- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1550*1150*1520mm

-

Weight:

-

2000 KG

-

Material:

-

stainless steel, metal

-

Material sheet stamping:

-

sheet 0.8-1.5mm

-

Billet size (sheets):

-

1250 mm x 2500 mm

-

Depth footprint:

-

50 microns = 1/20 mm = 0,05 mm

-

Speed stamping:

-

not less than 3 metres per minute

-

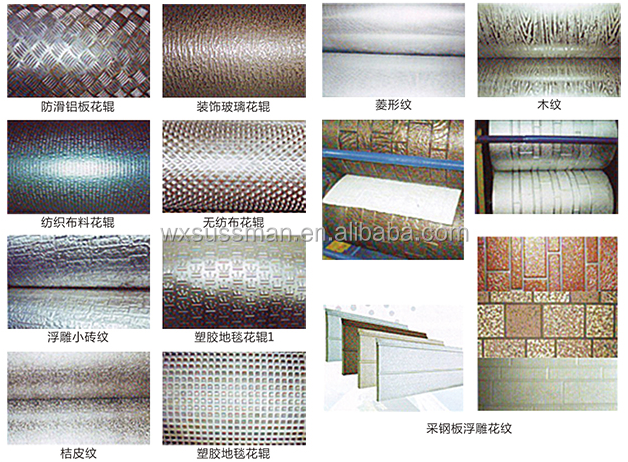

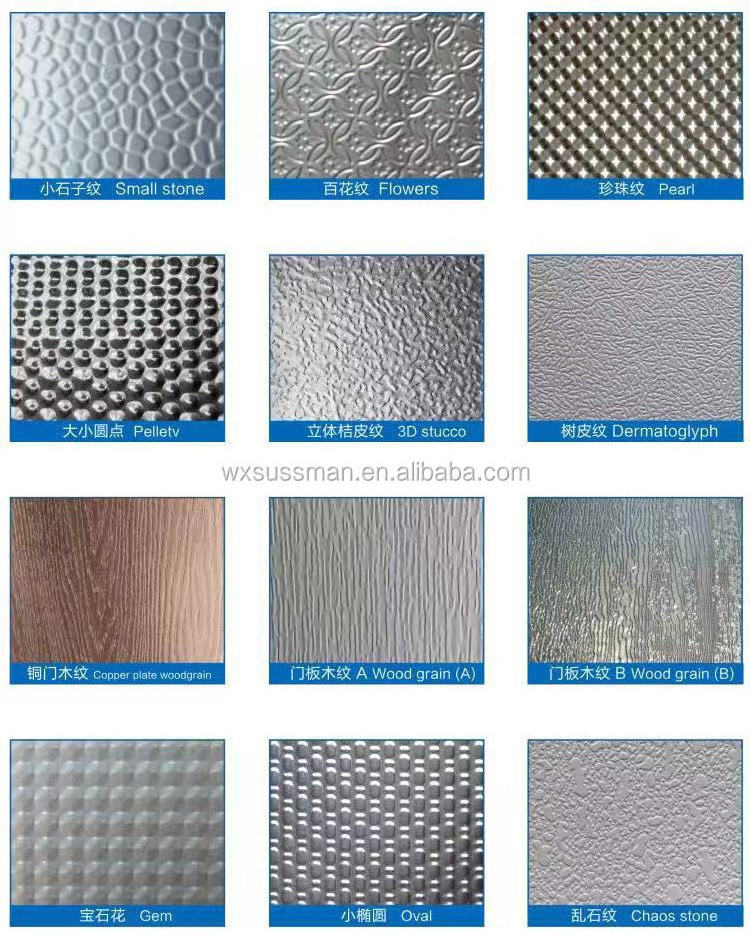

Roller type:

-

a variety of flower design

-

Type of stamping:

-

unilateral model rolling

-

Color:

-

as requirement

Quick Details

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sussman

-

Dimension(L*W*H):

-

1550*1150*1520mm

-

Weight:

-

2000 KG

-

Material:

-

stainless steel, metal

-

Material sheet stamping:

-

sheet 0.8-1.5mm

-

Billet size (sheets):

-

1250 mm x 2500 mm

-

Depth footprint:

-

50 microns = 1/20 mm = 0,05 mm

-

Speed stamping:

-

not less than 3 metres per minute

-

Roller type:

-

a variety of flower design

-

Type of stamping:

-

unilateral model rolling

-

Color:

-

as requirement

Embossing machine spefication

Our company specialized in designing and making metal sheet embossing machinery,there are many series of steel embossing machine which are suitable to you.

|

Model

|

S1000

|

S1400

|

S1600

|

S1900

|

|

Overall size(mm)

|

2900*1200*1500

|

3300*1200*1500

|

3500*1200*1500

|

3800*1200*1500

|

|

Roller size

|

φ350*1000mm

|

φ380*1400mm

|

φ400*1600mm

|

φ450*1900mm

|

|

Material of roller

|

42CrMo

|

42CrMo

|

42CrMo

|

42CrMo

|

|

Roller hardness

|

HRC55-58

|

HRC55-58

|

HRC55-58

|

HRC55-58

|

|

Way of embossing

|

Both up and down rollers embossing

|

Both up and down rollers embossing

|

Both up and down rollers embossing

|

Both up and down rollers embossing

|

|

Embossing regulation

|

By screw

|

By screw

|

By screw

|

By screw

|

|

Motor power(KW)

|

7.5

|

11

|

15

|

15

|

|

Line speed

|

0-18m/min

|

0-30m/min

|

0-40m/min

|

0-45m/min

|

1.The hydraulic tank must be filled with 32# or 46# hydraulic oil before using. The amount of oil is subject to the oil mark

2. Add and daub lube often to the outside parts. (Such as driving chain,Scissors, gears, rollers, )

3. Wipe the surface dust of roller often and particularly work outside. If you do not use it for long time ,you should daub

machine and lube in the roller surface and you need clean it when you use next time.

4. If the equipment does not use for long time, you should use plastics cloth or other articles to cover it and notice to avoid

rain and damp, especially electrical controlling box

5. Cutting device should add lube to the places where need lube to the request

6. Usually look into hydraulic station and the oil quantity of deceleration machine, you should add in time when oil quantity

shortage

7. Electrical components should be guaranteed to work in a dry environment, such as damp. Rain should continue to work after drying.

Before loading to the container, we will check the machine first

Second, make some protection on the machine, Such as, we will mpaint the coil on the roller and shaft, in case the roller and shast got corrosion and rusty during long time delivery

Third, we will make the plastic package on the easy damage parts, and fix all the parts into container by the steel wire rope, and ensure the machine will not damage when shaking on sea.

At last, we will take photos for customer when loading to container

Sussman Machinery has exported its equipment and machines to more than 80 countries over the world, such as Russia, India, Australia, Malaysia, Nigeria, Romania, South Africa,Mauritius,Mexico,etc. It has received excellent reputation. In the future, we are committed to better equipment and sales service and meeting customers' requirements when and where they need.