- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

FL-MD-0034, FL-MD-0034

-

Mould material:

-

Steel Mold

-

Surface treatment:

-

Polishing

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Fenglin

-

Model Number:

-

FL-MD-0034, FL-MD-0034

-

Mould material:

-

Steel Mold

-

Surface treatment:

-

Polishing

PRODUCT DESCRIPTION

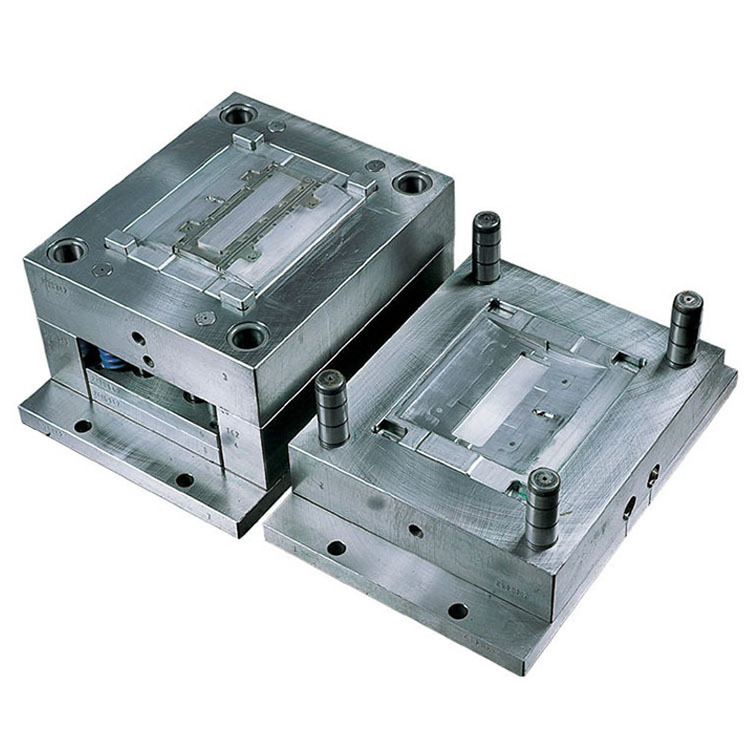

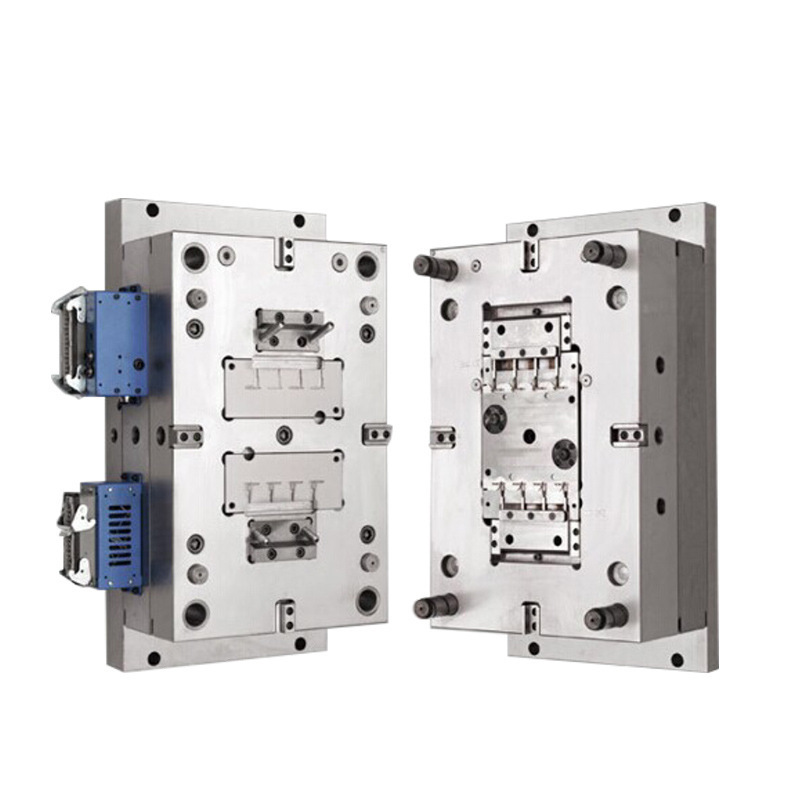

Plastic Product (Front)

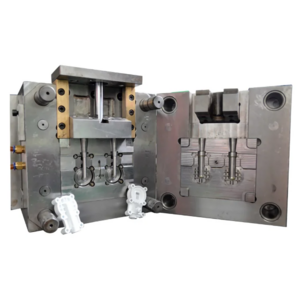

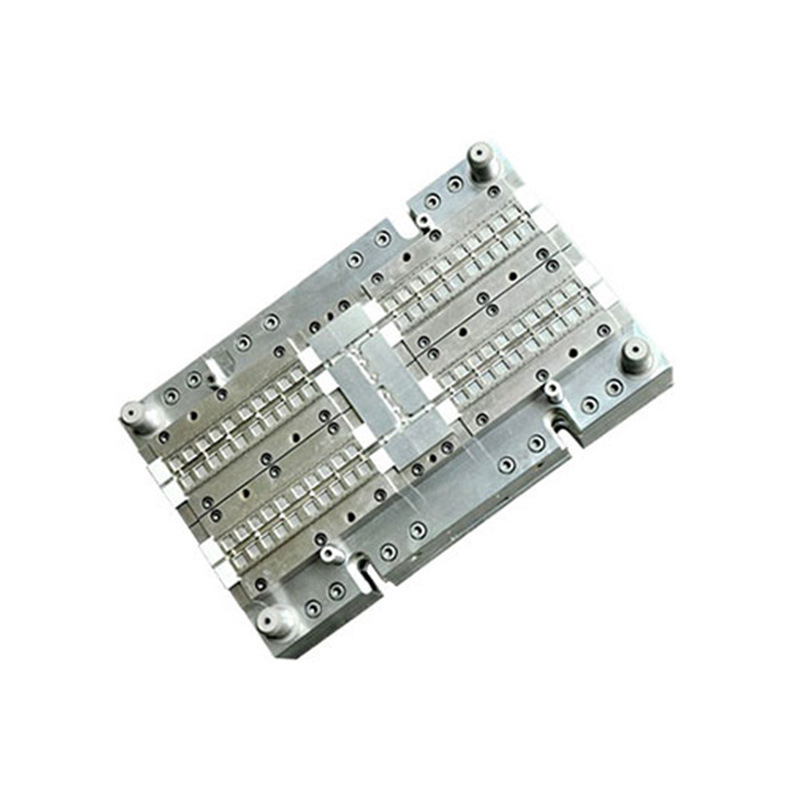

All kinds of injection mold

precision mould

design and making

Suitable for ABS PVC PP PC etc. materials

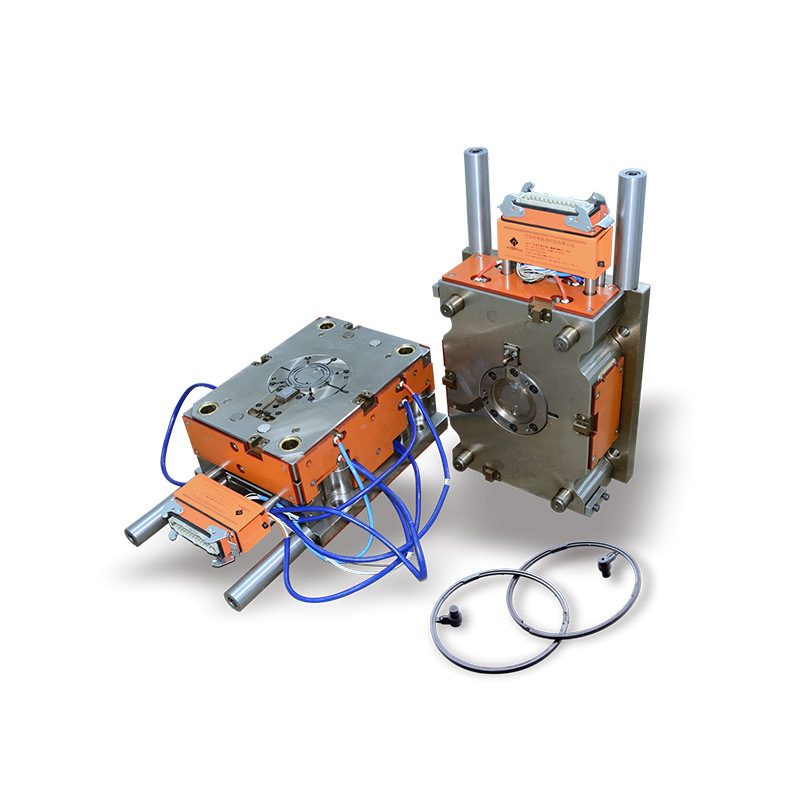

Plastic Product (Back)

All kinds of injection plastic molding for industrial /

communication / Electronics / Medical /

Food, plastic electronic parts or finished products

PRODUCT PARAMETERS

|

Description

|

Contents

|

|

|

|

|||

|

Products Name

|

Injection Mold and Plastic Molding

|

|

|

|

|||

|

Mold Base

|

LKM / HASCO etc.

|

|

|

|

|||

|

Mold Materials

|

S136/P20/718/738/2344/NAK80 /8407/SKD61/H13 etc.

|

|

|

|

|||

|

Mold Precision

|

+/-0.01 mm

|

|

|

|

|||

|

Mold Life Times

|

300000-500000 shots( depending on customer's inquiry)

|

|

|

|

|||

|

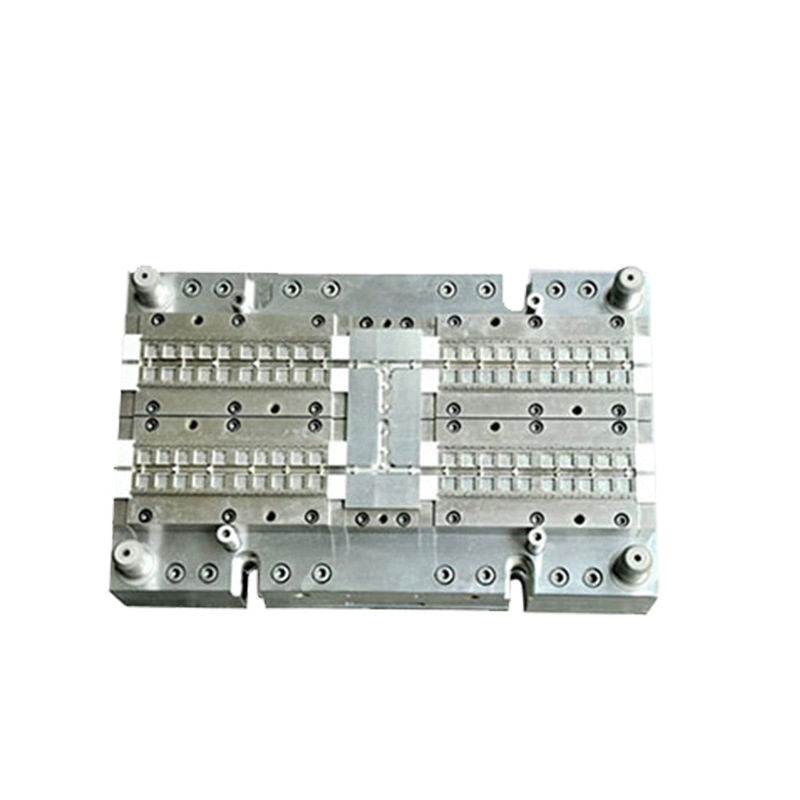

Mold Cavity

|

Single or Multi-Cavity

|

|

|

|

|||

|

Runner System

|

Hot or Cold Runner

|

|

|

|

|||

|

Gate Type

|

Pinpoint Gate , Edge Gate, Sub Gate, Film Gate, Valve Gate, Open Gate, etc.

|

|

|

|

|||

|

Equipment

|

High speed precision CNC , EDM , Milling , Wire cutting, Grinder, plastic injection molding from 120 T-1000 T and Two sets double colored injection molding machines

|

|

|

|

|||

|

Plastic Materials

|

PA6, PA66, ASA, ABS, PP, PC, PE, PMMA, TPE, TPU, PEI, PBT, PTFI, POM, PPS, ABS+GF, ABS+PC , HDPE, PEEK, NYLON, SILICONE, RUBBER etc.

|

|

|

|

|||

|

Surface Treatment

|

Polishing / Smooth, Texture /Frosted, Painting , Plating, Printing,etc.

|

|

|

|

|||

|

Custom Feature

|

3D/2D drawings ( PDF, STP, STEP, JPG, STL, etc. ) or Samples provided

|

|

|

|

|||

|

Quality System

|

SGS / ISO 9001:2015 / CNAS

|

|

|

|

|||

COMPANY PROFILE

COMPANY PROFILE

Dongguan Fenglin Industry Co., Ltd. was founded in 2013 which is located in Dongguan City, covered 5000square meters with more than 200 employees.

After more than twenty years of development, We has become a modern high-tech、diversified and international enterprise integrating R&D, sales, producing and service.

We provide researching & developing 、designing 、producing 、sales and technical support services to our customers. Honest, Diligent, Graveness is our enterprise spirit.

Customer’s satisfaction is our most priority in our business co-operation , We meet varieties requirement of our customers with reasonable price、high quality products and excellent service and make them satisfied.

Any inquiries and business negotiations are warmly welcomed and we hope have the chance to establish a harmonious business relationship and long term co-operation in the near future.

DONGGUAN FENGLIN INDUSTRY CO.,LTD.

FENGLIN INDUSTRY CO.,LTD.

HUNAN FENGANG TECHNOLOGY CO.,LTD

COMPANY HISTORY

In 2002 Established Dongguan Taixing Plastic Mould Factory

In 2009 Established Dongguan Fengang Tech. Co. , Ltd.

In 2013 Established Dongguan Fenglin Industry Co.,Ltd.

In 2020 Established Dongguan Hongsheng Plastic Mold Co.,Ltd.

In 2020 Established Dongguan Hongsheng Plastic Mold Co.,Ltd.

In 2021 Established Hunan Fengang Technology Co.,Ltd.

WHY CHOOSE US

QUALITY GUARRANTEE

We have a professional teams to control the quality. Experienced engineers, precision machines,

CMM and closed-loop QC system.

CUSTOMER SERVICES

Our clients are served by a specialized sales for timely technical support and after-sales service.

ONE-STOP SOLUTION

From mold design, mold making, machining, producing, welding, surface treatment, injection molding ,checking , assembling, QC, packing and shipping.

OUR OFFICE

We have professional management /

production/ quality control/ purchasing/

R&D / Logistic / Finance/ sales Dept.

OUR R&D DEPT.

We have a group of more than ten years of experience of professional technical team, focus on mold and injection products research

and development design.

and development design.

OUR EQUIPMENTS

1. 36 sets high-speed precision injection

molding machines

2. 2 sets 400 T two-color molding machines.

3. M

edical and food grade dust-free injection

molding workshop

4. from 120 Ton - 1000 Ton

OUR WORKINGSHOP

We have a group of more than ten years of production and manufacturing veteran staff, as well as after-sales, logistics support service teams.

OUR MOLD DESIGN PROCESS

Step 2: Negociate the price of the mold process and injection plastic moulding

Step 4: Create the Design for Manufacturing (DFM) report

Step 5: Made the mold flow analysis

Step 6: Design tooling drawings

Step 7: Mold making

Step 8: Making Samples and confirmation the quality between customer and our QC dept.

INJECTION MOLD MAKING PROCESS

Raw Material

Laser positioning

Drilling Hole

Grinding Processing

WEDM

Finishing

Polishing

Assembling

Mould Testing

CERTIFICATIONS

FAQ

1. How long does it make an injection mold?

Normally it will take our 35-45 days ,

depending on the complexity and cavity Number of the mold design.

2.

How soon can I get the quotation?

In order to quote for you earlier, please provide us the following information together with your inquiry

1) 3D or 2D Drawings ,videos ,samples

2) Material requirement (mold and plastic parts)

3) Surface treatment

4) Quality requirement

and other information (such as size/weight/tolerance etc.)

5) Quantity (per order/per month /annual )

6) Any special demands or requirements, such as silk screen , packing, labels, payment and delivery terms etc.

3. How to ensure the mold making methods are correct ?

To avoid the misunderstanding ,We will offer DFM report ( Design for Mold included the parting line, ejector pin

location,

plastic thickness, draft etc information) and mold structure for you to check the project detail before

the mold making.

4. How to follow up our order schedule?

Send us inquiry--received our quotation--negotiate order details--sign the contract--pay deposit--confirm the mold

design-- make mold --mold testing--confirm plastic injection molding samples--balance payment of molds

-deposit for plastic molding parts mass production--products inspection and packing -cargo ready-balance payment

-delivery the cargoes--customers

feedback and solutions—further cooperation.

5.

How about your mold life times?

300000-500000 times

6. What kinds of certificate do you have

?

SGS reports / GB/T19001-2016/ISO 9001:2015

7.Can you provide product assembly service

Yes,

we can provide production run and assembly service.

8.How many equipment in your factory?

24 sets high speed precision injection molding machine from 120 T-1000 T

12 sets 250 T injection molding machines in a m

edical grade and food grade dust-free injection molding workshop

2 sets 400 T two-color injection machines ,

CNC , drilling , milling etc. other equipment

9.

What is your payment term?

T/T or L/C is workable to you, normally we accept T/T 50% with order, and the balance needed to be paid before

shipping.

10. How about your delivery terms?

EXW / FOB ports of Shenzhen / Guangzhou ( or other recommended ports of China)

2) Material requirement (mold and plastic parts)

3) Surface treatment

5) Quantity (per order/per month /annual )

6) Any special demands or requirements, such as silk screen , packing, labels, payment and delivery terms etc.

300000-500000 times

7.Can you provide product assembly service

T/T or L/C is workable to you, normally we accept T/T 50% with order, and the balance needed to be paid before

RECOMMEND PRODUCTS

Hot Searches