Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SH

-

Model Number:

-

Pu Sandwich Panel

-

Product name:

-

Fireproof exterior roof wall 20mm 50mm polyurethane pu sandwich panel

-

Size:

-

50-200*1000*11800mm or Customized

-

Color:

-

Bright red,vermilion,lime,sky blue,aquamarine,pea green or customized

-

MOQ:

-

500 square meters

-

Function:

-

Thermal Insulation,Soundproof,Earthquake proof,Eco-friendly

-

Keyword:

-

Fireproof Insulation Sandwich Panels

-

Advantage:

-

Fierproof and waterproof easy to install

-

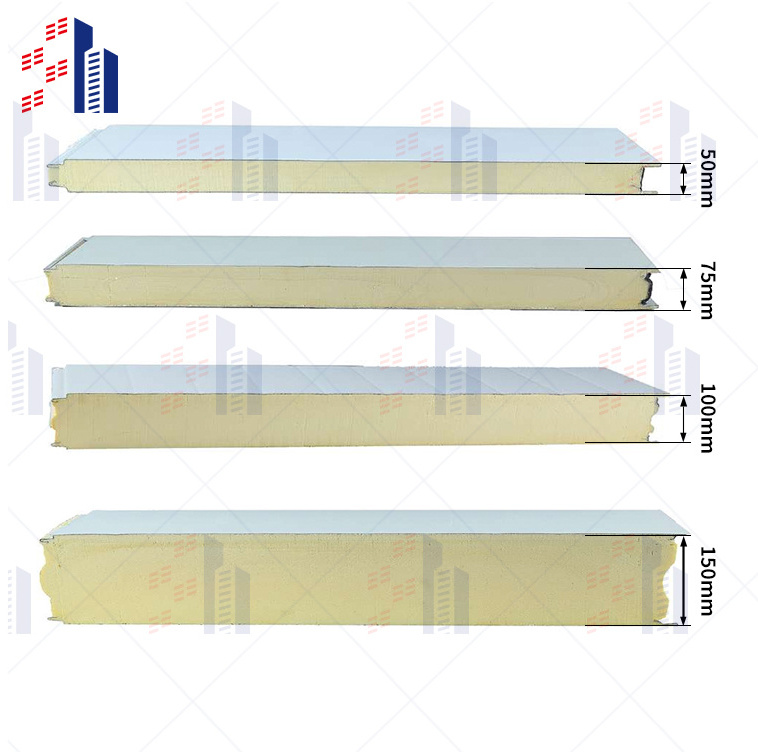

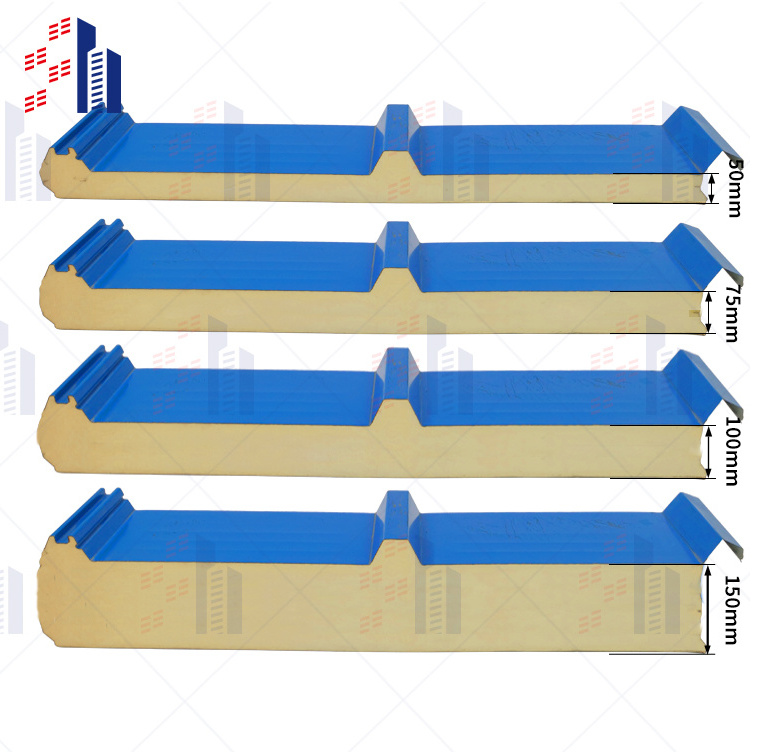

Thickness:

-

50/75/100/150/200mm or customized

-

Certificate:

-

CE/ISO

Quick Details

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation, Others

-

Application:

-

Hotel/Wall Partition/buildings, Office Building, Workshop, Farmhouse, Courtyard, wall panel

-

Design Style:

-

Modern

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SH

-

Model Number:

-

Pu Sandwich Panel

-

Product name:

-

Fireproof exterior roof wall 20mm 50mm polyurethane pu sandwich panel

-

Size:

-

50-200*1000*11800mm or Customized

-

Color:

-

Bright red,vermilion,lime,sky blue,aquamarine,pea green or customized

-

MOQ:

-

500 square meters

-

Function:

-

Thermal Insulation,Soundproof,Earthquake proof,Eco-friendly

-

Keyword:

-

Fireproof Insulation Sandwich Panels

-

Advantage:

-

Fierproof and waterproof easy to install

-

Thickness:

-

50/75/100/150/200mm or customized

-

Certificate:

-

CE/ISO

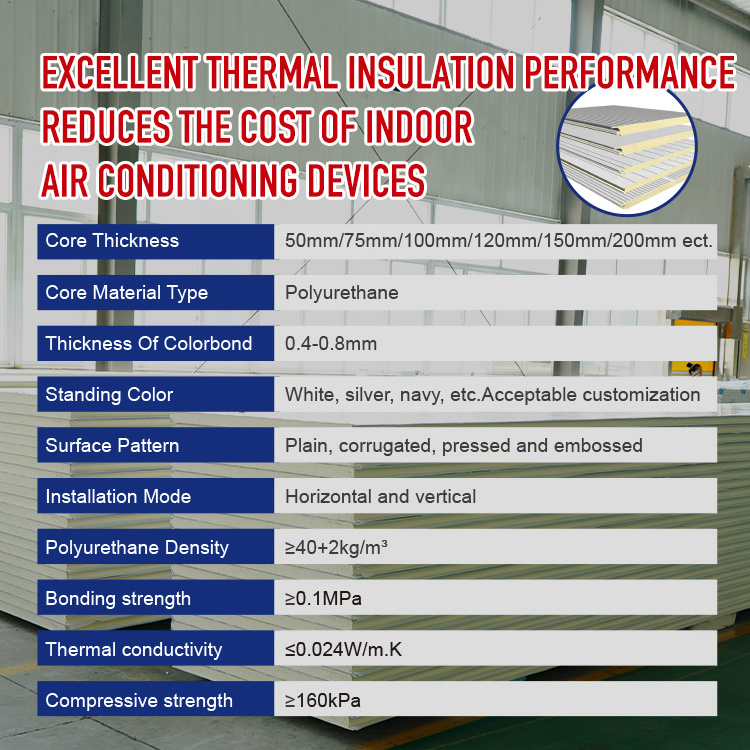

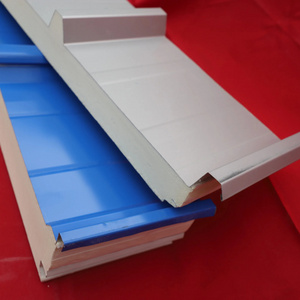

Prefab house fire rated fireproof interior exterior roof wall 20mm 50mm polyurethane pu sandwich panel

Polyurethane sandwich panel is a polyurethane thermal insulation sandwich panel for construction, also known as anti-leakage sandwich roof panel, polyurethane rigid foam insulation panel, polyurethane composite panel, PU panel, etc. It is a highly efficient and energy-saving building envelope material with a wide range of uses and great potential, and it is also a new type of energy-saving panel advocated and promoted by the Ministry of Construction.

|

Product Name

|

Prefab house fire rated fireproof interior exterior roof wall 20mm 50mm polyurethane pu sandwich panel

|

|

|

|||

|

Surface steel plate thickness:

|

0.4-0.8mm

|

Standard thickness:

|

50mm/75mm/100mm/150mm/200mm

|

|||

|

Basic color:

|

White gray, silver gray, sea blue, red and so on.

|

Insulation performance:

|

Heat transfer coefficient ≤0.025W (M.K)

|

|||

|

Core material density:

|

42KG/m³

|

Compressive strength(Kg/m²):

|

0.2-0.7

|

|||

|

Recommended galvanized layer:

|

150/m² Hot aluminum zinc plating

|

Installation method:

|

1. Horizontal (horizontal) 2. Vertical (vertical)

|

|||

|

*We can select the thickness of internal and external steel plate, coating and steel plate manufacturer according to customer demand.

|

|

|

|

|||

Product Details

Fire performance:

Grade B combustion performance, the highest operating temperature is 180°C (250°C for instant elbow), carbon formation under the direct action of the flame, no dripping, no curling, no melting phenomenon, the surface forms a layer after the flame burns "Graphite Foam" layer, which effectively protects the foam structure within the layer.

The degree of prefabrication and assembly is high, and the construction is less affected by harsh weather. Therefore, compared with the traditional construction method, the construction period can be shortened by more than 40%.

Strength, stiffness, stability, washout resistance, good shock resistance, corrosion resistance and atmospheric resistance. It can be used to maintain the structure and load-bearing structure. Generally, the house does not need beams and columns.

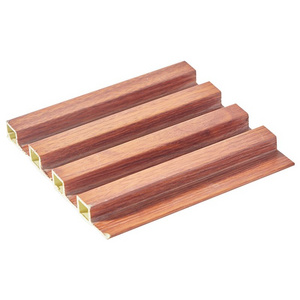

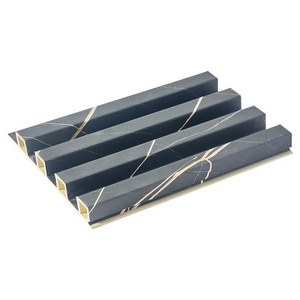

Wall Panel system

Thermal insulation performance:

The thermal insulation performance of the polyurethane sandwich panel is better among the three.

Under the premise of the same energy saving index, the thickness of the thermal insulation board can be reduced and the quality stability of the thermal insulation system can be improved.

Under the premise of the same energy saving index, the thickness of the thermal insulation board can be reduced and the quality stability of the thermal insulation system can be improved.

Thermal stability:

The thermal stability of rigid foam polyurethane can be as high as 120 °C, while the styrene board is only 70°C. In this way, above a certain temperature, it is easy to cause secondary foaming of the benzene board, resulting in cracking of the board seam.

Combustion principle:

Rigid foam polyurethane is a thermosetting material, which forms a carbonized layer after being heated and burned, which blocks the further penetration of heat and oxygen, hinders the further combustion of the foam, and is not easy to cause fire spread accidents. Polystyrene foam is a thermoplastic material, which shrinks and melts after being heated, and then drips and burns. It cannot produce a carbonization barrier layer, and it is very easy to cause flame spread and flashover

accidents. However, flame retardants are often added to polystyrene foams to achieve the required flame retardant grade.

accidents. However, flame retardants are often added to polystyrene foams to achieve the required flame retardant grade.

The scope of application is different:

Polystyrene foam can only be molded and extruded in the factory state, while rigid polyurethane foam can be sprayed, poured and factory foamed, so the application methods and application fields are more diverse and convenient than polystyrene foam.

Roof Panel System

Features/Advantages of Roof Sandwich Panels:

A.

The roof panel has good fire resistance, heat insulation and air tightness. The air port between the panels is embedded in the lap structure and the application of the hidden screw technology to achieve rapid roof construction without leakage. It is an energy-saving building envelope with excellent performance.

B.

The large-sized reinforcing rib design on the surface greatly increases the span space and saves the sandalwood structure.

C.

Lightweight roofing material, saving structural and installation costs.

D.

Factory prefabricated to meet all-weather construction requirements and shorten the installation period.

E.

There is a sealing strip at the lap joint between the boards to ensure the airtightness of the roof.

F

.

Hidden screw installation structure to solve the problem of roof leakage.

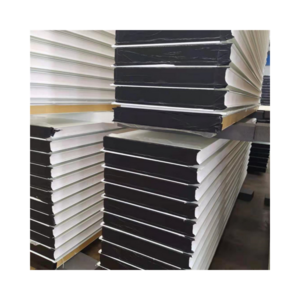

Production Workshop

The composite board with polyurethane as the core material is composed of upper and lower color steel plates and intermediate foamed polyurethane. It adopts the world's advanced six-component online automatic operation mixing and pouring technology, which can complete the mixing process of the batching center or the factory at one time online. It can be adjusted at will according to the temperature online, so as to produce distinctive high-strength, energy-saving and green building panels.

Product Application

The formed panels have high-quality fire safety, thermal insulation, environmental protection and other characteristics, providing an excellent choice for public building envelope system software. Under the premise of considering the requirements of building heat insulation, sound insulation, fire safety and other regulations, it has achieved high quality, high efficiency, reliability and safety. overall goal.

Polyurethane sandwich panels are widely used in large industrial plants, cold storages, garages, mobile houses, exhibition halls, gymnasiums, shopping centers, airports, power plants, villas, hospitals, strata and high-rise office buildings, etc. For roofs and walls of industrial and civil buildings.

Company Introduction

At present, we have established good partnerships with buyers all over the world.

Mainly exported to Southeast Asia, South America, North America, Europe and West Africa.

We have a wide range of buyers, builders, dealers and Amazon sellers.

We do our best to serve every customer and constantly open up new areas.

Looking forward to cooperating with you.

The installation of Shanghe metal sidings has low requirements for the condition of wall and the weather. It can be conducted in all seasons, which greatly shortens the construction period and reduces the project cost.Therefore, whether the original wall is painted or fixed with tiles, the metal siding can be directly installed on the original wall, which simplifies the process of installation and shortens the construction period. In addition to excellent decorative performance, Shanghe metal sidings also have good energy-saving and thermal insulation effect.Imported equipment are adopted to produce such metal sidings. With high quality, high standards, and stable performance,Shanghe metal sidings are the wise choice for energy-saving renovation of exterior walls.

FAQ

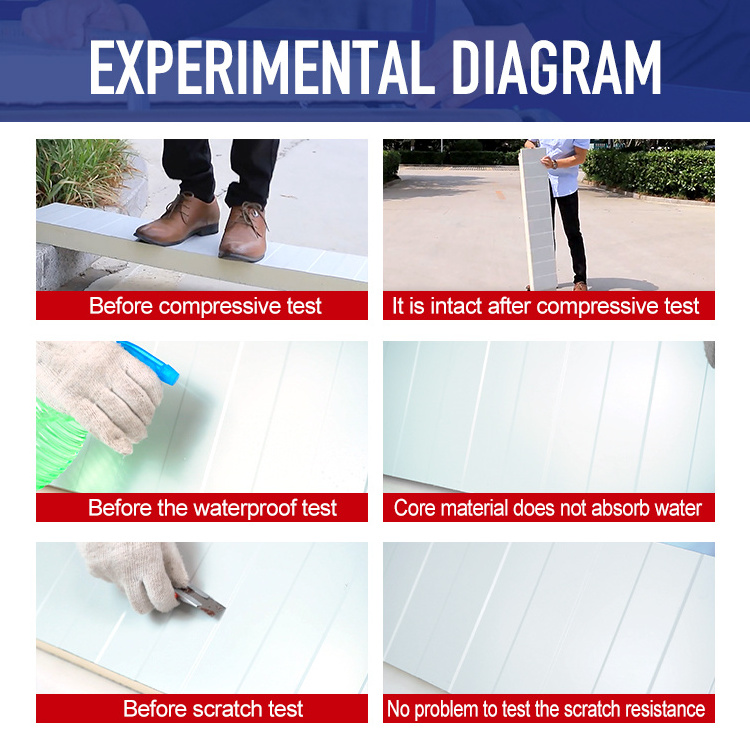

Q:What precautions should be taken during the construction process?

A:①Tear off the film after construction to prevent rainwater from immersing into the corroded board surface.

② After the construction is completed, the iron filings and sundries on the board should be removed in time to avoid rust on the board after rain.

③ Avoid other hard objects from scratching the surface coating.

④ During the handling process, the force on the board surface should be uniform, and the supporting points should be uniform. Note that it is strictly forbidden: when taking the upper and lower boards, it is strictly forbidden to directly drag and transport the board and the board (to prevent the burr at the cutting place from scratching the surface and affecting the effect of the product on the wall)

⑤ When the site needs to be cut, the cutting place must be cleaned up.

Q:

How to store polyurethane insulation sandwich panel?

A: Polyurethane has good corrosion resistance, and the only thing that destroys it is ultraviolet rays, so pay attention to prevent sun exposure and avoid storage in the open air. Such as long-term storage, should be stacked stacked.

A: Polyurethane has good corrosion resistance, and the only thing that destroys it is ultraviolet rays, so pay attention to prevent sun exposure and avoid storage in the open air. Such as long-term storage, should be stacked stacked.

Q:

What is the working temperature of polyurethane insulation panel?

A:

The temperature range of polyurethane insulation board is between -30°C and +90°C, and the short-term use temperature can reach +250°C without any damage.

Q:

Can polyurethane insulation board resist thermal deformation?

A:

Any material undergoes a dimensional change under the action of temperature. When the density of non-veneer rigid polyurethane foam is 30~60Kg/m3, the thermal expansion coefficient is 5~8·10-5·K-1. When the temperature rises, for example, from 10°C to 30°C (temperature difference = 20K). Rigid polyurethane foam insulation boards over one meter can expand 1~1.6mm, which is normal.

Q:Can I get samples for inspection?

A:We will provide free samples to you before order confirmation.

Q:Can I get samples for inspection?

A:We will provide free samples to you before order confirmation.

Hot Searches