- Product Details

- {{item.text}}

Quick Details

-

type:

-

tire machine

Quick Details

-

Place of Origin:

-

Shandong, China

-

high efficiency:

-

low noise

-

save energy:

-

good after service

-

type:

-

tire machine

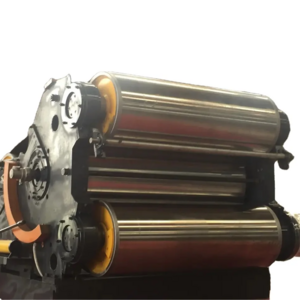

waterproof roll rotocure rubber machine /rotocure rubber vulcanizer machine

It mainly works for calendering of belt after rubber belt building,as can improve the shape and intrinsic quality of rubber belt,

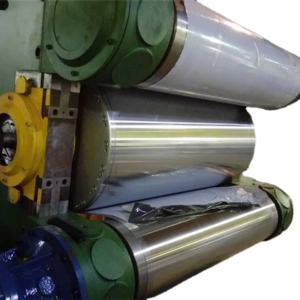

rubber conveyor belt vulcanizing machine / rubber rotoucre machine line include: let off&wind up device,main machine,cleaning device for curing drum&steel belt,bearing,AC VFD,PLC.

1.The drum rolls are the main parts of machine group, which work for curing of rubber belts; the drive rolls connect with the reducer to transfer the drive so that the machine can run in different speed. The steel belt connect all rolls into one drive chain for cooperative motion; the hydraulic device can provice the tension and pressure; EPC centering device can control the running track of steel belt; the hot oil heating device can control the technology temperature; the let-off device transfers the rubber belt to be cured ;the traction device control the tension before and after curing; the wind-up device works for winding of belt.

2. rubber vulcanizing press has compact structure, stable control and convenient maintenance, as can completely meet the requirements of rubber belt manufacturers.

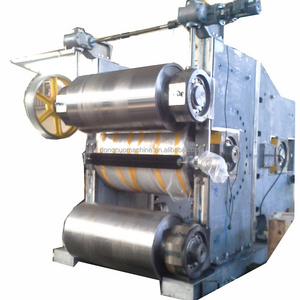

3. rubber vulcanizing press has different structure from platen press, which has specially designed structure to reach continuous production with perfect performance. The curing temperature and pressure are stable. It can produce hundreds of meters and even thousands of meters circle belt.

4. PLC control for the machine works fully to meet the technology and operation requirements. The line speed, working pressure and tension can be adjusted to meet different rubber belt curing requirements.

Rotary curing machine

|

model Item |

DLG700×1400-1800 |

DLG1100×2000 |

DLG1500×2000-2500 |

DLG2000×2500-4200 |

||

|

Max. product width |

mm |

1200-1600 |

2000 |

2000-2500 |

2500-4200 |

|

|

Max. product thickness |

mm |

5 |

8 |

12 |

12 |

|

|

Drum dia. |

mm |

700 |

1100 |

1500 |

2000 |

|

|

Drum working width |

mm |

1400-1800 |

2200 |

2350-2750 |

2750-4200 |

|

|

Total pulling force of steel belt |

T |

38-49 |

90 |

93.6-117 |

120-144 |

|

|

The linear speed of vulcanizing drum |

m/min |

1.12-0.04 |

0.06-1.8 |

0.175-3.14 |

0.24-4.7 |

|

|

Steam pressure |

MPa |

0.6 |

≤0.8 |

≤1 |

≤1 |

|

|

Vulcanizing temperature |

°C |

1140-160 |

140-160 |

160-180 |

160-180 |

|

|

Main motor power |

kW |

4,5.5 |

7.5 |

7.5-11 |

15~30 |

|

|

Overall dimensions |

L |

mm |

8300 |

10000 |

1350 |

18600 |

|

W |

mm |

4400-4830 |

4900 |

5200 |

4650-6200 |

|

|

H |

mm |

2100 |

2600 |

6085 |

6285 |

|

|

About weight |

t |

~20-30 |

~42 |

~79 |

~80-126 |

|

The use of Rotary Curing Machine

It is mainly in use of vulcanizing various kinds of rubber plates,

conveyor belt, waterproof material, printing mackintosh,

rubber & plastic floor mat and other board-shaping products.

Also according to customers’ technical requirement, we do

custom-tailor the vulcanizing machine lines.