- Product Details

- {{item.text}}

Quick Details

-

Usage:

-

Aimal Bedding

-

Capacity:

-

1000kg/h

-

Application of shaving machine:

-

Special Packing

-

Type:

-

Widely Used Wood Shaver

-

Qty of blades:

-

8 pcs

-

Feeding inlet size:

-

280*200mm

-

Main shaft speed:

-

400r/min

Quick Details

-

Place of Origin:

-

Henan, China

-

Name:

-

Jumbo output wood shaving making machine

-

Raw materials:

-

Wood Material

-

Usage:

-

Aimal Bedding

-

Capacity:

-

1000kg/h

-

Application of shaving machine:

-

Special Packing

-

Type:

-

Widely Used Wood Shaver

-

Qty of blades:

-

8 pcs

-

Feeding inlet size:

-

280*200mm

-

Main shaft speed:

-

400r/min

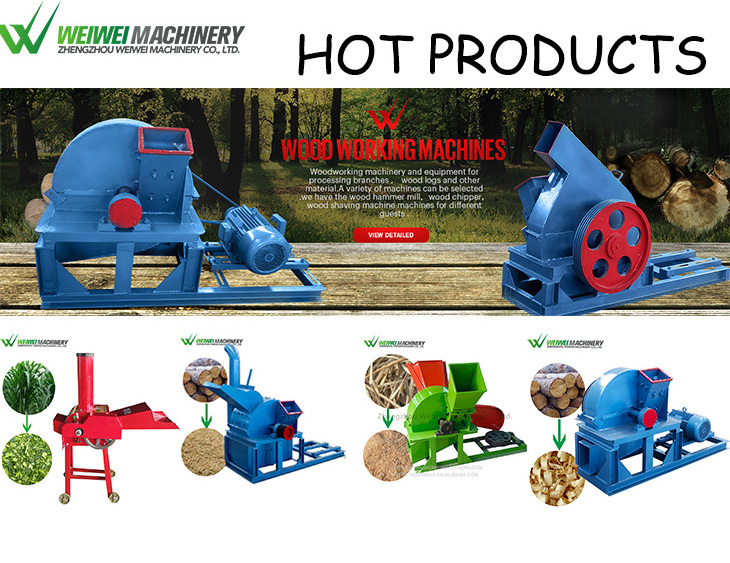

Weiwei 30years manufacturer wood shavings machine for horse bedding

The manufacturing process of wood shaving machine is combined with the previous experience and the present innovation made, and the automatic feeding system, the thickness of the material can be adjusted.

The advantages of compact structure, reasonable layout, convenient installation, convenient operation and maintenance

Product Parameter

|

MBJ800 |

|

|

Weight |

800kg |

|

Main shaft speed |

400r/min |

|

Power |

30-37KW |

|

Blade ( moving blades ) |

8pieces |

|

Capacity |

500-1000kg |

|

Product size |

1850*800*1400mm |

|

Feeding inlet size ( Diameter of raw material ) |

280*200mm |

|

Power equipment |

Electric motor , diesel engine , trailer mounted |

-

The feeding port adopts automatic feeding device

-

Cutter head.The cutter is composed of thick steel plate and changed the original fragile

-

The cutting blade adopts high quality alloy cutting tools

-

Extensive feed port and fixed blades

-

The main part of the machine is through the dynamic balancing equipment

-

The machine is a new type of woodworking machinery and equipment.

-

mainly used for mass production of uniform thickness flakes, is a kind of automatic shaving machine (wood shaving machine) can be sticks,twigs, branches and logs can be used as processing

-

shaving machine produced wood furniture factory and produced wood is the same.

-

This machine adopts automatic feeding device

-

compared with the traditional simple operation, but also increase the particle produced speed, saves manpower and time

-

The feeding port adopts automatic feeding device

The feeding port adopts automatic feeding device, the wood timber go through feeding port into machine, the wood be cut by blade(cutter), then be blow out of the machine by fan blade of cutters, then users can get uniform wood shavings.

Cutter head

The cutter is composed of thick steel plate and changed the original fragile, increase the service life of the machine, fan design is enhanced in the machine running speed of wood, wood from the machine speed and easy to sieve out the whole cutter head, smooth operation, regrinding the wood

The cutting blade adopts high quality alloy cutting tools. The cutters are hard, wear resistant, cutting sharp, difficult to rust, corrosion resistant, and the service life is longer than the general steel cutting tools, the output of wood crusher is larger .

Extensive feed port and fixed blades

The machine adopt extensive feed port and it is convenience for raw materials, Meanwhile,it also increasing the yield. The thickened fixed blades are made of steel and installed on the inlet hopper, unique design, fixed knife working with cutter to complete wood shavings process

The main part of the machine

The main part of the machine is through the dynamic balancing equipment, each machine's weight error range is less than 15g, so that the machine can run smoothly,reduce noise, improve production efficiency, prolong the service cycle, low cost, high yield, is the mature technology of wood processing machinery

Use motors, diesel engines, tractors, trailer mounted as matching power