- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

NAH

-

Place of Origin:

-

Hebei, China

-

Product name:

-

Slurry Pump

-

Type1:

-

Horizontal Slurry Pump

-

Type2:

-

Vertical Slurry Pumps

-

Type3:

-

Submersible slurry Pumps

-

Material:

-

High Chrome Alloy

Quick Details

-

Application:

-

Industrial Utilities, Metal and Equipment Manufacturers, Mining industry, Wastewater Transport and Flood Control, wastewater treatment, Water Treatment Solutions

-

Warranty:

-

1 years

-

Brand Name:

-

naipu

-

Model Number:

-

NAH

-

Place of Origin:

-

Hebei, China

-

Product name:

-

Slurry Pump

-

Type1:

-

Horizontal Slurry Pump

-

Type2:

-

Vertical Slurry Pumps

-

Type3:

-

Submersible slurry Pumps

-

Material:

-

High Chrome Alloy

NAIPU Silicon Carbide SiC Ceramic Slurry Pump

Shijiazhuang NaiPu Pump Co.,Ltd --- Direct factory of slurry pump, gravel sand pump , dredging pump and Spare parts . With more 30 years experience.

The pump and spare parts can totally interchange with NAH HH M L SP AF G Series.

We also can produce wear parts(High Charome alloy material) according to the drawing or sample.

Wet parts in material silicon carbide (SiC) ceramic.

3~8 longer lifetime than metal pump!

Why to Choose SiC Ceramic Slurry Pump?

- Abrasion resistance 4 times of high chrome

- Corrosion resistance to PH0-12 nearly all acid and alkali

- Impact resistance to large solids

- 3~8 times longer lifetime than metal pump

- Energy saving and cost reducing >20% -40%

Why to Choose

SiC Ceramic Slurry Pump

?

-

A

brasion resistance 4 times of high chrome

-

C

orrosion resistance to PH0-12 nearly all acid and alkali

-

I

mpact resistance to large solids

- 3~8 times longer lifetime than metal pump

-

E

nergy saving and cost reducing >20% -40%

Seal Type:

-

G

land seal /

P

acking seal

-

E

xpeller +

G

land seal

-

M

echanical seal

Structure of SiC Slurry Pump series:

1.The wet parts are made with sintered SiC ceramic, which is sintered in automatic nitriding furnace at termperature 1400ºC.

2.The wet parts and frame are connected by bolts, so customers can adjust the direction of pump discharge according to his requirement.

3.Bolts on the frame is used to adjust the gap between impeller and throat bush, in order to achieve high efficiency working.

4.For dealing with abrasive and corrosive fluid, mechanical spring is set outside in case of blocking. Stationary Design is adopted when the axle diameter is large and linear velocity is high.

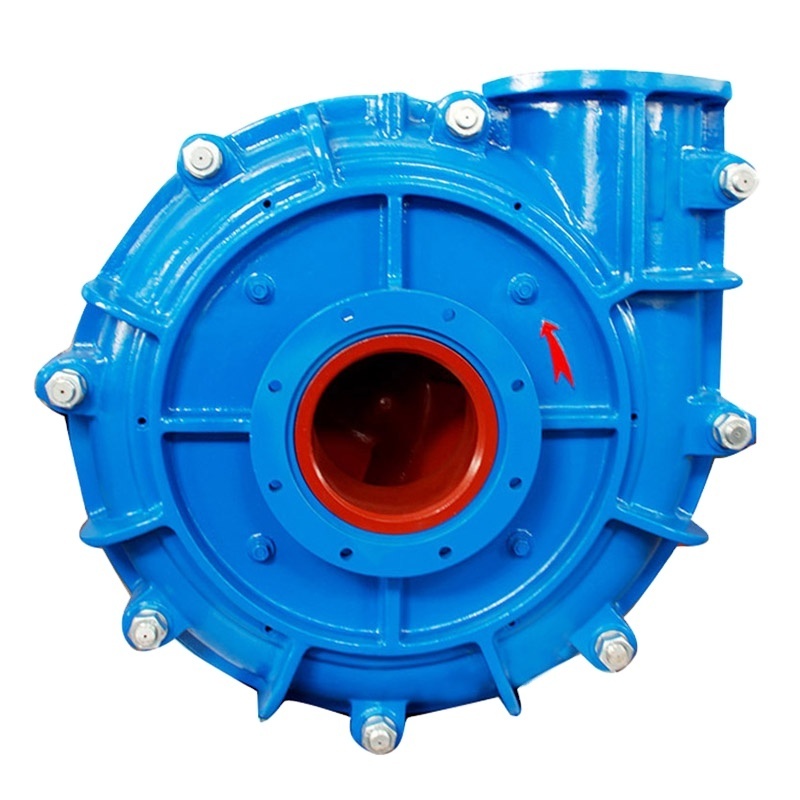

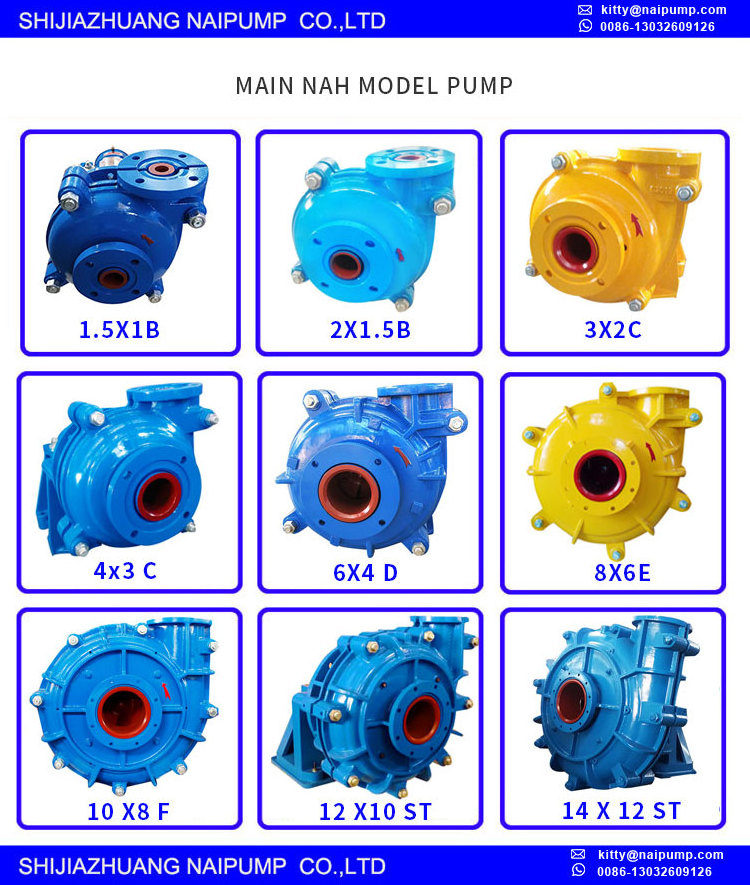

Metal Liner Heavy Duty Slurry Pump NAH TYPE

1.5/1B-NAH 2/1.5B-NAH 3/2C-NAH 3/2CC-NAH 4/3C-NAH 4/3CC-NAH 4/3D-NAH 4/3DD-NAH 6/4D-NAH 6/4DD-NAH 6/4E-NAH 6/4EE-NAH 8/6E-NAH 8/6EE-NAH 8/6F-NAH 8/6FF-NAH 8/6R-NAH 10/8ST-NAH 10/8F-NAH 10/8FF-NAH 12/10ST-NAH 12/10G-NAH 12/10F-NAH 12/10FF-NAH 14/12ST-NAH 14/12G-NAH 14/12FF-NAH 14/12F-NAH 16/14TU-NAH 20/18TV-NAH

Horizontal Slurry Pump Performance Parameters

|

Type |

Allowable Mating Max. Power(Kw) |

Clear Water Performance |

Impeller |

|||||

|

Capacity/Q m³/hr |

Head/m |

Speed/rpm |

Max Efficiency/% |

NPSH/m |

Nos of Vane |

Impeller Diameter/mm |

||

|

1.5X1-NP-NAH |

15 |

12.6--28.8 |

6--68 |

1200--3800 |

40 |

2--4 |

5 |

152 |

|

2X1.5-NP-NAH |

15 |

32.4--72 |

6--58 |

1200--3200 |

45 |

3.5--8 |

5 |

184 |

|

3X2-NP-NAH |

30 |

39.6--86.4 |

12--64 |

1300--2700 |

55 |

4--6 |

5 |

214 |

|

4X3-NP-NAH |

30 |

86.4--198 |

9--52 |

1000--2200 |

71 |

4--6 |

5 |

245 |

|

6X4-NP-NAH |

60 |

162--360 |

12--56 |

800--1550 |

65 |

5--8 |

5 |

365 |

|

8X6-NP-NAH |

300 |

360--828 |

10--61 |

500--1140 |

72 |

2--9 |

5 |

510 |

|

10X8-NP-NAH |

560 |

612--1368 |

11--61 |

400--850 |

71 |

4--10 |

5 |

686 |

|

12X10-NP-NAH |

560 |

936--1980 |

7--68 |

300--800 |

82 |

6 |

5 |

762 |

|

14X12-NP-NAH |

560 |

1260--2772 |

13--63 |

300--600 |

77 |

3--10 |

5 |

965 |

|

16X14-NP-NAH |

1200 |

1368--3060 |

11--63 |

250--550 |

79 |

4--10 |

5 |

1067 |

|

20X18-NP-NAH |

1200 |

2520--5400 |

13--57 |

200--400 |

85 |

5--10 |

5 |

1370 |

Horizontal Slurry Pump Constructure

Main Part Number At The Drawing

|

032:Frame Plate

060: Intake Joint 132:Discharge Joint 083:Throatbush 110:Volute Liner 147: Impeller |

122: Stuffing Box Seal

036: Frame Plate Liner 013:Cover Plate 018:Cover Plate Liner 124: Volute Cover Seal 041: Frame Plate Liner Inser |

The parts are widely used in Main Applications: Heavy Mining | Mineral Processing | Sand and Gravel |Coal Prep | Cyclone Feeds | Aggregate Processing | Fine Primary Mill Grinding | Chemical Slurry Service | Tailings | Secondary Grinding | Industrial Processing | Pulp And Paper | Food Processing | Cracking Operations | Ash Handling | Pipeline Transport | High Velocity Hydraulic Transport |Food Processing | Explosive Sludge In Metal Smelting | River And Pond Dredging | Heavy Refuse Removal | Larger Particle Or Low NPSHA Applications | Continuous (Snore) Sump Pump Operation | Abrasive Slurries | High Density Slurries | Large Particle Slurries | Sump Drainage | Wash down | Floor Drainage | Mixing | Iron Ore | Cooper | Diamond | Alumina | Coal | Gold | Kaolin | Phosphorite | Steel | Palm | Suger | Chemical | Power | FGD | Frac Sand Blending | Construction | City Sewage | Flue Gas Desulfurization |etc.