Hyraulic pressure molding technology adopted to assure the steady running of brick machine. Bricks produced are of larger density and higher strength.

- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, OTHER, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

linyi fulang

-

Voltage:

-

330v

-

Dimension(L*W*H):

-

1200*1500*2100mm

-

port:

-

qingdap

-

pressure:

-

22 mpa

-

weight:

-

480kg

-

demoulding type:

-

hydrualic

-

machine type:

-

interlocking brick machine

-

raw material:

-

soil,sand

-

package:

-

wooden

-

motor:

-

siemens

-

Certification:

-

ce,iso9001

Quick Details

-

Type:

-

Interlock Block Making Machine

-

Brick Raw Material:

-

Clay

-

Production Capacity (Pieces/8 hours):

-

3200/day

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, OTHER, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

linyi fulang

-

Voltage:

-

330v

-

Dimension(L*W*H):

-

1200*1500*2100mm

-

port:

-

qingdap

-

pressure:

-

22 mpa

-

weight:

-

480kg

-

demoulding type:

-

hydrualic

-

machine type:

-

interlocking brick machine

-

raw material:

-

soil,sand

-

package:

-

wooden

-

motor:

-

siemens

-

Certification:

-

ce,iso9001

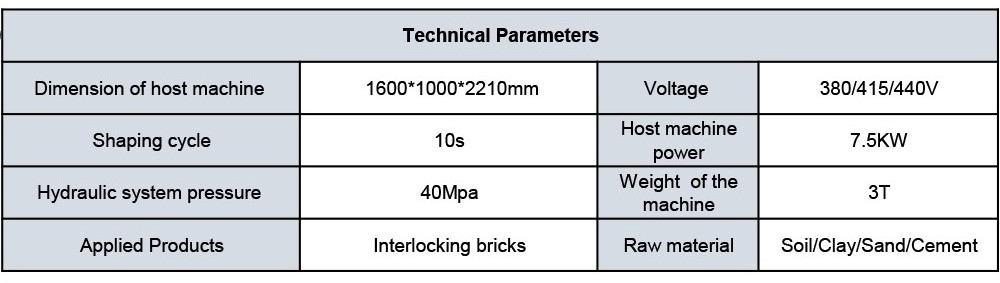

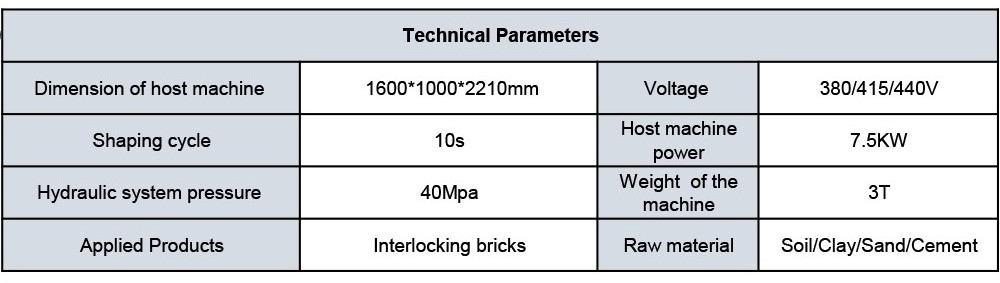

FL2-10 Hydraulic Compressed Earth Clay Interlocking Brick Making Machine

Main Features

1. Function

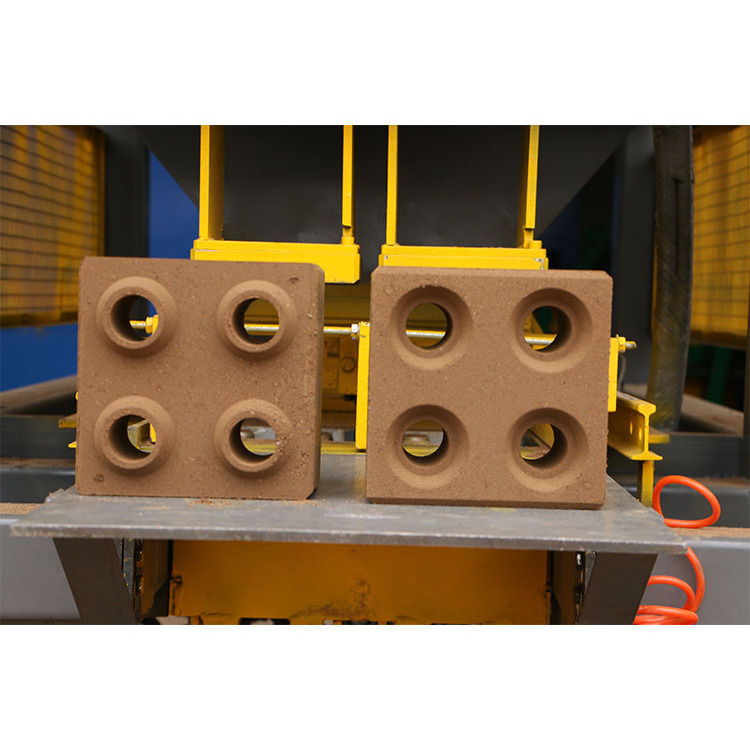

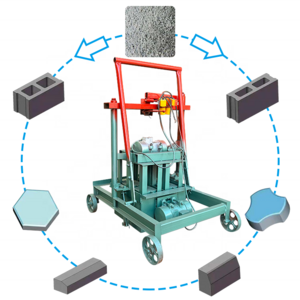

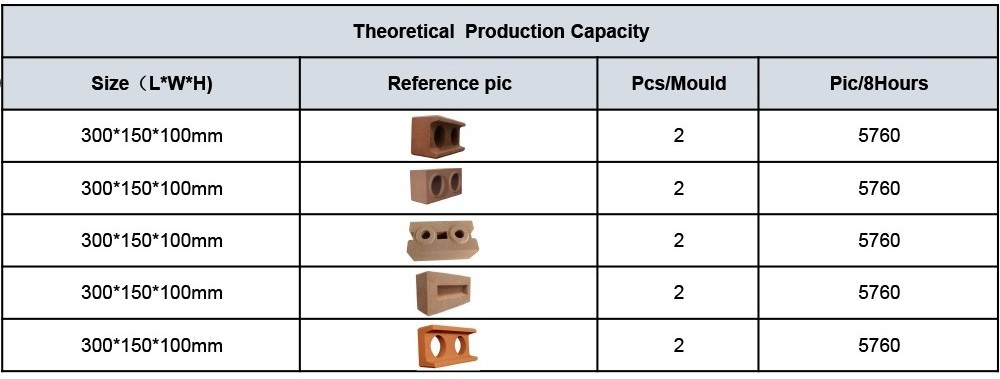

FL2-10 atomatic brick making machine can produce different shapes interlocking bricks by changing mould. Besides, the mould can be designed according to the need of customer.

2. High production efficiency

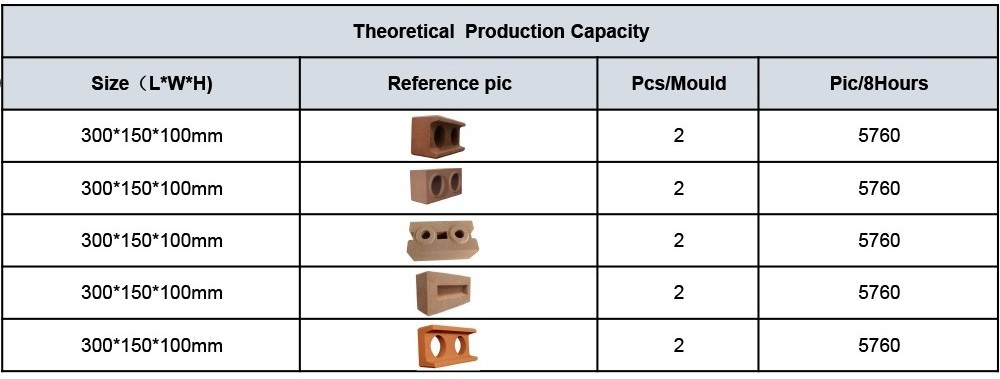

This clay interlocking compressed earth soil block brick making machine is a high efficient machine and the shaping cycle is 10s. The production can start and finish just by pressing start button, so the production efficiency is high with labor saving, it can produce 5760 pieces bricks per 8 hours.

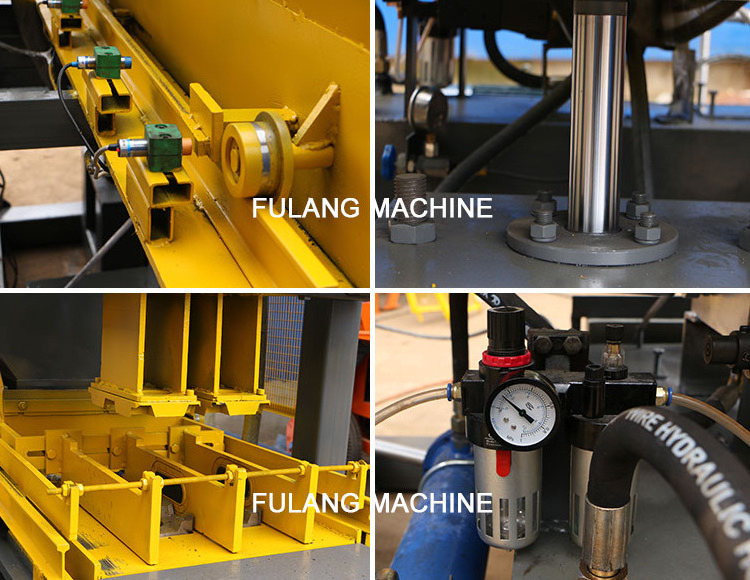

3. Advanced technology

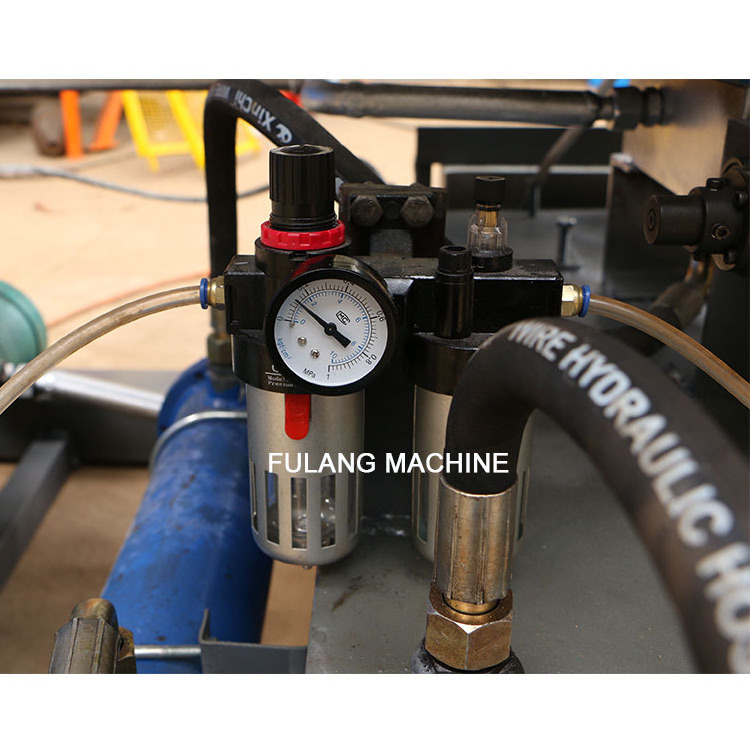

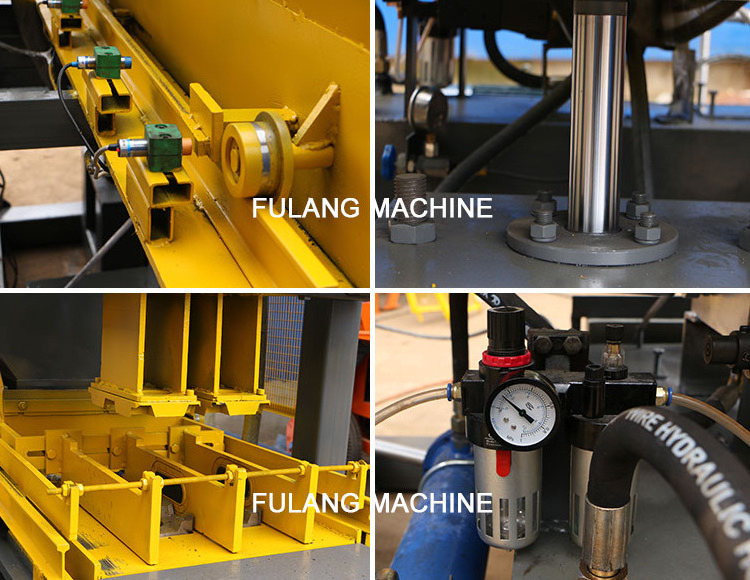

Hydraulic pressure molding technology is adopted by this machine, and the pressure can arrive at 40 MPa, so the blocks produced are of good quality, large density and high strength.

4. High quality mould

The company adopts the most advanced cutting technology and heat treatment technology to ensure product quality and ensure customers' ease.

Advanced technology

Ectromagnetic valves

Solenoid valve will use YUKEN brand which is the

biggest electromagnetic valve manufacturer in Japan to

assure brick making machine run stably.

Brick mould

Soil mixer is installed in the machine which supply the material in time .All the power is provided by the hydrauliac system

PLC Control

1. Select original Mitsubishi PLC control system and famous brand relay to assure stable and high-efficiency working status of the machine.

2. It is a a functioning and flexible application and has high reliability, strong anti-interference ability.

3. Easy to learn and operate.

FL2-10 full automatic clay interlocking brick making machine can produce various different bricks by changing mould. The following bricks are some common brick types. We can also customize the brick mould according to your specific requirements.

Our Company

FULANG Machinery Group Co.,Ltd .is a Chinese manufacturer of dedicated machinery for construction blocks and panels.Our company offers complete production lines for premium building components such as the autoclaved sand -lime brick, autoclaved aerated concrete brick,and autoclaved aerated concern/autoclaved lightweight concrete panel.Additional,we provide various types of pressure vessels and block-making machines.By choosing FULANG,customers can enjoy professional benefits with our dedicated services for design,install,layout planning,technology transfer,and production guidance.

Customers visiting

With 19 years development ,our products have been sold to more than 80 countries.Till now,about 1200 customers have visited our factory.Also we have engineers stay abroad to help you install the machines and training your workers at your side.

The FAQ

1.Q: What kind of payment terms do we accept?

A:T/T and L/C are common for us. Other ways are ok by negotiation.

2.Q:How about your Production time ?

A: Normally 20-25 days after your deposit.

3.Q: Can I visit your factory?

A: Yes. Many domestic and international customers visit our factory every year.

4.Q: Do you provide after-sale service?

A: Yes. We have a professional after-sale service team to promptly and thoroughly solve your problems.

Our Service

Pre-Sales

1.Perfect 7*24 hours inquiry and professional consulting services.

2.Visit our factory anytime.

Sale

1.Update the production schedule in time.

2.Quality supervision.

3.Production acceptance.

4.Shipping on time.

After-Sales

1.Warranty period : 2 YEAR after acceptance, during this period we will offer free spare parts if they are broken.

2.Training how to install and use machine.

3.Engineers available to service overseas.

4.Skill support the whole using life.

Any questions or more details, please contact us anytime by the following ways.

FL2-10 Hydraulic Compressed Earth Clay Interlocking Brick Making Machine

Main Features

1. Function

FL2-10 atomatic brick making machine can produce different shapes interlocking bricks by changing mould. Besides, the mould can be designed according to the need of customer.

2. High production efficiency

This clay interlocking compressed earth soil block brick making machine is a high efficient machine and the shaping cycle is 10s. The production can start and finish just by pressing start button, so the production efficiency is high with labor saving, it can produce 5760 pieces bricks per 8 hours.

3. Advanced technology

Hydraulic pressure molding technology is adopted by this machine, and the pressure can arrive at 40 MPa, so the blocks produced are of good quality, large density and high strength.

4. High quality mould

The company adopts the most advanced cutting technology and heat treatment technology to ensure product quality and ensure customers' ease.

Advanced technology

Hyraulic pressure molding technology adopted to assure the steady running of brick machine. Bricks produced are of larger density and higher strength.

Ectromagnetic valves

Solenoid valve will use YUKEN brand which is the

biggest electromagnetic valve manufacturer in Japan to

assure brick making machine run stably.

Brick mould

Soil mixer is installed in the machine which supply the material in time .All the power is provided by the hydrauliac system

PLC Control

1. Select original Mitsubishi PLC control system and famous brand relay to assure stable and high-efficiency working status of the machine.

2. It is a a functioning and flexible application and has high reliability, strong anti-interference ability.

3. Easy to learn and operate.

FL2-10 full automatic clay interlocking brick making machine can produce various different bricks by changing mould. The following bricks are some common brick types. We can also customize the brick mould according to your specific requirements.

Our Company

FULANG Machinery Group Co.,Ltd .is a Chinese manufacturer of dedicated machinery for construction blocks and panels.Our company offers complete production lines for premium building components such as the autoclaved sand -lime brick, autoclaved aerated concrete brick,and autoclaved aerated concern/autoclaved lightweight concrete panel.Additional,we provide various types of pressure vessels and block-making machines.By choosing FULANG,customers can enjoy professional benefits with our dedicated services for design,install,layout planning,technology transfer,and production guidance.

Customers visiting

With 19 years development ,our products have been sold to more than 80 countries.Till now,about 1200 customers have visited our factory.Also we have engineers stay abroad to help you install the machines and training your workers at your side.

The FAQ

1.Q: What kind of payment terms do we accept?

A:T/T and L/C are common for us. Other ways are ok by negotiation.

2.Q:How about your Production time ?

A: Normally 20-25 days after your deposit.

3.Q: Can I visit your factory?

A: Yes. Many domestic and international customers visit our factory every year.

4.Q: Do you provide after-sale service?

A: Yes. We have a professional after-sale service team to promptly and thoroughly solve your problems.

Our Service

Pre-Sales

1.Perfect 7*24 hours inquiry and professional consulting services.

2.Visit our factory anytime.

Sale

1.Update the production schedule in time.

2.Quality supervision.

3.Production acceptance.

4.Shipping on time.

After-Sales

1.Warranty period : 2 YEAR after acceptance, during this period we will offer free spare parts if they are broken.

2.Training how to install and use machine.

3.Engineers available to service overseas.

4.Skill support the whole using life.

Any questions or more details, please contact us anytime by the following ways.