- Product Details

- {{item.text}}

Quick Details

-

Power:

-

15-70Kw depends on size

-

Dimension(L*W*H):

-

TBD

-

Weight:

-

600 KG

-

Appearance:

-

Stainless steel or Red Copper clading

-

Thickness of Tanks:

-

3mm for interior shell/2mm for exterior shell

-

Color Available:

-

Mirror SUS, Luxury red copper

-

Heating:

-

Electric/Steam/Direct fired

-

Heat Insulation:

-

Polyurethane or Rockwool with Thickness=80mm

-

Inner Polishing Precision:

-

0.4 Micrometer

-

Volume Design:

-

Properly according to the capacity request

-

Controlling System:

-

Temperature, Pressure auto control

-

After-sales Service Provided:

-

Field installation, commissioning and training

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tiantai/TBE or OEM

-

Voltage:

-

3phase/380(220,400,415,440)v/50 (60)Hz

-

Power:

-

15-70Kw depends on size

-

Dimension(L*W*H):

-

TBD

-

Weight:

-

600 KG

-

Appearance:

-

Stainless steel or Red Copper clading

-

Thickness of Tanks:

-

3mm for interior shell/2mm for exterior shell

-

Color Available:

-

Mirror SUS, Luxury red copper

-

Heating:

-

Electric/Steam/Direct fired

-

Heat Insulation:

-

Polyurethane or Rockwool with Thickness=80mm

-

Inner Polishing Precision:

-

0.4 Micrometer

-

Volume Design:

-

Properly according to the capacity request

-

Controlling System:

-

Temperature, Pressure auto control

-

After-sales Service Provided:

-

Field installation, commissioning and training

1800L 18HL 15BBL complete direct fire heating two vessel brewhouse buy microbrewery equipment beer brewing machine

Part 1

General Description of 18 00L Brewhouse

------ Quality Design for Craft Brewing

1. Introduction

The 1800L 18HL 15BBL complete SUS304 direct fire heating two vessel brewhouse is often used in microbreweries. The system contains three brewhouse vessels, a m ash tun / lauter tun and a boiling/whirlpool tun . The mashing process and the wort filtration process are completed by Mash tun/ lauter tank; The boiling and whirlpool processes are completed by one tank.

This system usually brews two or three batches a day. According to different fermentation cycles of brewed beer, 6pcs 35 00L fe rmenters or 12pcs 18 00L fermentors can usually be configured, and 4pcs 35 00L fermenters and 4pcs 18 00L fermenters can also be configured to meet the needs of various beer types.

The system also needs to be equipped with a complete automatic or manual control system , malt milling system , CIP system , cooling system , steam heating system , air system , etc.

2. Our Advantage

> With ISO TUV SGS, the product meets the GB/

CE/PED/ASME

standard

>

Local service

in EUROPE, AUSTRALIA ETC

>

5 Years

Warranty for tanks

>

0 trade risk

verified by more than 1100 breweries

> 20 Years Manufacture and Management Experience

3. Features

> Two vessels with hot water,

18

00Liter/batch

, first batch takes about 8 hours, and two batches of 14 hours are allowed;

> All certificated

304

stainless steel, easy to clean; Copper cladding for special environments such as bars;

>

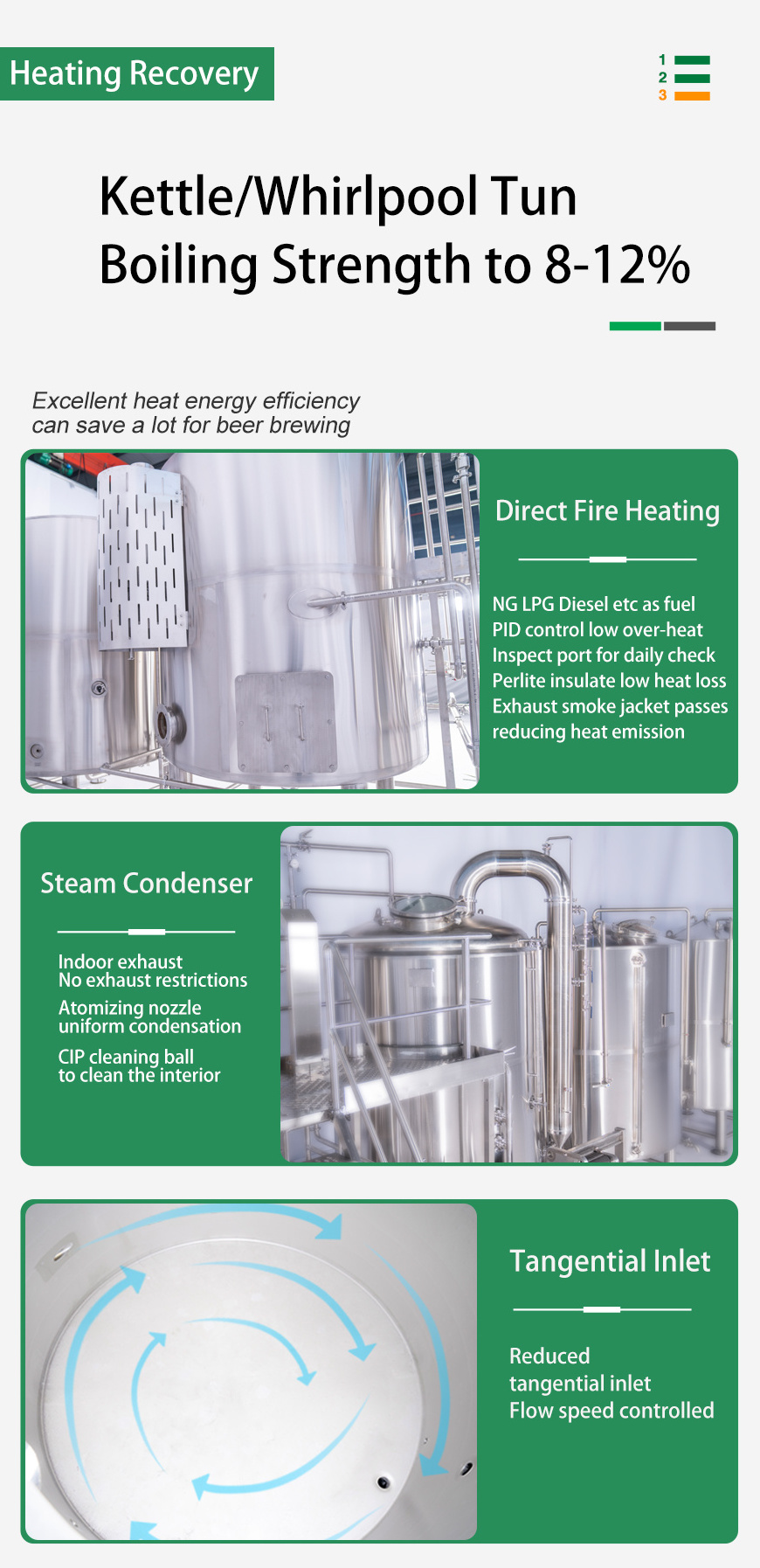

Direct Fire

heated,

high thermal efficiency,

save space and cost

; Electric or

Steam

heating available;

> The

wort cooled

by tap water and -5 ºC ice water to cool in two stages, Single stage available;

> Mashing heating and fermentation cooling

automatically controlled

, and manual control switched at any time;

> Manual valve control, humanized operation, low equipment investment cost, high cost performance; PLC automatic control for upgrade;

4. Parameters

|

Design Basis

Ingredients: Malt Mashing: Infusion & Decoction OG: 12 Plato Boiling Strength: 8%-10% |

Energy Consumption

Heating: Direct Fire Burner Capacity : 150KW /hr or 360000BTU/h Power: about 9KW Water: Hot water recovery |

|

Dimension

Mash Tun/ Lauter Tun: Φ 16 60mm Kettle/Whirlpool Tun: Φ1 6 60mm Floor Space:about 7 0 00*6 5 00mm |

Controlling

Control Panel:PLC Auto Screen Brewing Valve:Pneumatic CIP Valve:Manually Manifold Temperature:PLC Auto Control |

5. Components

|

18HL Mash/Lauter Tun |

1set |

|

18HL Kettle/Whirlpool Tun |

1set |

|

35HL Hot Water Tank |

1set |

|

Non-slip Work Plateform |

1set |

|

Sanitary Centrifugal Pump [LYSF] |

2sets |

|

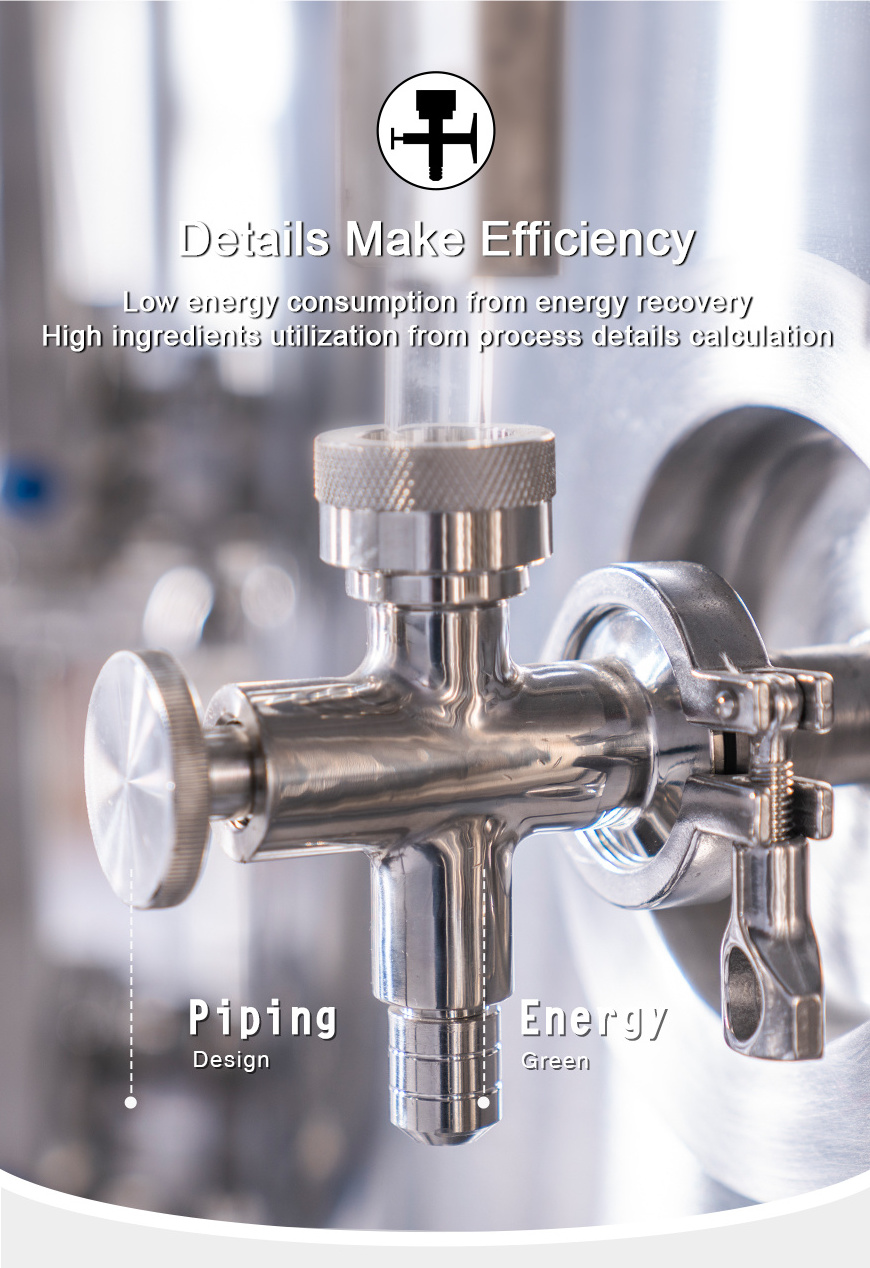

Sanitary Piping |

1set |

|

Valves and Fittings |

1set |

|

Manual Water Mixing Station |

1set |

|

Manual Wort Cooling Station |

1set |

|

Pipeline Instrument Sensor |

0unit |

|

25L Glass Wort Grant |

1set |

|

20M2 Heat Exchanger [304SS NANHUA] |

1set |

|

Pipe Filter |

1set |

|

Wort Aeration Station |

1set |

|

30L Yeast Feeder |

1set |