- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v/220/Customized

-

Power:

-

150 kw

-

Weight:

-

80000 KG

-

Dimension(L*W*H):

-

30000*16000*20000 mm

-

Year:

-

2022

-

Application:

-

Fruit Vegetable

-

Advantage:

-

Low Consumption High Efficiency

-

Material:

-

304 Stainless Steel

-

Processing Types:

-

Vegetable Fruit Process Equpiment

-

MOQ:

-

1 Set

-

Final product:

-

Fruit Jam/juice

-

Capacity:

-

6.5 tons/h

-

Color:

-

Silver

-

After-sales Service Provided:

-

Overseas Service Provided

-

Model:

-

Customized

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

SSS

-

Type:

-

juicer

-

Voltage:

-

380v/220/Customized

-

Power:

-

150 kw

-

Weight:

-

80000 KG

-

Dimension(L*W*H):

-

30000*16000*20000 mm

-

Year:

-

2022

-

Application:

-

Fruit Vegetable

-

Advantage:

-

Low Consumption High Efficiency

-

Material:

-

304 Stainless Steel

-

Processing Types:

-

Vegetable Fruit Process Equpiment

-

MOQ:

-

1 Set

-

Final product:

-

Fruit Jam/juice

-

Capacity:

-

6.5 tons/h

-

Color:

-

Silver

-

After-sales Service Provided:

-

Overseas Service Provided

-

Model:

-

Customized

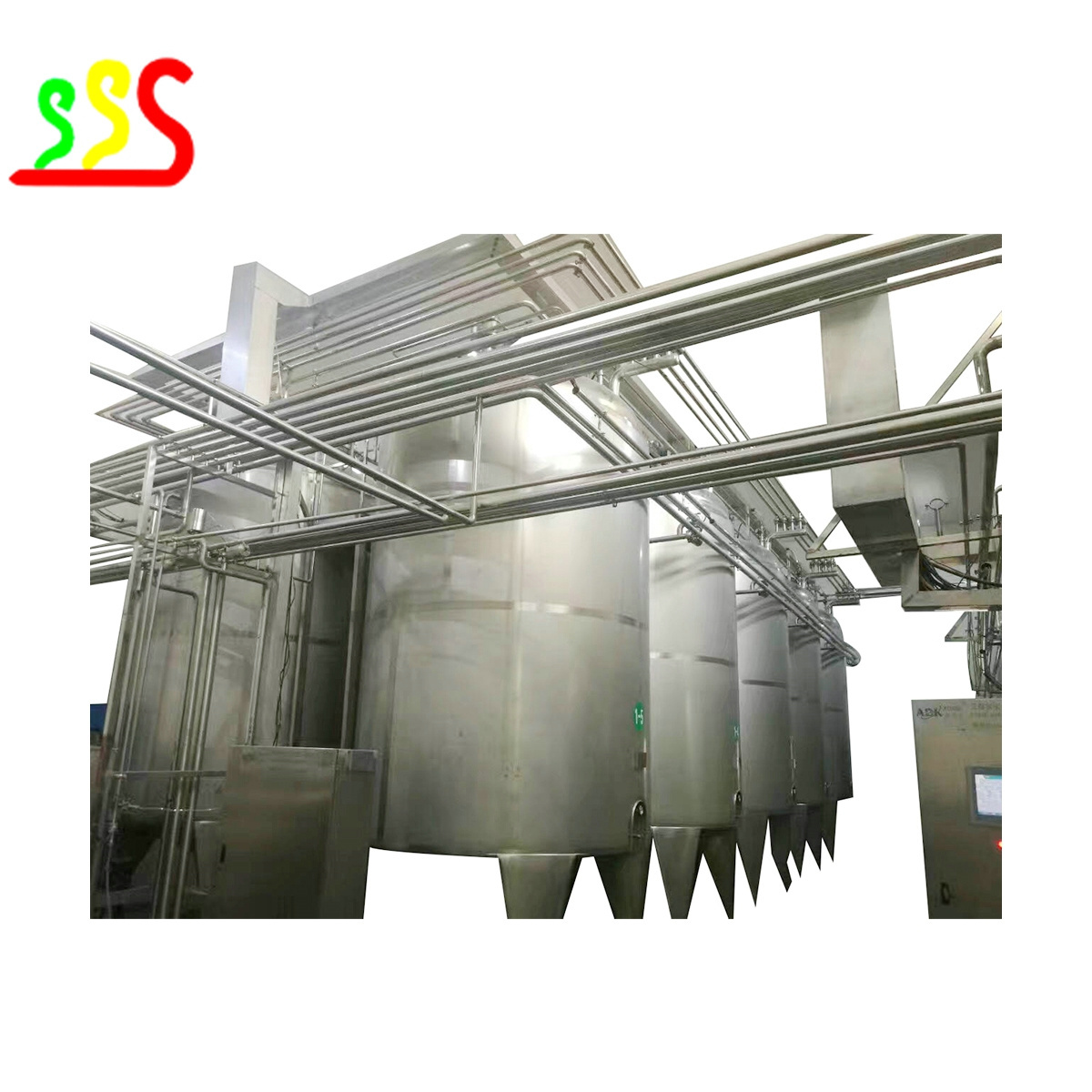

Product Description

SSS could provide all of the necessary apple/pear juice processing machine to achieve quality products at controlled cost.SSS belt-press extractor could help to produce good quality fruit/vegetable juice with high juice yield and low sediment content. An electronic monitoring and control system has been designed to make operation easy and reliable. SSS also offer comprehensive engineering services, installation supervision, commissioning support and operator training to help workers make proper operation with all the high-tech machines and to finish the complete fruit production.

Specification

|

no

|

item

|

specification

|

qty

|

|

B1

|

Fermentation tank

|

Ø Ø capacity: 5000L

Ø Ø liner thickness: 5mm; Ø Thickness of jacket coil plate: 2mm (SUS304); Ø Thickness of outsourcing: 3mm (SUS304); Ø The insulation layer is made of polyurethane foam Ø Ø SUS304 stainless steel; Ø Ø pulp stirring, motor, shaft, mounting seat; Ø Ø exterior surface adopts 2B plate; Ø Ø high and low level control; Ø Ø spherical head structure, including manhole, sterile air filter, cleaning ball, water inlet, steam inlet, material inlet and outlet, visual mirror, sampling valve, sterile breathing apparatus, circulation opening Ø Ø power: 5.5KW |

10

|

|

B2

|

Fermentation system platform

|

Ø Ø SUS304 stainless steel welding, main bracket 80*50 square tube, cross support adopts 40*40 square tube connection

Ø Ø SUS304 stainless steel non-slip plate 3mm thick, t-shaped Ø Ø length: 15 m *0.8 m * 3 m high |

2

|

|

B3

|

material pump

|

Ø Ø 1 t/h;

Ø Ø SUS304 material; Ø Ø Quantity: 1 set; Ø Ø lift 24m; Ø Ø stainless steel; Ø Ø power: 0.75kw; |

2

|

|

B4

|

Strain broadculture system

|

Ø Ø capacity: 200L

Ø Ø liner thickness: 3mm; Ø Thickness of jacket Miller plate: 2mm (SUS304); Ø Thickness of outsourcing: 1.5mm (SUS304); Ø The insulation layer is made of polyurethane foam, SUS304 stainless steel; Ø Ø pulp agitation, empty shaw; Ø Ø exterior surface adopts 2B plate; Ø Ø high and low level control; Ø Ø spherical head structure, including manhole, breathable cap, cleaning ball, water inlet, steam outlet, material inlet and outlet, visual mirror, sampling valve, sterile respirator, circulation outlet Ø Ø power: 1.1kW |

3

|

|

B5

|

The material of pump

|

Ø Ø 3 t/H.

Ø Ø SUS304 material; Ø Ø Quantity: 1 set; Ø Ø lift 24m; Ø Ø stainless steel; Ø Ø power: 1.1kw; |

3

|

|

B6

|

Buffer tank

|

Ø Ø Capacity: 1000L

Ø Ø SUS304 stainless steel; Ø Ø single-layer upper and lower cone bottom structure, with climbing ladder; Ø Ø exterior surface adopts 2B plate; Ø Ø high and low level control; Ø Ø cone top and cone bottom structure, including manhole, breathable cap, cleaning ball, water inlet and material inlet, Ø Ø inlet and outlet adopts anti-foam structure; |

2

|

|

B7

|

Screw material pump

|

Ø Ø output: 1T/h

Ø Ø mechanical seal with guide function; Ø Ø 304 stainless steel; Ø Ø outlet clamp connection; Ø Ø lift 60m; Ø Ø power: 0.75kW |

1

|

|

B8

|

Automatic diaphragm filter press

|

Ø Ø squeeze structure,

Ø Ø compressed air: 0.6-0.8mpa Ø Ø device is a carbon steel frame with 304 stainless steel cladding Ø Ø filter plate adopts food grade polypropylene material Ø Ø filter plate automatically draws; Ø Ø Filter pressure: 0.6mpa Ø Ø power: 6kw Ø Ø weight 3500 kg |

1

|

|

B9

|

Buffer tank

|

Ø Ø Capacity: 1000L

Ø Ø SUS304 stainless steel; Ø Ø single-layer upper and lower cone bottom structure, with climbing ladder; Ø Ø exterior surface adopts 2B plate; Ø Ø high and low level control; Ø Ø cone top and cone bottom structure, including manhole, breathable cap, cleaning ball, water inlet and material inlet, Ø Ø inlet and outlet adopts anti-foam structure; |

1

|

|

B10

|

Screw material pump

|

Ø Ø output: 1T/h

Ø Ø mechanical seal with guide function; Ø Ø 304 stainless steel; Outlet clamp connection; Ø Ø lift 60m; Ø Ø power: 1.1kW |

1

|

|

B11

|

The centrifuge

|

Ø Ø Material handling capacity: 1000-2000L/h

Ø Ø size: 1780mm*1475mm*1900mm Ø Ø drum speed: 6738rpm Ø Ø motor power: 15Kw (380V/ 3/50Hz) Ø Ø motor speed: 1460rpm Ø Ø launch time: 5-8 minutes Ø Ø stop time (without brake) : ≤40 minutes Ø Ø material inlet pressure: 0 ~ 0.1mpa Ø Ø outlet pressure: 0 ~ 0.3mpa Ø Ø operating water pressure: 0.2mpa ≤ P ≤ 0.45mpa Ø Ø operating noise: ≤76dB Ø Ø motor protection grade: IP54 Ø Ø motor insulation class: F Ø Ø Operation: 24-hour continuous operation |

1

|

|

B12

|

Buffer tank

|

Ø Ø Capacity: 1000L

Ø Ø SUS304 stainless steel; Ø Ø single-layer upper and lower cone bottom structure, with climbing ladder; Ø Ø exterior surface adopts 2B plate; Ø Ø high and low level control; Ø Ø cone top and cone bottom structure, including manhole, breathable cap, cleaning ball, water inlet and material inlet, Ø Ø inlet and outlet adopts anti-foam structure; |

1

|

|

B13

|

The material of pump

|

Ø Ø 3 t/H.

Ø Ø SUS304 material; Ø Ø Quantity: 1 set; Ø Ø lift 24m; Ø Ø stainless steel; Ø Ø power: 1.1kw; |

1

|

|

B14

|

Slaking tank

|

Ø Ø capacity: 10000L

Ø Ø SUS304 stainless steel; Ø Ø single-layer upper and lower cone bottom structure, with climbing ladder; Ø Ø exterior surface adopts 2B plate; Ø Ø high and low level control; Ø Ø cone top and cone bottom structure, including manhole, breathable cap, cleaning ball, water inlet and material inlet, Ø Ø inlet and outlet adopts anti-foam structure; |

10

|

|

B15

|

The material of pump

|

Ø Ø 3 t/H.

Ø Ø SUS304 material; Ø Ø Quantity: 1 set; Ø Ø lift 24m; Ø Ø stainless steel; Ø Ø power: 1.1kw; |

1

|

|

B16

|

Sugar pan/accessories system

|

Ø Ø rated sugar capacity: 200L/ time;

Ø Ø adopts jacket square structure, the r-shaped arc around is over without dead corner, and the mixing is more uniform. Ø Ø sugar time: about 5-20min/ time, which is determined according to different material characteristics. Ø Ø operating frequency: 50Hz; Ø Set according to the system; Ø Ø high-speed agitation 2900rpm, Ø Ø power 5.5 KW. Ø Electrode type high and low liquid level alarm; |

2

|

|

B17

|

The material of pump

|

Ø Ø 1 t/H;

Ø Ø SUS304 material; Ø Ø Quantity: 1 set; Ø Ø lift 24m; Ø Ø stainless steel; Ø Ø power: 1.1kw; |

2

|

|

B18

|

Prepare pot

|

Ø Ø capacity: 500L Ø Ø liner thickness: 3mm; Ø Ø SUS304 stainless steel; Ø Ø pulp stirring; Ø Ø exterior surface adopts 2B plate; Ø Ø high and low level control; Ø Ø spherical head structure, including manhole, aseptic air filter, cleaning ball, water inlet, material inlet and outlet, visual mirror, sampling valve, breathable cap and circulation opening; Ø Ø power: 1.5kw; |

2

|

|

B19

|

platform

|

Ø Ø SUS304 rack

Ø Ø SUS304 stainless steel fence Ø Ø SUS304 stainless steel anti-sliding plate |

1

|

|

B20

|

Material pump

|

Ø Ø 1 t/H;

Ø Ø SUS304 material; Ø Ø Quantity: 1 set; Ø Ø lift 24m; Ø Ø stainless steel; Ø Ø power: 1.1kw; |

1

|

|

B21

|

UHT aseptic tube sterilizer

|

Ø Ø capacity: 0.3t /h

Ø Ø tube structure, specialized for sterilization of fruit juice; Ø Ø is manufactured using edker patent technology, a leading sterilizer for high viscosity materials in China. Ø This tube sterilizer is mainly composed of tube type (multi-tube) heat exchanger, stepless variable transmission pump, reholder, closed bucket, brazing plate heat exchanger, controller, etc.; Ø Ø equipment process is as follows: Ø Ø material inlet temperature: 30℃~50℃ Ø Ø outlet temperature of material :90℃ Ø Ø sterilization temperature 110℃~131℃ adjustable Ø Ø sterilization time: 10s Ø Ø cooling water temperature: < Ø 18 ℃ Ø Ø system main characteristics are as follows: Ø Ø cooling water consumption :20 t/h, the water temperature is less than 18 ℃; Ø Ø steam consumption :500KG/H; Ø Ø compressed air :0.6m3/min; Ø Ø installed capacity: 3.3kW; Ø Ø system pressure: about 5bar; Ø Ø material pump a group, the speed is adjustable; Ø Ø CIP pump; Ø Ø A hot water pump; Ø Ø front material buffer tank with agitation Ø Ø related connection is protected by steam shielding Ø Ø hot water brazing heating plate, airtight water tank type |

1

|

|

B22

|

Glass bottle differential feeding machine

|

Ø Ø size: 2000*1000*850mm

Ø Ø motor power: 0.37kW Ø Ø delivery panel: plastic steel panel |

1

|

|

B23

|

Bottle washer

|

Ø Ø bottle size: 300-750ml

Ø Ø voltage: 380V 50Hz Ø Ø production capacity: 2000-3000 bottles/hour Ø Ø Power: 2.5kW Ø Ø consumption: 0.5 m3 / min Ø Ø air source: 0.6-08mpa Ø Ø water source pressure: 0.2-0.3mpa Ø Ø water consumption: 0.5-1 t/h Ø Ø exterior size :2000*1300*1750mm |

1

|

|

B24

|

Far infrared dryer

|

1Ø Ø Capacity: 2000 bottles/hour (adjustable speed)

Ø Ø the electric heating element uses a high quality opalescent quartz glass tube as the heating element, which has high radiation coefficient, low energy consumption, temperature range of 50-300℃. Aluminum silicate fiber is used as the heat preservation material in addition to the frame. The heat preservation performance is good Ø Ø control requirement: A synchronous power regulation method is used to achieve constant temperature, and the temperature is uniform and reliable. Ø All mechanical and electrical gas control using PLC as the control core, digital temperature controller temperature control, frequency conversion stepless speed regulation. Ø After setting the temperature in the oven, it can be automatically controlled by the system. The oven needs three temperature zones: initial temperature, high temperature and cooling. Ø Ø tunnel inlet and outlet to the filling machine (closed delivery) is protected by purifying air, forming an air curtain at the tunnel opening to prevent air pollution from the outside. The bottle is dried through the oven and has no residue. Ø Ø material: ALL adopt SUS304 stainless steel. Ø Ø oven box is insulated and the surface temperature of the equipment is operated below 40℃ Ø Ø heating temperature: ambient temperature -300 ° C (temperature adjustable, controllable) Ø Ø electrical source: 380V / 50Hz Ø Ø heating power: 30kW Ø Ø motor power: 2.2kW Ø Ø size: 9600*700*1500mm |

1

|

|

B25

|

Bottle cap disinfection cabinet

|

Ø Ø uses ultraviolet disinfection

|

1

|

|

B26

|

Filling machine

|

Ø Ø filling specification: 300-750ml

Ø Ø filling speed: 300-500 bottles/hour (30ml); Ø Voltage and power: 220V / 50Hz. Ø 2-2.0 kw Ø Ø air source pressure:.4-0.6mpa Ø Ø size: 2500*1300*1800mm Weight :820kg, voltage: AC220v/50HZ Ø Ø pressure: 0.4-0.6mpa |

1

|

|

B27

|

Automatic cap fixing and capping machine

|

Ø Ø cap reverse cap automatic elimination, the cap no aluminum foil or screw defective product;

Ø Digital display adjustment mechanism; Ø Ø touch screen, an operating system which is displayed in Chinese dynamic graphics as a man-machine interface, on which the maneuvering parameters can be set or adjusted; Ø Ø stepped lid, noiseless, the lid is delivered into the capping track, and is removed automatically if the direction is different. Ø The outer surface parts of the machine are made of stainless steel AISI 304, which meet the requirements of GMP Ø Ø consumption: 300L/min Ø Ø top speed: 300-500b /h Ø Ø electrical source: 220V,50Hz Ø Ø bottle cap: ø 15 ~ ø 70 Ø Ø Total power: 1.25kW Ø Ø bottle diameter: ø 20 ~ ø 100mm Ø Ø dimensions: 1430 x 900 x 2141 Ø Ø air pressure: 0.5 ~ 0.7mpa |

1

|

|

B28

|

Oral liquid filling and sealing machine

|

Ø Ø the machine is a liquid filling and capping device for glass bottles.

Ø Filling for plunger pump, metering is divided into two levels of adjustment -- coarse and fine adjustment, double drainage filling; Ø Filling control adopts stainless steel check valve, good sealing performance, to ensure no drip phenomenon; Ø Screw bottle, six head rolling cover, rolling cover for four knife type, two knife rolling along, two knife rolling thread; Ø PLC control, touch screen operation, no bottle no filling, no lid alarm and other functions, make the equipment more perfect. Ø Ø Main technical parameters Ø Ø production capacity: 1000-2000 bottles/hour Ø Ø applicable bottle: a 50ml glass bottle Ø Ø number of cans: four Ø Ø loading error: 0 ~ 2% Ø Ø rolled caps: 1 Ø Ø lock: roll the anti-theft cap Ø Ø power rate: 2Kw Ø Ø size: 3400 x 900 x 1650 |

1

|

|

B29

|

Spray sterilizer

|

Ø Ø working principle: The product is heated and insulated online for 15 minutes, and sprayed

Ø Ø three-section cooling for 15 minutes, the last section is washed with softened water. Ø After a period of Ø Ø cold water circulation to the front section after use exits from the front section outlet and cools the temperature from < 85℃ to > 40℃±5 ℃. Ø design features: PLC controller, touch screen operation interface. Ø drop Ø Ø warm water adopts cooling tower water, which is supplied by automatic flushing water supply Ø Ø surplus water overflows. Ø Ø material standard: Stainless steel is used in spray device, waterway and pipeline Ø Ø manufacture, water pump according to actual functional requirements. Ø Pump brand: control Ø Ø system adopts button control. |

1

|

|

B30

|

Blow drying machine

|

Ø Ø uses high pressure and large flow fan to generate strong wind, the wind flows out of the long slit in the shaan, the wind

knife is made into an oblique shape, and the bottle passes through the knife to blow off the obvious water droplets on the surface of the bottle, facilitating the operation of the following procedure. Ø Ø Machine is applied to remove water from sterilized packaging bags in food, beverage, pharmaceutical and other industries. The Ø machine provides a variety of functions that are unavailable to other devices. Ø The machine does not use auxiliary heating, greatly saving energy, reducing costs, improve work efficiency. |

1

|

|

B31

|

Self-adhesive labeling machine

|

Ø Ø voltage specification: 220V/50/HZ/ 300W

Ø Ø size: 2000 (L) ×700 (W) ×1270 (H) mm Ø Ø labeling speed: 20-100 bottles /min (labeling speed: 3.5m/min)

Ø Ø Direction of material delivery: left to right

Ø Ø machine weight: 200KG Ø Ø labeling accuracy: ±1mm (excluding the error between the object and the label itself) Ø Ø apply bottle type: round bottle single-sided labeling; Ø . Ø Ø applicable container range: outer diameter 30-120 mm, height 35-300 mm Ø Ø applicable label range: 15-200mm in height, 23-300 mm in length Ø Ø Request on label volume: Ø Ø label base paper uses Glazine base paper (transparent base paper); Ø Ø label surface paper thickness is not less than 25×10-6m(25μm); Ø Ø label roll outer diameter < φ350; Ø The inner diameter of the label roll is φ76 |

1

|

|

B32

|

Solid bottle delivery chain system

|

Ø Ø chain plate 304 stainless steel water tray, lap type, thin wall bright stainless steel drain pipe ≥2 inches, wall thickness ≥

1.5mm Ø Ø frame is made of stainless steel, thickness 2.5mm, legs 304 stainless steel wire groove mounted on the side of delivery chain, 150W*100H and cover plate 30m |

30 m

|

|

B33

|

Conveyor motor

|

Ø Ø Domestic brand motor

|

5

|

|

B34

|

Spurt the code machine

|

Ø Ø British Lead

|

1

|

|

B35

|

The platform using the

|

Ø Ø single side closure, adjustable 304 stainless steel structure is not less than 2.5mm in thickness, 4M in length and 1.2m in

width |

1

|

|

B36

|

Automatic metering flowmeter

|

Ø Ø automatic metering

Ø Ø analog quantity 4-20mA output |

5

|

|

B37

|

Automatic electric control system for fermentation/filtration/curing

|

Ø Ø Siemens PLC, S7200, touch screen;

Ø Ø Schneider or Omron low-voltage electrical appliance, imported flow meter, PLC analog module, expansion module, Airtek solenoid valve, liquid level meter; Ø Ø cabinet adopts SUS304 stainless steel; Ø Ø implements the control of system material transfer, liquid level, signal conversion, etc. Ø Ø three phase five wire, 380V, 50Hz; |

1

|

|

B38

|

Deploy automatic electrical control system

|

Ø Ø Siemens PLC, S7200, touch screen;

Ø Ø Schneider or Omron low-voltage electrical appliance, flow meter, PLC analog module, expansion module, Airdecker solenoid valve, liquid level meter; Ø Ø cabinet adopts SUS304 stainless steel; Ø Ø button controls and emergency stop Ø Ø implements the control of system material transfer, liquid level, signal conversion, etc. Ø Ø three phase five wire, 380V, 50Hz; |

1

|

|

B39

|

Post packaging control system

|

Ø Ø Schneider or Siemens low voltage electrical Inventen converter

|

1

|

Packing & Delivery

WOODEN CASE

FAQ

1. who are we?

We are based in Anhui, China, start from 2013,sell to Domestic Market(30.00%),South America(15.00%),Eastern Europe(10.00%),Africa(10.00%),Mid East(10.00%),Northern Europe(10.00%),South Asia(10.00%),Southern Europe(5.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Tortilla Making Machine,Nail Making Machine,Food Machinery

4. why should you buy from us not from other suppliers?

We devote ourselves to research and develop the equipment including not only common types but also customized ones, our distinguished advantage is we can produce & design equipment as per your real situation and provide you with flexible solutions.

5. what services can we provide?

Accepted Delivery Terms: CFR,EXW;

Accepted Payment Currency:null;

Accepted Payment Type: T/T,L/C,D/P D/A,Credit Card,PayPal,Western Union;

Language Spoken:English,Chinese,Spanish,French,Russian

We are based in Anhui, China, start from 2013,sell to Domestic Market(30.00%),South America(15.00%),Eastern Europe(10.00%),Africa(10.00%),Mid East(10.00%),Northern Europe(10.00%),South Asia(10.00%),Southern Europe(5.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Tortilla Making Machine,Nail Making Machine,Food Machinery

4. why should you buy from us not from other suppliers?

We devote ourselves to research and develop the equipment including not only common types but also customized ones, our distinguished advantage is we can produce & design equipment as per your real situation and provide you with flexible solutions.

5. what services can we provide?

Accepted Delivery Terms: CFR,EXW;

Accepted Payment Currency:null;

Accepted Payment Type: T/T,L/C,D/P D/A,Credit Card,PayPal,Western Union;

Language Spoken:English,Chinese,Spanish,French,Russian

Contact us

Hot Searches