Gearbox

-

Steel Type:

-

Alloy & Carbon

-

Chemical Control:

-

Spectrograph

-

Defect Control:

-

UT, MT

-

Heat Treatment:

-

Anneal, Quenchining & Tempering

-

Surface Treatment:

-

Grinding

-

Inspection:

-

Third Party Approved

-

Machining:

-

According to Drawings

-

Weight:

-

MAX 50 Ton

-

Certificate:

-

BV, ISO9001-2000

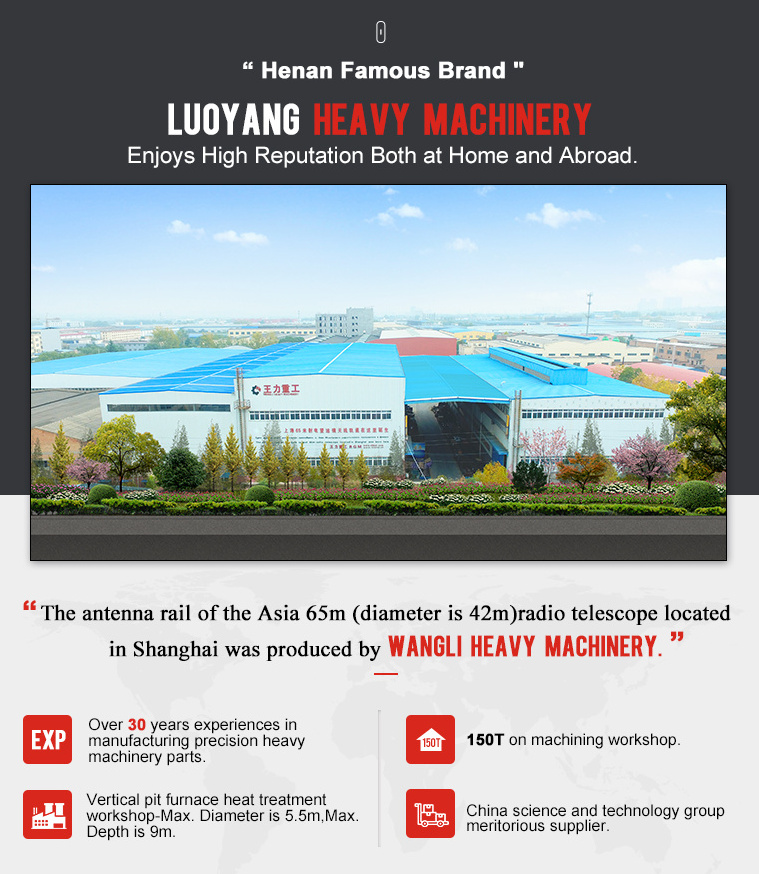

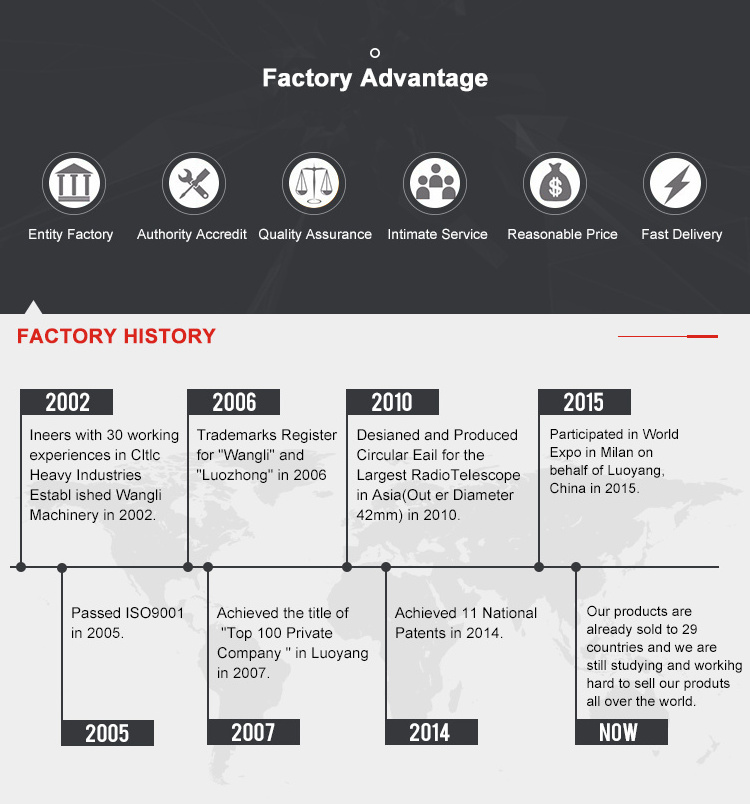

Our Company

Luoyang Wangli Heavy Machinery Co.,Ltd is High-Tech Enterprise, Luoyang Large Mold Heat Treatment Engineering Technology Center. The company has obtained more than 30 national patents, and its main products include spare parts for construction machinery (pull-shovel, electric shovel, driving), cement machinery spare parts, large modulus gear (shaft), hot forging die, large non-standard machinery products.

1. Over 30 years experiences in manufacturing precision large nonstandard heavy machinery spare parts.

2. Having five standardized workshops, which are hoisting hook 150 Tons.

3. Vertical well electric furnace heat treatment - Max. DIA is 6 meter, Max. Depth 9 meters.

4. Twelve senior engineers in forging/ heat treatment fields.

5. OEM & ODM can provided, specialized e-commerce and technical team can provide online service.

3. Vertical well electric furnace heat treatment - Max. DIA is 6 meter, Max. Depth 9 meters.

4. Twelve senior engineers in forging/ heat treatment fields.

5. OEM & ODM can provided, specialized e-commerce and technical team can provide online service.

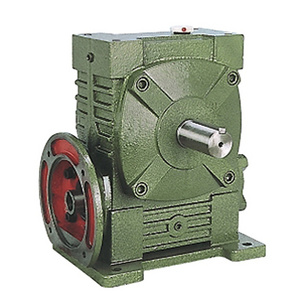

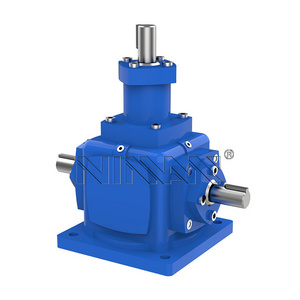

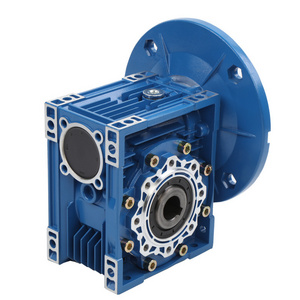

Products Show

High Quality Reduction Transmission large modulus Worm Gear box

/ speed reducer the application:

This is nonstandard gearbox, which is produced by drawings or customers' required. The max weight is 50 Tons per piece. Large mining excavator gearbox is used widely. Usually we produce the Large mining excavator gearbox according to the drawings. Meanwhile, we can design the Large mining excavator gearbox as the customers' required.

This is nonstandard gearbox, which is produced by drawings or customers' required. The max weight is 50 Tons per piece. Large mining excavator gearbox is used widely. Usually we produce the Large mining excavator gearbox according to the drawings. Meanwhile, we can design the Large mining excavator gearbox as the customers' required.

Inspection

Running Testing for

High Quality Reduction Transmission large modulus Worm Gear box

The running testing is top important for the gear box. This can test the precision and noise requirements. All our products should pass the quality test, then it can leave our company.

Diameter Checking

Outer Diameter is checked of

High Quality Reduction Transmission large modulus Worm Gear box

Packing & Delivery

The delivery of

High Quality Reduction Transmission large modulus Worm Gear box

usually use the steel frame and plywood bar to protect the important position. Do you have any good advice of it?

Our

High Quality Reduction Transmission large modulus Worm Gear box

have exported to thirty-eight countries in the world.

such as America, Australia, Russia, Pakistan, Thailand, Indian, Morocco, Romania, Spain,etc.

Advantage of our Heat Treatment:

- Professional, specific furnace, single-minded

- Vertical pit furnace,keep the temperature uniformity during heating,+/-1℃

-Small deformation,little oxide layer,reduce material cost

- Different materials can be cooled at the best speed

- Large capacity, completed variety of quenching medium: oil,water,salt water,water based mixture.

Machining

Completed Machining Equipment

We have the completed machining equipment,including horizontal lathe,vertical lathe,CNC boring and milling machine,CNC boring machine,deep hole drilling and boring machine,gear hobbing machine, gear teeth grinding machine,grinding machine,etc.

We can provide technical support on new material, heat treatment and new manufacture process according customer’s working condition in order to improve lifespan of machinery parts. We have got a lot of patents on the spare parts of mill,cement rotarykiln, dragline excavator, rotor shafts and so on.

Hot Searches