- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

XSUPER

-

Model Number:

-

X203-PX8

-

Warranty:

-

12 Months

-

Rim Clamping:

-

10''-24''

-

Max. Wheel Diameter:

-

1000 mm (39")

-

Max. Wheel Width:

-

340 mm (13")

-

Bead-Breaker Cylinder Force at 10 Bar:

-

3000 kg

-

Max. Inflating Pressure:

-

3.5 bar (50 psi)

-

Max. spindle torque:

-

1200 Nm

-

Net Weight:

-

200kg

-

Gross Weight:

-

233 kg

-

Packing Dimension:

-

970 x 760x940mm

Quick Details

-

Motor Power:

-

0.55kw/0.75kw

-

Operating Pressure:

-

10 bar (140 psi), 10 bar (140 psi)

-

Power Supply:

-

AC110V/220V/380V/50~60Hz

-

Place of Origin:

-

China

-

Brand Name:

-

XSUPER

-

Model Number:

-

X203-PX8

-

Warranty:

-

12 Months

-

Rim Clamping:

-

10''-24''

-

Max. Wheel Diameter:

-

1000 mm (39")

-

Max. Wheel Width:

-

340 mm (13")

-

Bead-Breaker Cylinder Force at 10 Bar:

-

3000 kg

-

Max. Inflating Pressure:

-

3.5 bar (50 psi)

-

Max. spindle torque:

-

1200 Nm

-

Net Weight:

-

200kg

-

Gross Weight:

-

233 kg

-

Packing Dimension:

-

970 x 760x940mm

Products Description

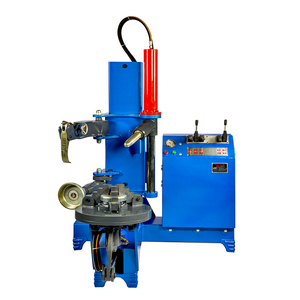

X203-PX8 Pneumatic Tire Changer for sales

2019 popular selling stars with super-sized cylinders

|

Specifications

|

|

|

|

Rim Clamping

|

10''-24''

|

|

|

Max. Wheel Diameter

|

1000 mm (39")

|

|

|

Max. Wheel Width

|

340 mm (13")

|

|

|

Bead-Breaker Cylinder Force at 10 Bar

|

3000 kg

|

|

|

Operating Pressure

|

10 bar (140 psi)

|

|

|

Power Supply

|

AC110V/220V/380V/50~60Hz

|

|

|

Motor Power

|

0.55kw/0.75kw

|

|

|

Max. Inflating Pressure

|

3.5 bar (50 psi)

|

|

|

Max. spindle torque

|

1200 Nm

|

|

|

Gross Weight

|

233 kg

|

|

|

Packing Dimension

|

970 x 760 x940mm

|

|

Details Images

Mounting head

made of high strength alloy steel , wear-resistance and corrosion-resistance

Two-speed motor

Precise and high torque at low speed for the best mouting and demouting result

Special clamp

The clamp is made of special material , strong and durable , also with plastic protective cover

Foot control pedal

With micro-control function provides precise clamping , avoiding damage to the rims

Accessories & Parts

You May Like

Why Choose Us

Lawrence is a manufacturer specializing in tyre service equipment over 15 years .The products cover 4 series and 5 categories, which can meet the requirements for different target users including OEM manufacturer, workshops, tyre shops, etc.We focus on user experience, and with a sophisticated technology R&D team . And we have established perfect technical support and after-sales guarantee system to support our customers .The Technical timeline of Lawrence are as below:

•2004, Lawrence developed CCD wheel aligner with 3-Dimensional Operating System.

•2005, Lawrence developed Drive-on Camera Aid function (First one in China) and Voice Prompt function.

•2007, Lawrence developed V3D wheel alignment and started to mass production.

•2008, Lawrence developed T Form Fully Intelligent Lifting System (IAA) in V3D wheel alignment.

•2009, Lawrence added Jack-Up Adjustment function in V3D wheel alignment.

•2010, Lawrence developed Android Pad Synchronous Display system (First one in the world).

•2011, Lawrence developed Hand recognition Function (Patent).

•2011, Lawrence developed 3D wheel aligner CUBE10 with two columns, supporting pit test and adjustment.

•2012, Lawrence developed SMART TOE (like Win Toe) and Engine Cradle Adjustment function

•2013, Lawrence started to use 5 Megapixel industry cameras for wheel alignment

•2014, Lawrence started to use Black Mini Target for wheel alignment

•2015, Magic Tyre changer X618 came out

•2016, Laser wheel balancer B805 came out

•2017, Lawrence developed Ride Height function in 3D wheel alignment

•2018, Auto Brake wheel balancer came out

•2018, Touchless wheel clamp and 6.4 Megapixel industry cameras both came out.

•2019, kUPER 3D wheel alignment came out

Factory veiw

FAQ

Q: Can computer and camera beam be installed in different room ?

A: Yes.We will provide different install solution according to your workshop condition.

Q:Cane we use 380V/50HZ as power supply ?

A:Yes,additional cost needed .

Q:Can you install wheel on cabinet make the machine movable?

A:Yes,but it's only valid on 8s and 708 model.

Q: How to update the database?

A:Freely whole life through online .

Q:Can you customize logo, color, interface on cabinet and software interface?

A:Yes.As long as the LOGO function for your request if you want to add or remove any function and database bank can be yours name also.

Q:Can I be exclusive representative?

A:We are looking for long term exclusive distributor except in Brazil ,India, South Africa, Pakistan, Malaysia. Welcome to join Lawrence!

Q:Can I buy wheel aligner kit ?

A:Yes ,but please be noted that our software can only operated with our own target plates and cameras.

Q:Can I get 2 years warranty or longer warranty ?

A:We offer 1 year warranty for free.2 year warranty with extra money.

Q:Can I pay in RMB currency?

A:Yes, but we need to add extra 20% based on the current price. Because we need to pay more tax ,so we suggest you pay in US dollars.

Q:How to calibrate the camera and target plates ?

A:For camera ,useless they are totally destroyed or crashed to deformation .They don't need calibration. Camera calibration need calibration bar. Target plates calibration is simple .The calibration finished in few minutes, following software instruction.

Q:Do I need to Re-Calibrate after equipment arrived and installed ?

A:No need, we already calibration well in factory before departure.

Q:Where Calibration Data Your Battle-Axe Designed ?

A:Inside of camera processor instead of inside software ,this design will save after service time for customer when their computer break

Q:What is delievery time ?

A:2 working days upon receiption of down payment .

Q:Could you send me a demo software ?

A:Yes. Contact us for download linkage.

Q:Could you translate the software language to our native language ?

A:We already have Spanish, English ,Portuguese, Japanese and Chinese language .If you need other language we can add it for you ,or you can help us transfer(we prefer this way ), We will offer you discount as your efforts .

Q:How to installation ?

A:Through video show training.

Q:How long is the lifetime of the machine ?

A:At least ten years, under good preservation .

Chat Now !

Hot Searches