- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

1-2.5mm

-

Place of Origin:

-

HEB

-

Brand Name:

-

JCX

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

about 14.2*1.3*1.2m

-

Weight:

-

9500 kg

-

Feeding width:

-

according to profile drawing

-

Raw material:

-

Galvanized Steel Sheet

-

Application:

-

solar panel system

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Cutting blade material:

-

Cr 12Mov Processing

-

Roller material:

-

Gcr15 Bearing Steel

-

Cutting type:

-

Hydraulic or Flying Saw

-

Size of C channel:

-

41mm*41mm; 41*72mm

-

Machine color:

-

Cusotmized

-

Main motor power:

-

22kw

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

1-2.5mm

-

Place of Origin:

-

HEB

-

Brand Name:

-

JCX

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

about 14.2*1.3*1.2m

-

Weight:

-

9500 kg

-

Feeding width:

-

according to profile drawing

-

Raw material:

-

Galvanized Steel Sheet

-

Application:

-

solar panel system

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Cutting blade material:

-

Cr 12Mov Processing

-

Roller material:

-

Gcr15 Bearing Steel

-

Cutting type:

-

Hydraulic or Flying Saw

-

Size of C channel:

-

41mm*41mm; 41*72mm

-

Machine color:

-

Cusotmized

-

Main motor power:

-

22kw

Product Description

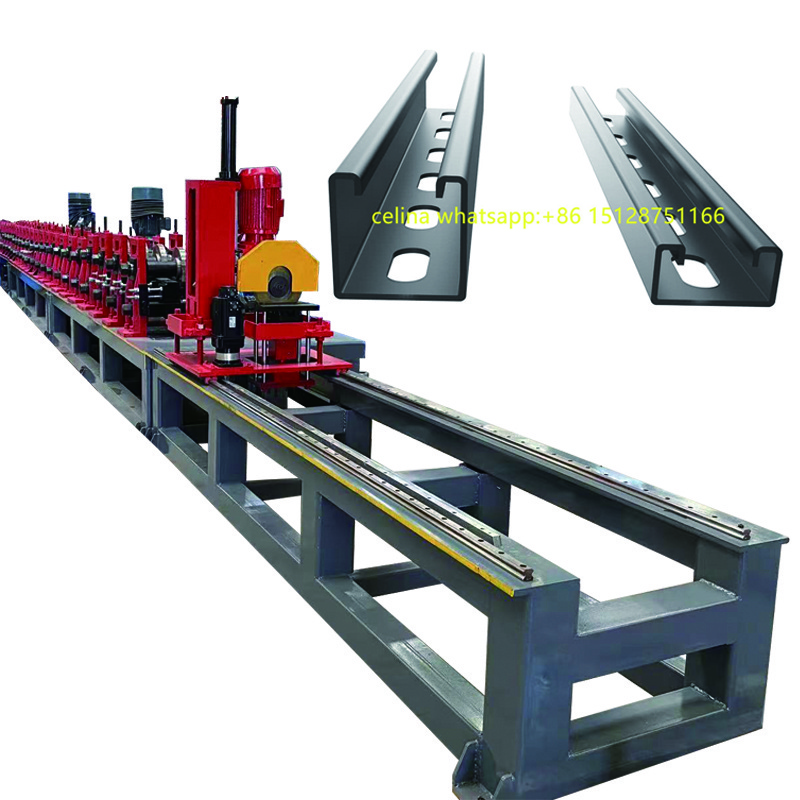

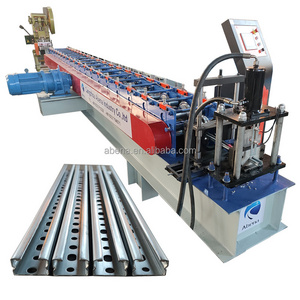

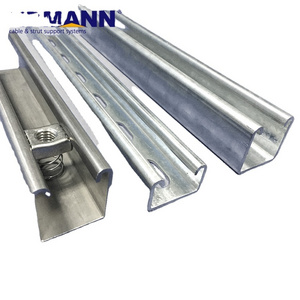

Solar photovoltaic bracket roll forming machine is a full automatic line to produce the solar photovoltaic bracket strut ,which is a special bracket designed for placing, installing and fixing solar panels in solar photovoltaic power generation system. General materials include aluminum alloy, carbon steel and stainless steel.The products related to solar support system are made of carbon steel and stainless steel. The surface of carbon steel is hot-dip galvanized and will not rust after 30 years of outdoor use. The solar photovoltaic support system is characterized by no welding, no drilling, 100% adjustable and 100% reusable

1. Suitable Material:

1) Material: Cold rolled coil, hot rolled coil, Galvanized Steel

2) Thickness of material: 2-3.5 mm

3) Strength of coil: Q195, 235B Mpa

2. Profile design of Solar photovoltaic bracket roll forming machine :

1) Material: Cold rolled coil, hot rolled coil, Galvanized Steel

2) Thickness of material: 2-3.5 mm

3) Strength of coil: Q195, 235B Mpa

2. Profile design of Solar photovoltaic bracket roll forming machine :

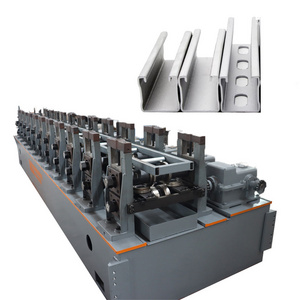

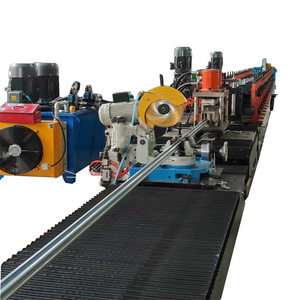

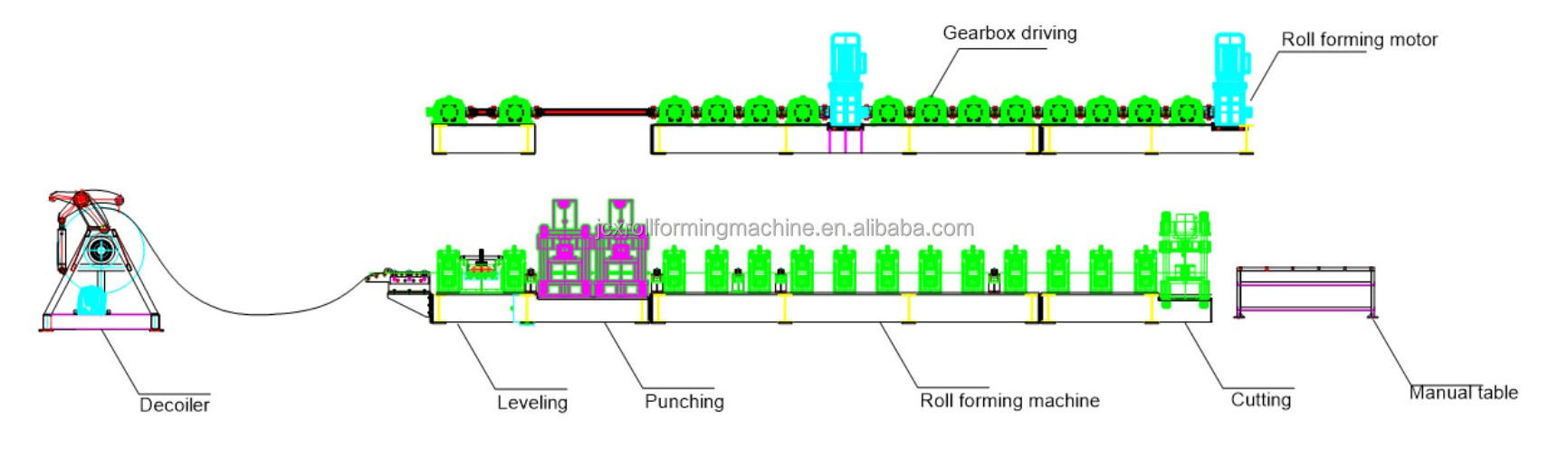

3. Component of

Solar photovoltaic bracket roll forming machine:

1. 10T hydraulic automatic decoiler-------1 SET

2. Main machine---------1 set

2.1. Guiding device,Levelling part

2.2. Two sets of pre-punching part

2.3. Forming system

2.4. Gearbox Transmission system

2.5. Hydraulic guillotine

2.6. Hydraulic pump station.

3. Control box ---1 SET

1. 10T hydraulic automatic decoiler-------1 SET

2. Main machine---------1 set

2.1. Guiding device,Levelling part

2.2. Two sets of pre-punching part

2.3. Forming system

2.4. Gearbox Transmission system

2.5. Hydraulic guillotine

2.6. Hydraulic pump station.

3. Control box ---1 SET

Technical Parameters of Solar Panel Strut Channel Machinery Unistrut C Channel photovoltaic support roll forming machine

1. Material thickness range:1.5-2.5mm,feeding width: 90-230mm

2. Main motor power: 22 k w

3. Forming speed:8 m/min

4. Shearing method: Hydraulic shearing.

5. Hydraulic station power:11 KW

6. Quantity of rollers:24 rollers

7. Shaft Material and diameter: 80 mm, material is 45# forge steel

8.Material Of machine body: 25mm 45# steel

9.Tolerance: +-1.5mm

10. Transmission method: By double chains

11.Material of forming rollers: GCR15 steel, coated with chromed treatment

12.Material of cutter blade: Cr 12 mould steel with quenched treatment 58-62℃

13.Voltage: 380V/ 3phase/ 50 Hz (as request)

2. Main motor power: 22 k w

3. Forming speed:8 m/min

4. Shearing method: Hydraulic shearing.

5. Hydraulic station power:11 KW

6. Quantity of rollers:24 rollers

7. Shaft Material and diameter: 80 mm, material is 45# forge steel

8.Material Of machine body: 25mm 45# steel

9.Tolerance: +-1.5mm

10. Transmission method: By double chains

11.Material of forming rollers: GCR15 steel, coated with chromed treatment

12.Material of cutter blade: Cr 12 mould steel with quenched treatment 58-62℃

13.Voltage: 380V/ 3phase/ 50 Hz (as request)

Details Images

Hydraulic decoiler

Main Forming Machine (Gearbox drive)

Cutting system

Servo Motor No-Stop Hydraulic Cutting

Burr-free flying saw cutting

Auto Double Line Punching Machine

Packing & Delivery

Sea worthy standard package: covered with plastic film, fixed into 2*40'gp container

Hot Searches