- Product Details

- {{item.text}}

Quick Details

-

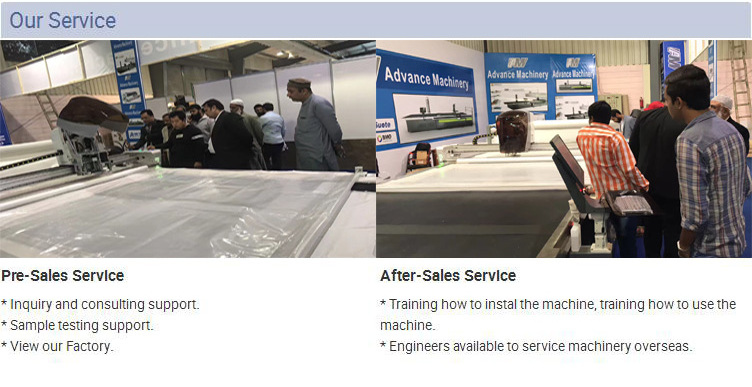

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Online support, Field installation, commissioning and training, Field maintenance and repair service

-

Application:

-

Fabric

-

spreading height:

-

250mm

-

Power supply:

-

220V-240VAC/110VAC 50HZ/60HZ

-

Key words:

-

Garment Spreading Machine

-

Function:

-

auto cutting

-

width:

-

1.6/1.9/2.1/2.6/3.0m

-

diameter of roll:

-

600mm

-

speed max.:

-

95m/min

-

optional function:

-

auto ram device

Quick Details

-

Marketing Type:

-

spreading machine with cutting tables

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

YINENG TECH

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Online support, Field installation, commissioning and training, Field maintenance and repair service

-

Application:

-

Fabric

-

spreading height:

-

250mm

-

Power supply:

-

220V-240VAC/110VAC 50HZ/60HZ

-

Key words:

-

Garment Spreading Machine

-

Function:

-

auto cutting

-

width:

-

1.6/1.9/2.1/2.6/3.0m

-

diameter of roll:

-

600mm

-

speed max.:

-

95m/min

-

optional function:

-

auto ram device

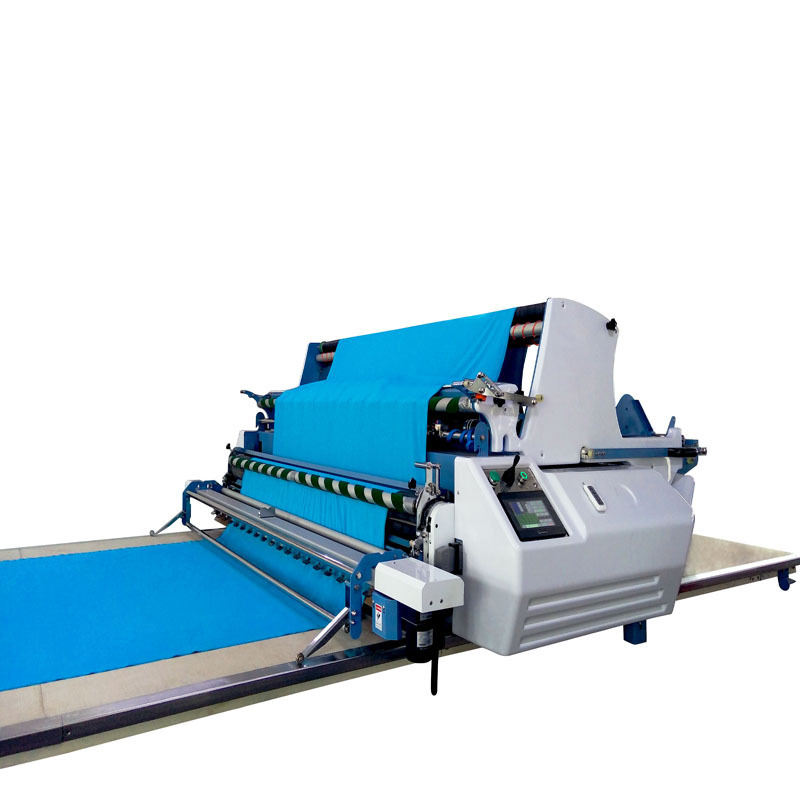

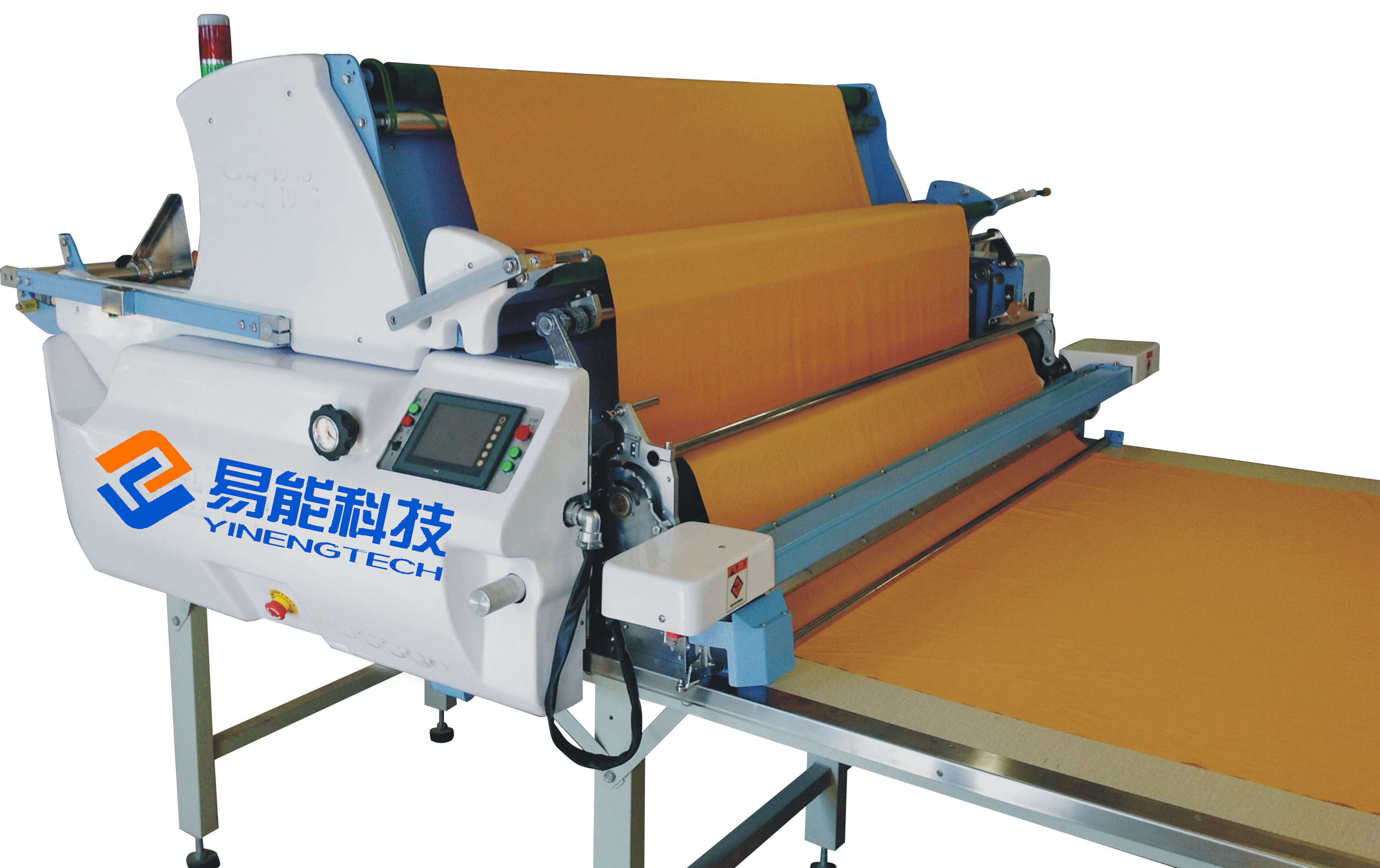

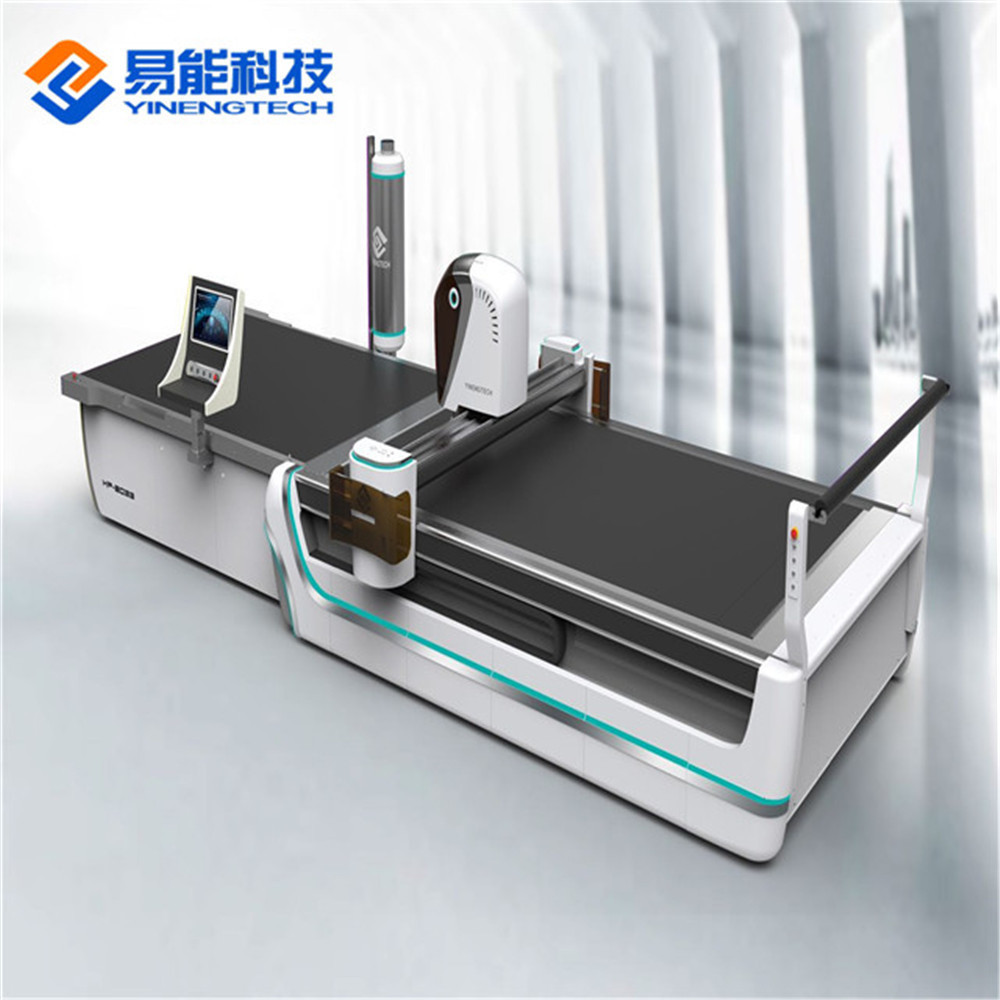

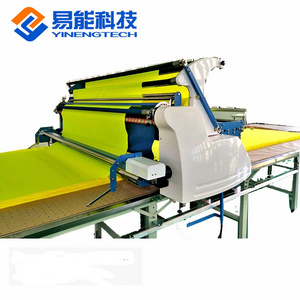

Automatic Spreading Machine With Cutting Tables For Cloth Cutting Spreading Machine

Features:

1. Adopt Taiwan imported PLC touch LCD screen operation system, easy and convenient to operate.

2 . Automatic spreading cloth system, cloth spreading very smoothly and non-tension spreading through roller conveyer belt. no pull and no size change to cloth

3. Double and single pull split structure

4. Automatic sharpening function and adjustable knife row distance

5. Automatic stop and return back to original position once cloth spreading finished.

6.

When any emergency brake happen, the machine won’t drag spread the cloth.

|

Model |

For woven/no-woven fabric |

Universal for both knitted and woven fabric |

||||||

|

KP -L 160 |

KP -L 190 |

KP -L 210 |

KP -L 160S |

KP -L 190S |

KP -L 210S |

|||

|

Voltage |

1P/220V |

|||||||

|

Motor power |

1KW |

|||||||

|

Diameter of cloth |

600mm max |

|||||||

|

Working speed |

95m/min max |

|||||||

|

Weight of machine |

550KG |

570KG |

590KG |

550KG |

570KG |

590KG |

||

|

Cloth Width (cm) |

16 0 |

190 |

210 |

16 0 |

190 |

210 |

||

|

Table Width(cm) |

183 |

213 |

233 |

183 |

213 |

233 |

||

|

Unit table length |

120cm |

120cm |

120cm |

120cm |

120cm |

120cm |

||

|

Total table quantity |

According to per client’s factory requirements on table total length, For example: required table quantity is total length / 1.2m/table. |

|||||||

Flotation table and electric rail:

1. Flotation table(special for spreading machine):

Every unit table is about 45KG, thickness 30mm, And the surface plate with 1MM thickness of the special laminate hard plastic sheet, the middle plate is pressed from 9cm high quality solid plate. Angle and bearing angle steel "70MM * 45MM * 2MM" are made of international standard materials. The air float cutting table is specially made on this basis. Every four cutting boards will be equipped with 2,2KW \ 380V three-phase fan motor to provide powerful wind power to make the cloth move easily.

Electric rail:

It is equipped with Panasonic “ DH6133 ” track made in Japan, which has the advantages of safety, beauty and long service life. It is also equipped with "DH6076" power supply pulley and "DH6172" into electrical appliances and end caps are made by Matsushita Electric Works of Japan original products.