- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

270*260*350*60mm

-

Weight:

-

3KG

-

Name:

-

manual oil press machine

-

Raw material:

-

walnut,sesame,tea seed,sunflower seed,peanut ect

-

Material:

-

Stainless Steel 304

-

Function:

-

Making Edible Oil

-

Color:

-

Custom-made

-

Advantage:

-

Energy Saving

-

Product capacity:

-

1-2kg/h

-

Package size:

-

42*8*32cm

-

Automatic Grade::

-

Manual

-

Product name:

-

Oli Press Machine

-

Certification:

-

CE ISO

Quick Details

-

Production Capacity:

-

98%-100%

-

Place of Origin:

-

China

-

Brand Name:

-

Kinetic

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

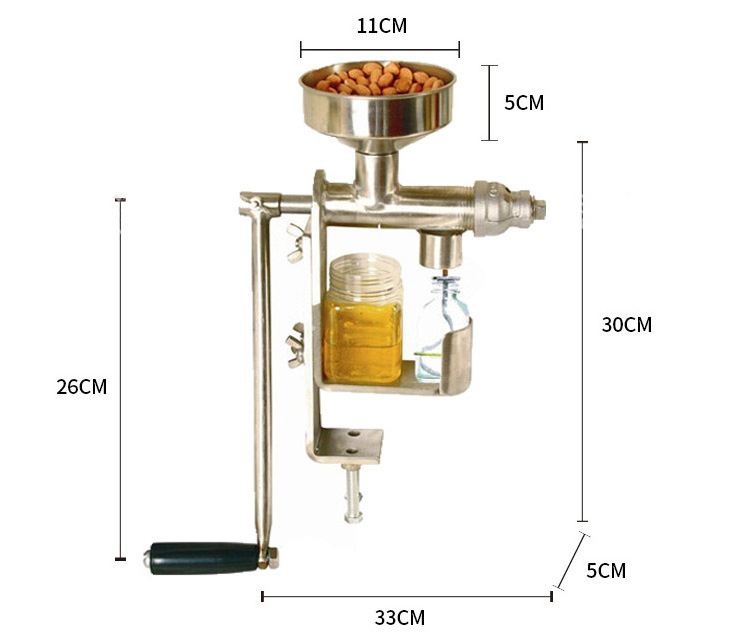

270*260*350*60mm

-

Weight:

-

3KG

-

Name:

-

manual oil press machine

-

Raw material:

-

walnut,sesame,tea seed,sunflower seed,peanut ect

-

Material:

-

Stainless Steel 304

-

Function:

-

Making Edible Oil

-

Color:

-

Custom-made

-

Advantage:

-

Energy Saving

-

Product capacity:

-

1-2kg/h

-

Package size:

-

42*8*32cm

-

Automatic Grade::

-

Manual

-

Product name:

-

Oli Press Machine

-

Certification:

-

CE ISO

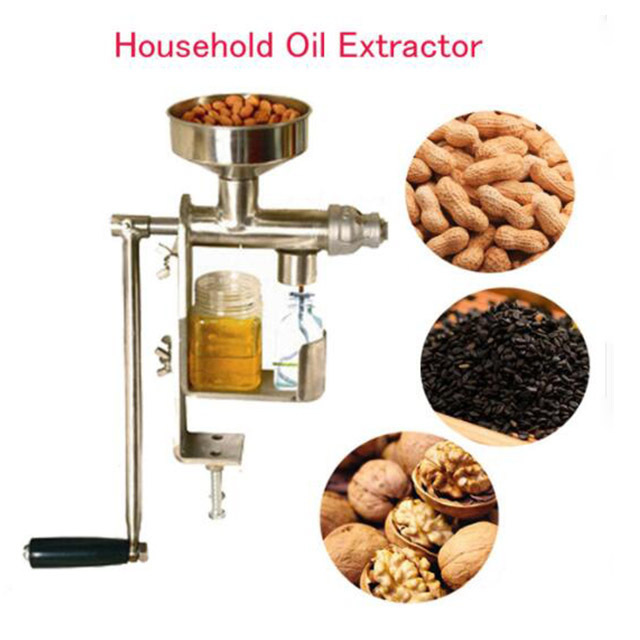

Manual cold oil press machine small olive oil press manual

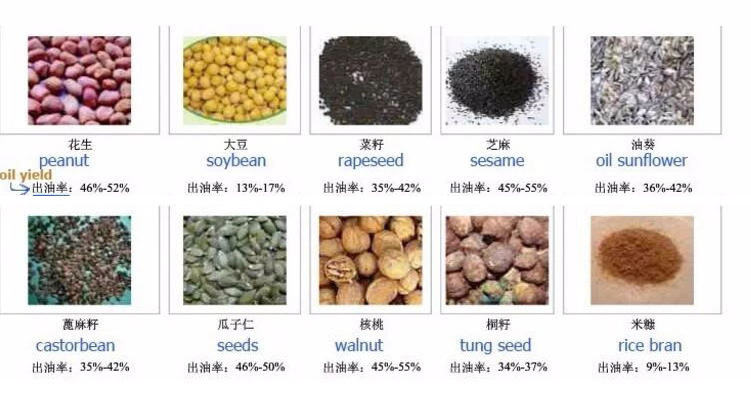

Product application of manual oil press machine:

Suitable for most oil crops with oil content more than 25%, such as peanuts, sunflower seeds, rapeseed, sesame, walnut kernels, etc.

|

Product name |

M anual oil press machine |

|

material |

S tainless steel 304 |

|

weight |

3 KG |

|

R aw material |

peanut,sesame,sunflower,soybean ,walnut ,etc |

|

power |

manual |

|

main parts |

frame,press cage,screw shaft,crank ,etc |

|

P acking size |

270*260*350*60mm |

|

color |

red or at your request |

Products display

Product details

Components of manual oil extractor

This machine consists of frame, press part, driver part and heating part etc. In view of environmental protection and recycling, material feeding/collecting equipment can be replaced with drink bottle, which is prepared by buyer.

Assembly of manual oil extractor

Before operation please fix the frame and make sure crank can be turned freely.

Lubricate washer with edible oil and insert on screw shaft from the small end.

Insert screw shaft in press cage.

Screw on press cage cap and screw on terminal adjustment bolt.

Attach crank arm to screw shaft and tighten the bolt.

Fill 80% fuel to the lamp bottle (kerosene or alcohol). Pass a 15cm wick through the washer. Leave 0.5cm of wick outside and put the longer end in the fuel bottle. Place washer at the bottle mouth. Place the lamp under press cage. Secure the lamp with rubber band.

It is very convenient

Operation of manual oil extractor :

Make sure no impurities in the material before pressing.

At the beginning of pressing, oil flowing from the terminal adjustment bolt is normal.

Loose the terminal adjustment bolt if the discharged cake is too dry and crank turning resistance is too big

Tighten the terminal adjustment bolt if the discharged cake contains too much oil residual.

Heating of manual oil extractor :

To guarantee the oil output, the press cage should be heated for about 10 minutes. when the press cage temperature reaches 50-70°C, material can be put into inlet for pressing. The lamp remains heating during pressing as well.

Cleaning of manual small oil press :

Clean the oil press immediately after operation. Otherwise residual in the machine will get hard and affect next operation.

Packing and delivering

Packing : inside: foam interior,each part is warm wrapped to ensure no damage

Exterior:neutral color box

Transport package:5sets/box 5 layers of cowhide corrugated paper

Single package:package with 2 layers of air bubble film and express bag