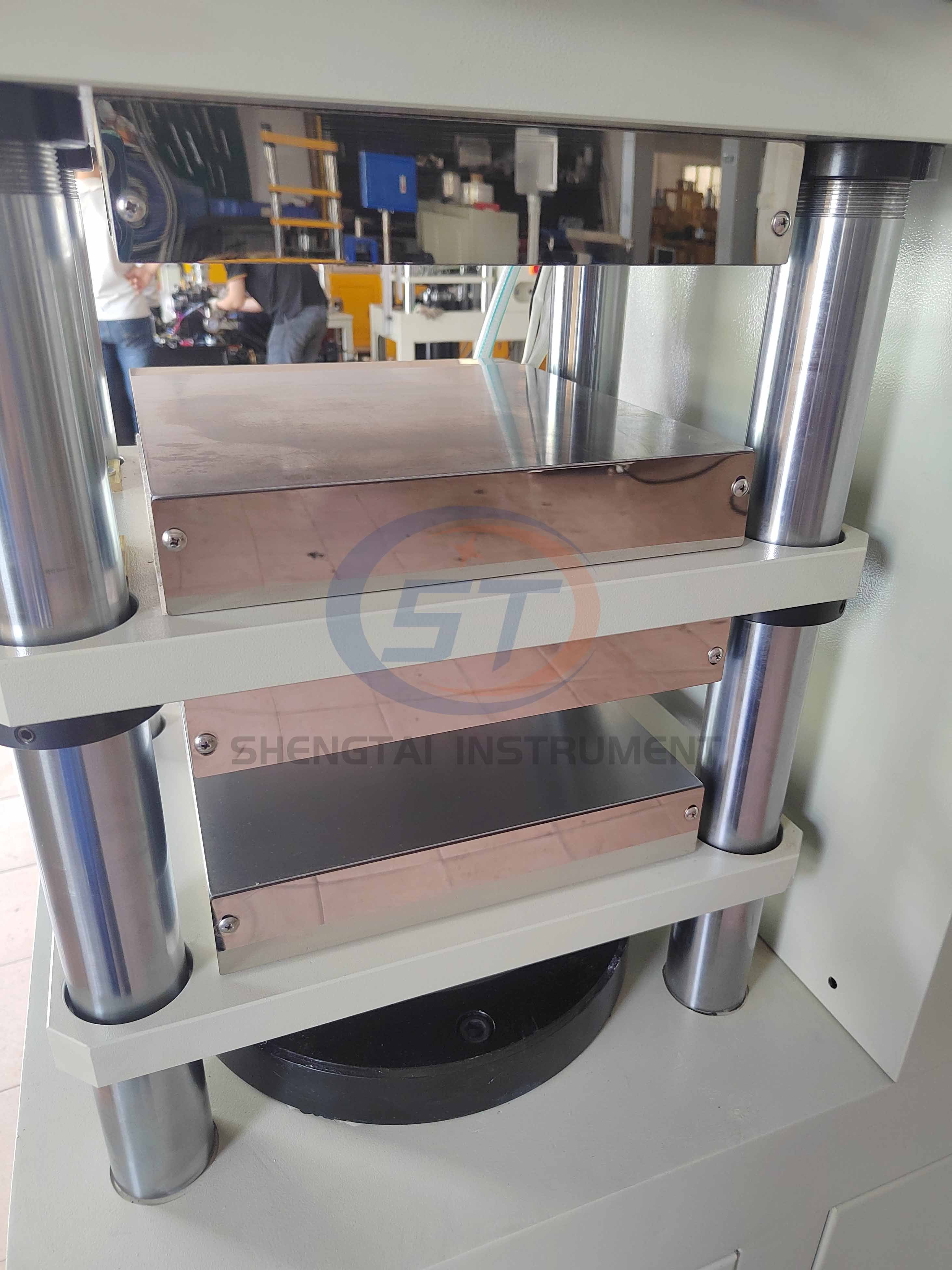

Heating plate: imported high-temperature steel, surface by deep carbonation, hard chromium plating process, with fast heat

transfer, corrosion resistance, high hardness, no deformation and so on. Built-in heater and temperature sensor on the back, large

power, rapid temperature rise, sensitive temperature measurement, uniform temperature error range.

Guide column: four hardened and precisely positioned columns and hydraulic cylinders, supporting the hydraulic platform by the

thick steel plate seat of the entire control box, on the column with self-lubricating bronze bearings, guide sliding, smooth

lifting, no noise; tablet machine The top and rear, surrounded by heavy steel, provide additional security for the operator; the

upper layer is a steel plate - with an inserted thermocouple near the middle surface.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1000*500*1500mm

-

Weight:

-

658

-

Power (kW):

-

3KW

Quick Details

-

Place of Origin:

-

GUA

-

Brand Name:

-

ST

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1000*500*1500mm

-

Weight:

-

658

-

Power (kW):

-

3KW

Product Description

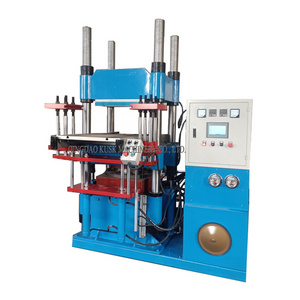

High Quality rubber vulcanizer press / Hydraulic rubber vulcanizing press/ rubber press machine

Introduction:

The plastics and rubber raw materials are placed in a mold and added pressure and temperature on material to form the raw materials for testing and serve as a basis for mass production of ingredients in the factory.

1: Capacity:30tons (10,20,30,50,100,200 etc.) pressure 5~18 MPA adjustable

2: Temperature range: RT~300 degrees

3:Controller: LED digital display, enter by keys.

4: Heating mode: electronic heater tube

5: Plate size: 300*300*40mm

6: Space: 80mm

7:Plate material: SKD Chrome molybdenum alloy

8:Plate surface: HRC60 Mirror chrome

9: Working layers: 2 layer. Top layer: heating; bottom layer: cooling

10: Oil pressure system: GPY oil pump drives high-performance electro-hydraulic injection to non-resistance oil cylinders to

perform equal-rate control mode, with automatic pressure compensation and oil pump delay shutdown function.

11: Hydraulic medium:40L Mobil 46# Antifreeze Hydraulic Fluid (Customer-supplied)

21:Power: 8KW

22:Volume: 920*470*1425mm

23:Weight: 658kg

Specification

|

capacity

|

10,20,30,50,100,200, etc.

|

|

Temperature

|

RT- 300 degrees

|

|

Controller

|

digital control or touch screen control optional

|

|

Heating plate material

|

SKD Chrome molybdenum alloy/HRC60 Mirror chrome

|

|

Platen size

|

300*300*40(it can be customization)

|

|

Working layers

|

There are two kinds of choice

1: Only one working layer for heating

2: Double working layers,one for heating and one for cooling

|

Heating plate

Control Panel

These are control systems

Including time and temperature

Heating and pressure adjusting control.

You can control the machine by these keys.

Pressure regulator valve:

The pressure of the equipment can be adjusted, and the locking function is provided to prevent damage caused by over-hydraulic

equipment.

equipment.

Hydraulic system:

1. GPY oil pump drives high-performance electro-hydraulic injection resistance-free oil cylinders to perform equal-rate control

mode with automatic pressure compensation and oil pump time-out stop function2. Cylinder speed: 11~50mm/s double speed

function, fast mold closing and slow mold clamping: high close speed in low pressure and low close speed in high pressure

mode with automatic pressure compensation and oil pump time-out stop function2. Cylinder speed: 11~50mm/s double speed

function, fast mold closing and slow mold clamping: high close speed in low pressure and low close speed in high pressure

Hot Searches