- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Syringe Gasket

-

Product name:

-

Syringe Gasket

-

Material:

-

Silicone Rubber EPDM NBR NR

-

Color:

-

Customer's Request

-

Application:

-

Widely Used

-

Certification:

-

ISO9001

-

MOQ:

-

100pcs

-

Hardness:

-

20~90 ShoreA

-

Sample:

-

Sample Avaliable

-

Packing:

-

Plastic Bag+carton

-

Quality:

-

High-Quality

Quick Details

-

Processing Service:

-

Moulding

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

LongCheng

-

Model Number:

-

Syringe Gasket

-

Product name:

-

Syringe Gasket

-

Material:

-

Silicone Rubber EPDM NBR NR

-

Color:

-

Customer's Request

-

Application:

-

Widely Used

-

Certification:

-

ISO9001

-

MOQ:

-

100pcs

-

Hardness:

-

20~90 ShoreA

-

Sample:

-

Sample Avaliable

-

Packing:

-

Plastic Bag+carton

-

Quality:

-

High-Quality

Products Description

at Rubber Gaskets are available in the following elastomers:

* Aflas® or Kalrez®(FFKM)

* Acrylate Rubber(ACM)

* Butyl Rubber(IIR)

* Ethylene-propylene (EPR, EPDM)

* Ethylene Acrylate Rubber(AEM)

* Fluorocarbon (FKM/FPM)

* Fluorosilicone(FVMQ)

* Hydrogenated Nitrile (HNBR)

* Liquid Silicone Rubber(LSR)

* Neoprene Rubber(CR)

* Nitrile Rubber (Buna-N/NBR)

* Natural Rubber(NR)

* Polyurethane(PU)

* Silicone Rubber

* Styrene-butadiene Rubber (SBR)

If you need a special compound for the Flat Rubber Gaskets, we can develop one for you.

* Aflas® or Kalrez®(FFKM)

* Acrylate Rubber(ACM)

* Butyl Rubber(IIR)

* Ethylene-propylene (EPR, EPDM)

* Ethylene Acrylate Rubber(AEM)

* Fluorocarbon (FKM/FPM)

* Fluorosilicone(FVMQ)

* Hydrogenated Nitrile (HNBR)

* Liquid Silicone Rubber(LSR)

* Neoprene Rubber(CR)

* Nitrile Rubber (Buna-N/NBR)

* Natural Rubber(NR)

* Polyurethane(PU)

* Silicone Rubber

* Styrene-butadiene Rubber (SBR)

If you need a special compound for the Flat Rubber Gaskets, we can develop one for you.

|

Product Info

|

|

|

|

|

|

|

|

Name

|

Syringe Gasket

|

|

|

Material Type

|

NBR,EPDM,SILICONE,FKM,SBR,NR,etc.

|

|

|

Hardness Range

|

20-90 Shore A

|

|

|

Color

|

Any color is OK

|

|

|

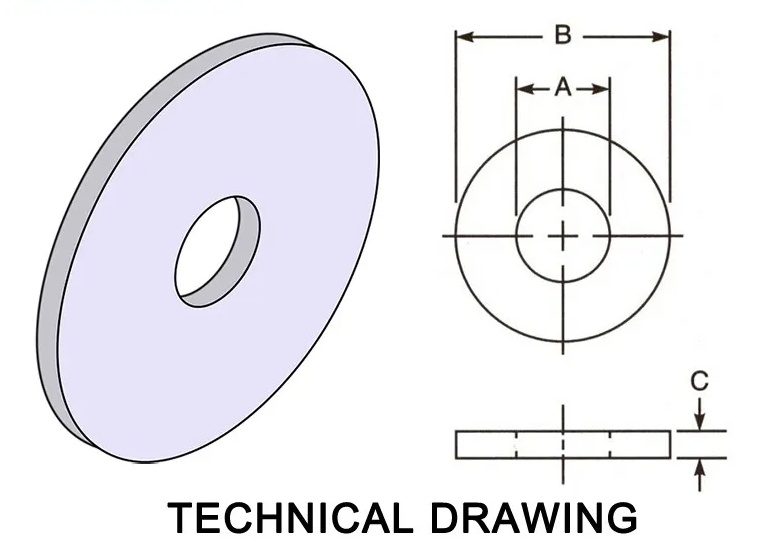

Size

|

As per drawing dimensions

|

|

|

Material Characteristic

|

See below rubber materials properties

|

|

|

Application

|

For all industries

|

|

|

Certificates

|

ISO 9001 、CE

|

|

|

OEM / ODM

|

Available

|

|

|

Packing Details

|

PE plastic bags then to the carton / as per your request

|

|

|

Lead Time

|

7 days for prototype tooling & samples, 14 days for production mold, 14-28 days for MOQ

|

|

|

Shipping Method

|

SEA,AIR,DHL,UPS,FEDEX,TNT, etc.

|

|

|

Payment Terms

|

T/T, L/C, Paypal, Western Union

|

|

|

Quality Acceptance Criteria

|

According to customer's requirements

|

|

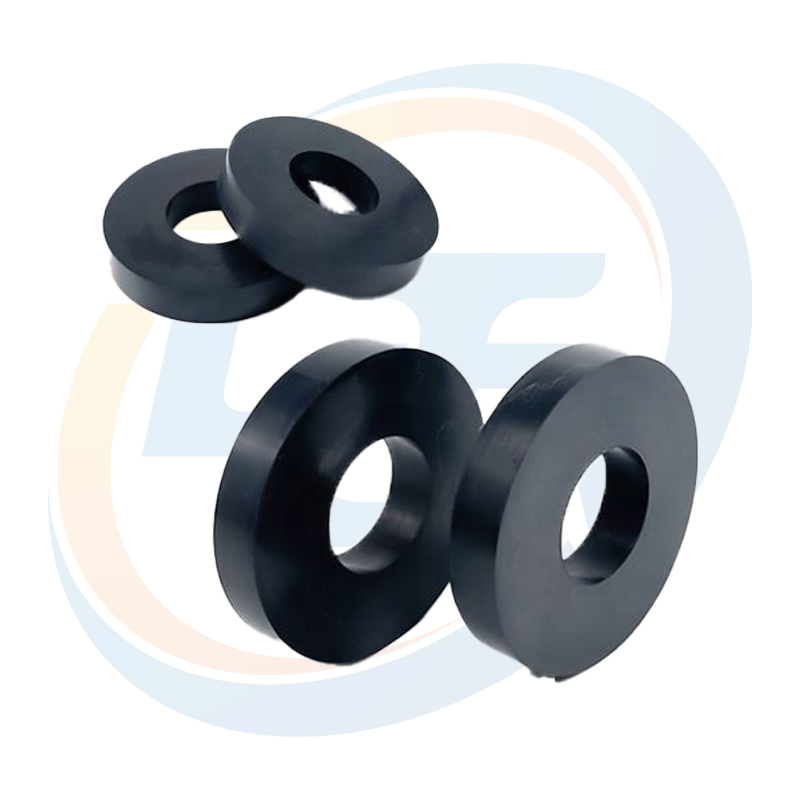

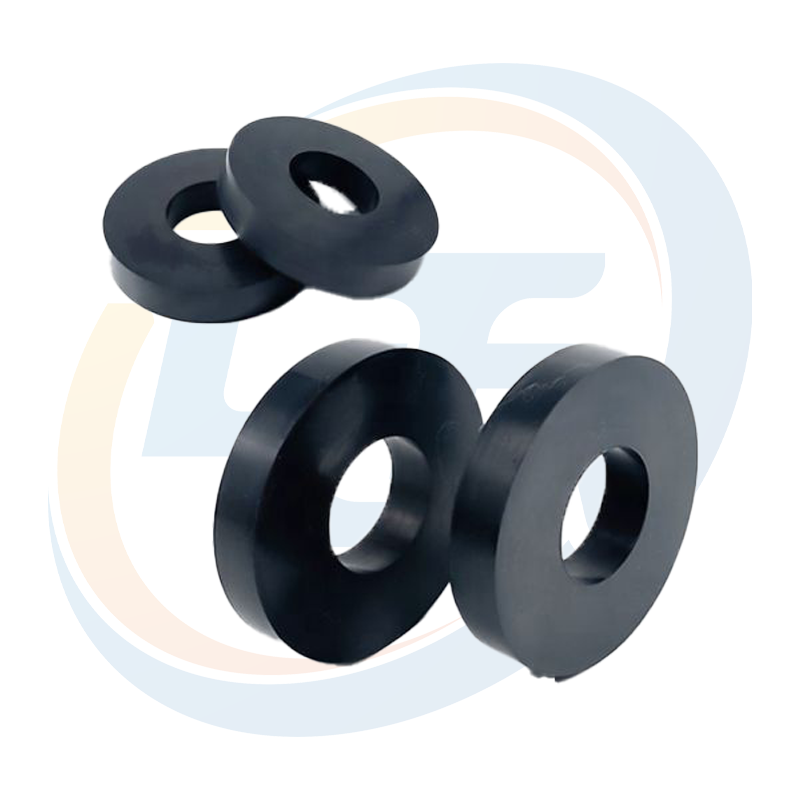

Product Display

Main Product

Company Factory Capacity

Certifications

Production Line

FAQ

Q 1. What's the payment term?

A: We accept T/T 30% deposit and 70% balance against copy of B/L or L/C at sight, West Union,VISA,Paypal is also accepted.

Q 2. What is the normal lead time for product orders?

A: Average lead times for prototype / first article are 1-2 weeks, if tooling is involved, lead time for production tooling is 10

days, average production time after sample approval is 2-3 weeks.

Q 3. What is your standard packing?

A: All the goods will be packed by carton box and loaded with pallets. Special packing method can be accepted when needed.

Q 4. Could you please tell us the month capacity of your products ?

A: It depends on which model, we produce more than 2500 tons rubber materials per month.

Q5: How to check the quality of the bulk order?

A1: We provide preproduction samples before mass production for all customers if needed.

A2: We provide quality certs such as measurement report, material data sheet, COO, COA, etc. to all customers before delivery.

A3: We accept third party inspection such as S G S, TUV, INTERTEK, BV, etc.

Q6: How to select the raw compound for my application?

A: With years of experience working with a variety of material, we can help select the material that will best suit your needs

while keeping material costs in mind.

Q 7: Do you use any international standards for the rubber products?

A: Yes, we mainly use ASTM D2000 standard to define the quality of the rubber materials, tolerances as per ISO3302, ISO2768, etc.

Q 8:Can you supply different color materials?

A: Yes, we can produce custom molded rubber and silicone rubber products in different colors, the color code will be required in

case of an order.

Q9: What materials are available to produce from your side?

A: NBR, EPDM, SILICONE, FKM, NEOPRENE(CR), NR, IIR, SBR, ACM, AEM, Fluorosilicone(FVMQ), FFKM, Liquid Silicone, Sponge, etc.

Q13: How many shifts per day in the factory?

A: Two shifts per day, 8 hours per shift.

A: We accept T/T 30% deposit and 70% balance against copy of B/L or L/C at sight, West Union,VISA,Paypal is also accepted.

Q 2. What is the normal lead time for product orders?

A: Average lead times for prototype / first article are 1-2 weeks, if tooling is involved, lead time for production tooling is 10

days, average production time after sample approval is 2-3 weeks.

Q 3. What is your standard packing?

A: All the goods will be packed by carton box and loaded with pallets. Special packing method can be accepted when needed.

Q 4. Could you please tell us the month capacity of your products ?

A: It depends on which model, we produce more than 2500 tons rubber materials per month.

Q5: How to check the quality of the bulk order?

A1: We provide preproduction samples before mass production for all customers if needed.

A2: We provide quality certs such as measurement report, material data sheet, COO, COA, etc. to all customers before delivery.

A3: We accept third party inspection such as S G S, TUV, INTERTEK, BV, etc.

Q6: How to select the raw compound for my application?

A: With years of experience working with a variety of material, we can help select the material that will best suit your needs

while keeping material costs in mind.

Q 7: Do you use any international standards for the rubber products?

A: Yes, we mainly use ASTM D2000 standard to define the quality of the rubber materials, tolerances as per ISO3302, ISO2768, etc.

Q 8:Can you supply different color materials?

A: Yes, we can produce custom molded rubber and silicone rubber products in different colors, the color code will be required in

case of an order.

Q9: What materials are available to produce from your side?

A: NBR, EPDM, SILICONE, FKM, NEOPRENE(CR), NR, IIR, SBR, ACM, AEM, Fluorosilicone(FVMQ), FFKM, Liquid Silicone, Sponge, etc.

Q13: How many shifts per day in the factory?

A: Two shifts per day, 8 hours per shift.

Hot Searches