__

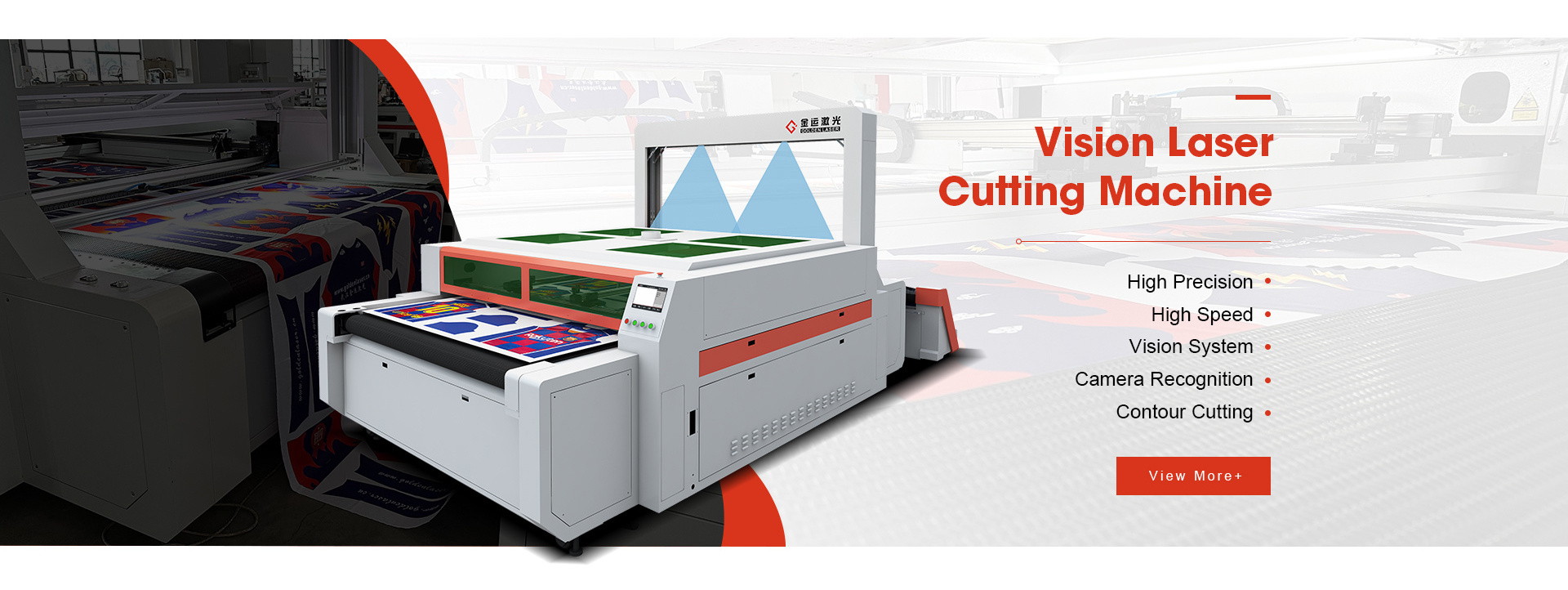

Loading the dye-sublimated roll fabrics to the conveyor working table of laser cutter with auto-feeder.

|

CJGV-160130LD

Technical Parameters

|

|

|

|

Working area

|

1600mm×1300mm (63″×51″)

|

|

|

Camera scanning area

|

1600mm×800mm (63″×31.4″)

|

|

|

Working table

|

Conveyor working table

|

|

|

Laser type

|

CO2 glass laser / CO2 RF metal laser

|

|

|

Laser power

|

150W x 2 / 300W x 2

|

|

|

Cutting speed

|

0-800 mm/s

|

|

|

Positioning accuracy

|

±0.1mm

|

|

|

Motion system

|

Servo motor

|

|

|

Cooling system

|

Constant temperature water chiller

|

|

|

Exhaust system

|

1.1KW exhaust fan × 2, 550W exhaust fan × 1

|

|

|

Power supply

|

AC220V±5% 50Hz / 60Hz, Single phase

|

|

|

Power consumption

|

9KW

|

|

|

Software

|

GoldenCAD Scanning Software Package

|

|

|

Space occupation

|

4316mm (L)×3239mm (W)×2046mm (H) (170”×127”×80” )

|

|

|

Options

|

Auto feeder, red dot pointer

|

|