- Product Details

- {{item.text}}

Quick Details

-

Air Pressure(MPa):

-

26 MPa

-

Heating Power (kW):

-

108 kW

-

Air Comsumption(L/min):

-

2 L/min

-

Water Comsumption(L/min):

-

2.5 L/min

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Shuangji

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

12m*2m*2.6m

-

Weight (T):

-

15 T

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Product name:

-

PS food box container making machine

-

Model:

-

SJ-1040

-

Max.forming area:

-

1000*1100

-

Max.forming depth:

-

80mm

-

forming prssure:

-

15T

-

Production efficiency:

-

3-5S/mould

-

Heating power:

-

56kw

-

Total power:

-

120kw

-

Total weight:

-

15T

Quick Details

-

Max.Forming Height(mm):

-

80 mm

-

Forming Width (mm):

-

1000 mm

-

Forming Length (mm):

-

1100 mm

-

Air Pressure(MPa):

-

26 MPa

-

Heating Power (kW):

-

108 kW

-

Air Comsumption(L/min):

-

2 L/min

-

Water Comsumption(L/min):

-

2.5 L/min

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Shuangji

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

12m*2m*2.6m

-

Weight (T):

-

15 T

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Product name:

-

PS food box container making machine

-

Model:

-

SJ-1040

-

Max.forming area:

-

1000*1100

-

Max.forming depth:

-

80mm

-

forming prssure:

-

15T

-

Production efficiency:

-

3-5S/mould

-

Heating power:

-

56kw

-

Total power:

-

120kw

-

Total weight:

-

15T

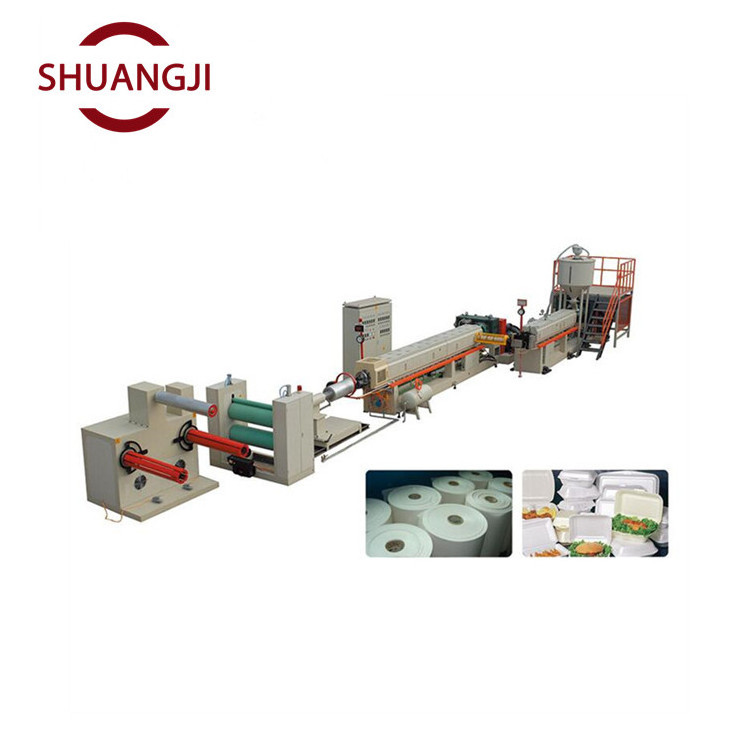

♥ Our company is professioned in manufacturing PS foam sheet extrusion line,fully automatic vacuum forming machine,PE foam sheet production line,PE foam net extrusion line,egg tray production line,etc.We have rich experience in this field.

♥ Our productions are sold not only in domestic,but also abroad market.We have been recgonized by custormers with high quality productions

PS Food Lunch Box Container Making Vacuum Forming Thermoforming Plastic Machine

♥

PSP foam sheet machine

♥

Fully auto forming and cutting machine

♥

Recycle machine

| --------------------PSP foam sheet machine---------------- |

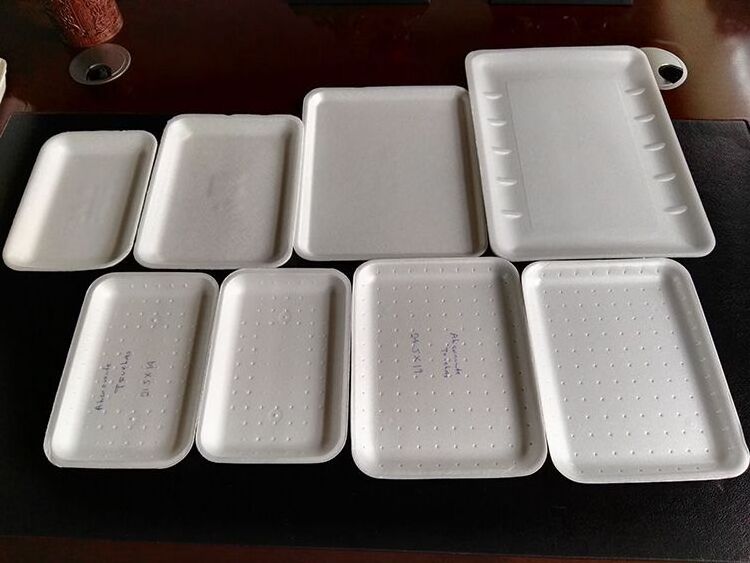

♥ PS Foam Sheet Extrusion Line can used to form many different products such as fast food box, foam tray, foam cup, foam profile and so on.

♥ PS foam sheet is a new-type material with the features of shockproof, sound insulation, haat preservation, dampproof, safety, sanitation and good plasticity. It is used widely in the packing of food, fruit, electronic product, commodity, daily necessities, hardware product, advertisement board, etc.

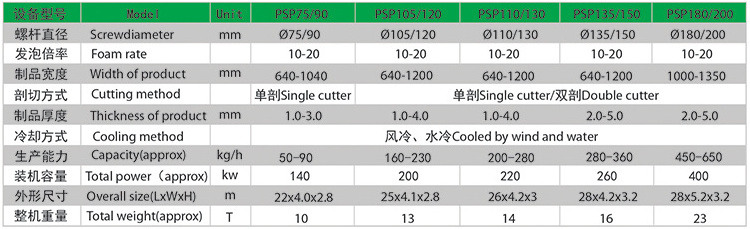

♥ Main technical parameters

| ------------------- Fully auto forming and cutting machine -------------------- |

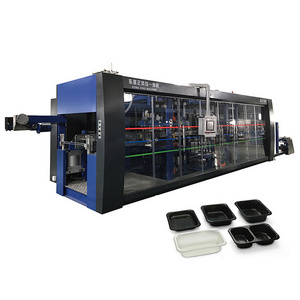

♥ Fully automatic forming and cutting machine integrates forming, cutting and stacking (trimming) at the same time. It has the features of saving labor, improving efficient, lowing labor intensity and reducing production cost. It adopts PLC controller and touch screen to control the working program. Two workers are enough for whole production line.

♥ The machine is plastic sheet forming equipment in one step with following process: transporting sheet, heating, forming, cutting, stacking and winding waste edge.

♥ Main technical parameters

| ----------------------Recycle machine------------------------ |

♥ Plastic recycle and pelletizing machine is designed to reclaim the foamed polystyrene materials almost identically to new ones with its own superior filtering performance.

♥ Structure

-- Extrusion unit

-- T-die with screen changer

-- Cooling water bath unit

-- Pelletizing unit

-- Control panel unit

♥ Main technical parameters

| ----------------------Product advantage---------------------- |

♥

Our PS Foamed Machinery adopts high quality stainless steel refining made. The advantages are non rusty, wear-resisting, elegant surface, fast and convenient feeding material, humanized operation, save labor cost and improve product capacity.

♥

Our PS Foamed Machinery adopts international famous brand hydraulic part,through hundreds of strick testing. More than 80 countries years of using experience prove: this system using effect is reliable and safety, performance reaches to the world's advanced level. The advantages are light weight,small volume, small motion inertia, quick response,big power,low noise, wear well and high degree of automation.

♥

Our PS Foamed Machinery adopts advanced vacuum forming technology, forming and shaping one-time finish. Not only guarantee the product quality, but also improve the product capacity.The working table adopts high strength steel plate,through laser welding, it is big strength and high tenacity. The mold adopts aviation aluminium alloy through tens of process refining made. The advantages are high precision,high strength, light weight, long using life, corrosion assistance, fatigue resistance etc.

♥

Our PS Foam Machinery adopts advanced computer control, combining photo electricity and machinery together. Achieve full automatic of stacking and driving. It saves labor and resource, improve the economic efficiency. The advantages are stacking neatly, accurate counting, reasonable design,advanced technology etc.

♥

We will arrange our professional engineer go to your country to install and test the machine and train your engineers.

♥

Our salesman will be 7*24 hours online for you to solve any problems from your side.

♥

We have been in this line for business for more than 20 years. So we have abundant experience of producing machine.

♥

Our machine is high quality. We are your reliable manufacturer of machine.

♥

Contact with us. We can provide you non-stop service with the pre-sale, sale and after sale service. Save your purchasing cost and maintenance costs