- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Willow

-

Color:

-

Red/custom

-

Material:

-

SBR NBR NR EPDM Ect

-

Product Name:

-

Industrial Rubber Sheet

-

Application:

-

Industrial Rubber Slab

-

Thickness:

-

1-1000mm

-

Feature:

-

Wear Resistant

-

Hardness:

-

65+-5 ShoreA

-

Certification:

-

ISO CE

-

Surface:

-

Glossy

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

GUOJU

-

Model Number:

-

Willow

-

Color:

-

Red/custom

-

Material:

-

SBR NBR NR EPDM Ect

-

Product Name:

-

Industrial Rubber Sheet

-

Application:

-

Industrial Rubber Slab

-

Thickness:

-

1-1000mm

-

Feature:

-

Wear Resistant

-

Hardness:

-

65+-5 ShoreA

-

Certification:

-

ISO CE

-

Surface:

-

Glossy

Products Description

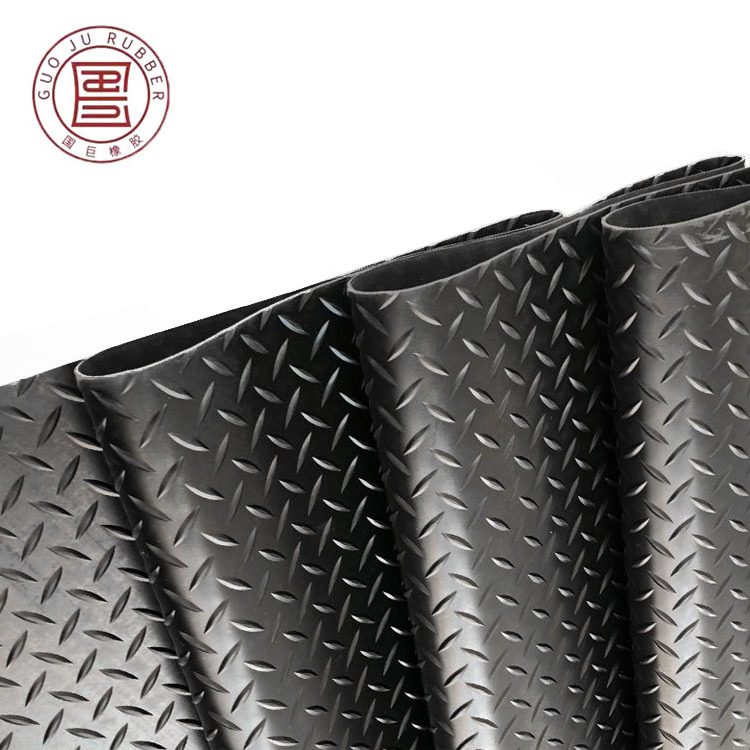

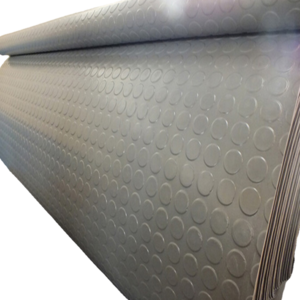

Natural rubber sheet-

Non-slip mat willow leaf pattern

Specification of natural rubber sheet :

(1) According to the voltage level can be divided into 5kv, 10kv, 20kv, 25kv, 35kv

(2) According to the color can be divided into: black rubber mat, red rubber mat, green rubber mat

(3) According to the thickness can be divided into: 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm.

Natural rubber sheet use scope and storage mode:

Widely used in substations, power plants, power distribution rooms, test rooms and field with electricity operations and other uses. It should be stored in a dry and ventilated environment, away from heat sources and more than 20cm from the ground and walls.

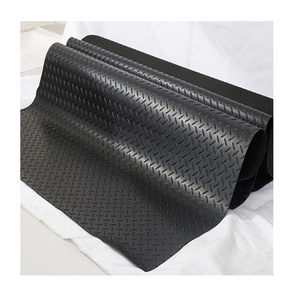

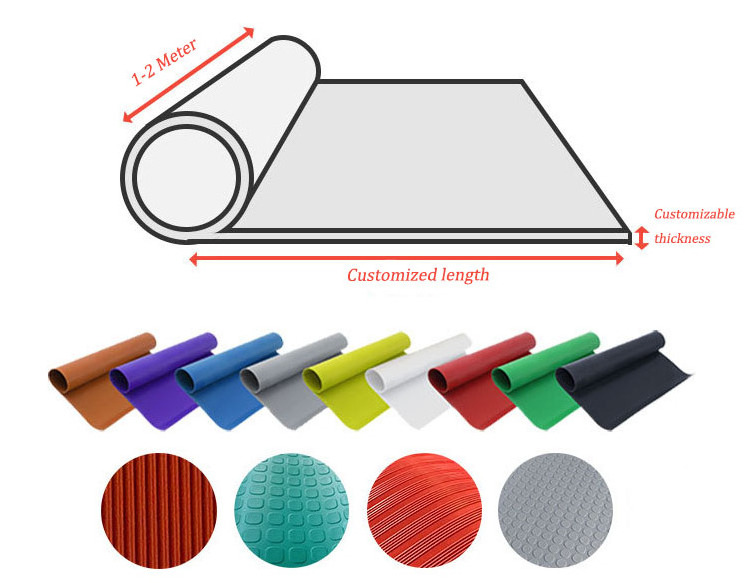

Product color: black, red, green (multi-color optional)

Thickness: 3MM, 5MM, 8MM, 10MM

Product voltage resistance: 6KV, 10KV, 25KV, 35KV

Product characteristics: insulation and anti-slip, wear-resistant pressure, waterproof and oil-proof, special for power distribution

Details Images

Natural rubber material

No irritating odor

High density

Long service life

Various specifications and color customization

Support OEM/ODM

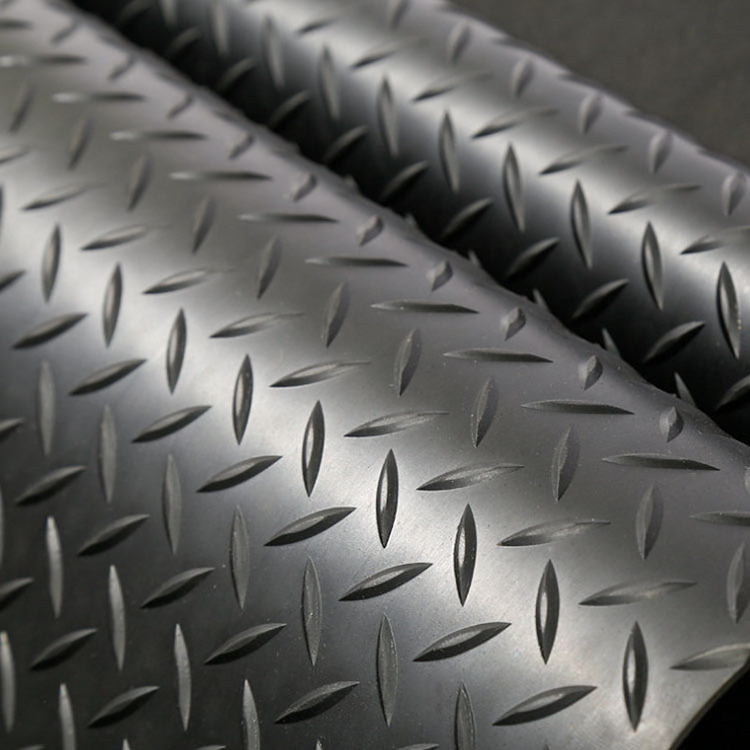

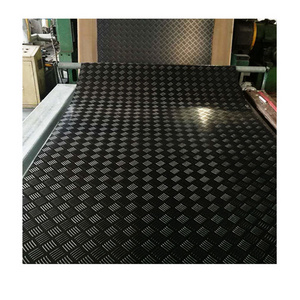

Positive round button pattern anti-slip by abrasion / corrosion and pressure resistance / insulation / aging resistance

Waterproof and anti-slip insulation by abrasion and pressure resistance by use.Even thickness, clear pattern

Anti-slip pattern on the reverse side is waterproof and non-slip / fits the surface of each working environment / suitable for floor and countertop

S

mooth surface

No bubbles

Soft and highly elastic

No crease when folded at will

Waterproof and oil resistant, good sealing effect, easy to wipe and clean, suitable for a variety of working environments

Product Paramenters

|

Types of glue board and technical parameters

|

|

|

|

|

|

|

|

|

||||||||

|

Type

|

Size

|

Width

(mm)

|

Anti-slip wire

|

Specific Gravity

|

Tensile strength

|

Hardness

|

Temperature

|

Thickness

|

||||||||

|

Anti-slip rubber sheet

|

OEM

|

500-1500

|

/

|

1.45g/cm

3

-1.8

g/cm

3

|

2.5mpa-3mpa

|

75°±5°

shoreA

|

-35℃-60℃

|

/

|

||||||||

|

Abrasion resistant

|

OEM

|

500-1500

|

/

|

1.4g/cm

3

-1.7g/cm

3

|

≥500psi

and 20mpa

|

75°±5° shoreA

|

-35℃-60℃

|

1mm-100mm

|

||||||||

|

Acid resistant

|

OEM

|

500-1500

|

/

|

1.4g/cm

3

-1.7g/cm

3

|

≥500psi and 15mpa

|

55°-75°shoreA

|

-45℃-100℃

|

1mm-100mm

|

||||||||

|

Insulation

|

OEM

|

500-1500

|

/

|

1.5g/cm

3

-1.9g/cm

3

|

2.5mpa-6mpa

|

65°-75°shoreA

|

-30℃-80℃

|

1mm-100mm

|

||||||||

|

Flame retardant

|

OEM

|

500-1500

|

/

|

1.7g/cm

3

-1.9g/cm

3

|

3mpa-5mpa

|

75°±5° shoreA

|

/

|

1mm-10mm

|

||||||||

|

EPDM

|

OEM

|

500-1500

|

/

|

1.4g/cm

3

-1.7g/cm

3

|

≥500psi and 15mpa

|

75°±5° shoreA

|

-50℃-150℃

|

1mm-100mm

|

||||||||

|

Silicone rubber

|

OEM

|

500-2000

|

Transparent/

color

|

1.25g/cm

3

|

5.5mpa

|

45°-55° shoreA

|

-30℃-200℃

|

0.1mm-50mm

|

||||||||

|

Oil resistant

|

OEM

|

1-50

|

/

|

1.6g/cm

3

-2.0g/cm

3

|

3mpa-8mpa

|

75°±5° shoreA

|

-30℃-60℃

|

1mm-100mm

|

||||||||

|

Environmentally friendly

|

OEM

|

500-1500

|

/

|

1.5g/cm

3

-1.9g/cm

3

|

2.5mpa-6mpa

|

75°±5° shoreA

|

-30℃-80℃

|

1mm-100mm

|

||||||||

|

The form of the kinds of the export rubber boards

|

|

|

|

|

|

|

||||||

|

Type

|

Specification range

|

|

Basic Performance

|

Basic Performance

|

|

|

||||||

|

|

Thickness(mm)

|

Width(mm)

|

Hardness

|

Tensile strength(MPa)

|

Elongation(%)

|

Specific Gravity(g/cm

3

)

|

||||||

|

General rubber sheet

|

1-50

|

914-1600

|

65±5

|

≥4.0

|

≥200

|

1.45±0.05

|

||||||

|

General rubber sheet

|

1-50

|

914-1600

|

50±5

|

≥3.0

|

≥250

|

1.45±0.05

|

||||||

|

General rubber sheet

|

1-50

|

914-1600

|

80±5

|

≥3.0

|

≥150

|

1.50±0.05

|

||||||

|

General rubber sheet

|

1-50

|

914-1600

|

65±5

|

≥5.0

|

≥250

|

1.45±0.05

|

||||||

|

General rubber sheet

|

1-50

|

914-1600

|

65±5

|

≥7.0

|

≥250

|

1.45±0.05

|

||||||

|

CR rubber sheet

|

1-50

|

914-1600

|

65±5

|

≥7.0

|

≥250

|

1.70±0.05

|

||||||

|

CR rubber sheet

|

1-50

|

914-1600

|

65±5

|

≥4.0

|

≥300

|

1.55±0.05

|

||||||

|

EPDM rubber sheet

|

1-50

|

914-1600

|

65±5

|

≥5.0

|

≥250

|

1.45±0.05

|

||||||

|

NBR rubber sheet

|

1-50

|

914-1600

|

65±5

|

≥5.0

|

≥250

|

1.45±0.05

|

||||||

|

Cloth laminated rubber sheet

|

3-20

|

914-1600

|

65±5

|

≥3.0

|

≥200

|

1.50±0.05

|

||||||

|

Cloth laminated rubber sheet

|

3-20

|

914-1600

|

65±5

|

≥5.0

|

≥250

|

1.45±0.05

|

||||||

|

Abrasion resistant rubber sheet

|

1-50

|

914-1600

|

60±5

|

≥18.0

|

≥400

|

1.15±0.05

|

||||||

|

The thickness and width tolerance of rubber board

|

|

|

|

|

|

|

|

|||||||

|

Thickness(mm)

|

tolerance(mm)

|

width(mm)

|

tolerance(mm)

|

Thickness(mm)

|

tolerance(mm)

|

width(mm)

|

tolerance(mm)

|

|||||||

|

1.5

|

±0.20

|

914-1600

|

+20,-0

|

14

|

±0.90

|

914-1600

|

±0.20

|

|||||||

|

2.0

|

±0.30

|

914-1600

|

+20,-0

|

16

|

±1.00

|

914-1600

|

±0.30

|

|||||||

|

3.0

|

±0.35

|

914-1600

|

+20,-0

|

18

|

±1.20

|

914-1600

|

±0.35

|

|||||||

|

4.0

|

±0.40

|

914-1600

|

+20,-0

|

20

|

±1.35

|

914-1600

|

±0.40

|

|||||||

|

5.0

|

±0.45

|

914-1600

|

+20,-0

|

22

|

±1.50

|

914-1600

|

±0.45

|

|||||||

|

6.0

|

±0.50

|

914-1600

|

+20,-0

|

25

|

±2.00

|

914-1600

|

±0.50

|

|||||||

|

8.0

|

±0.55

|

914-1600

|

+20,-0

|

30

|

±2.00

|

914-1600

|

±0.55

|

|||||||

|

10

|

±0.60

|

914-1600

|

+20,-0

|

40

|

±2.00

|

914-1600

|

±0.60

|

|||||||

|

12

|

±0.80

|

914-1600

|

+20,-0

|

50

|

±2.00

|

914-1600

|

±0.80

|

|||||||

Product packaging

Hot Searches